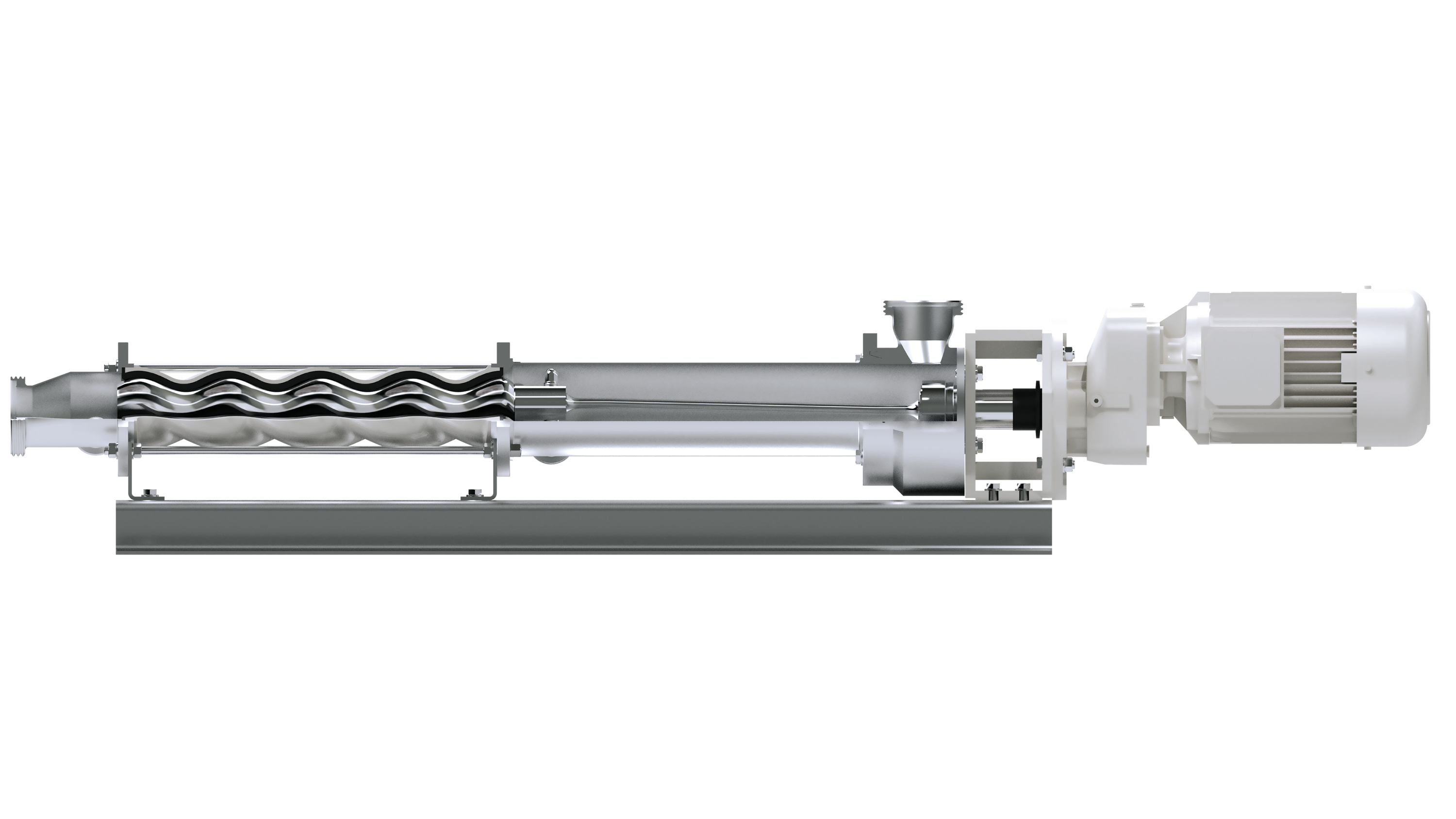

The SEEPEX EHEDG-certified progressive cavity pump range was born to meet food industry demands for equipment that adheres to strict safety and hygiene requirements without compromising product quality. This range, the BCFH, was the first hygienic progressive cavity (PC) pump to be certified by the European Hygienic Engineering and Design Group (EHEDG) under its revised testing process.

This certification guarantees residue-free cleaning at a lower temperature, with both lower chemical concentrations and a shorter cleaning time than is normal for other clean-in-place (CIP) procedures used in the food industry. As well as giving end-users peace of mind that their closed equipment is microbiologically clean, equipment designed to this standard typically requires 76% less cleaning time, saving on water, detergent and energy.

High cost of poor hygiene

Product safety is a key concern for manufacturers across a variety of industries, including pharmaceutical, chemical and food & drink. Contamination by micro-organisms such as bacteria, moulds and yeasts is an ever-present risk. Therefore, effective hygiene and cleaning regimes are essential to prevent the build-up of microbes in the processing environment, particularly in closed systems. The financial impact of ignoring this threat is significant – the Association for Packaging and Processing Technologies puts the average cost of a recall for a food company at $10m or more in direct costs, business interruption, brand damage and lost sales.

Likewise, it is essential that adherence to safety and hygiene does not adversely affect the quality of a product. The challenge, therefore, is designing cleaning regimes and equipment that provide the best possible hygienic solutions to ensure product safety without comprising on quality. This is exactly what the SEEPEX BCFH pump range has been designed to achieve.

The ultra-hygienic BCFH pump range has a low shear action, making it ideal for sensitive foodstuffs such as yogurt

Meeting tough standards

The test methods for EHEDG certification are extremely rigorous. In order to meet the required standard, BCFH pumps were used to process food that had been inoculated with microbes. The pumps were then cleaned at a lower temperature than is normal for standard CIP, before being stripped down and tested, to ensure every microbial trace had been removed.

Changes to the EHEDG certification process in recent years have made the test even more rigorous, as well as more transparent. Certification is now only valid for five years, and results are also reviewed by independent EHEDG inspectors, in addition to those that carry out the original tests. The current testing procedures guarantee that certification continues to provide end-users with complete confidence that the closed equipment they are using meets the highest possible level of hygienic design.

Ensuring brand reputation

As an established supplier of hygienic PC pumps for a wide range of applications involving product transfer with high-care requirements, SEEPEX understands that food processors must be able to rely on the hygienic credentials of their equipment to produce safe, high-quality products. Not only does this help to reduce waste and lower production costs, it also protects both public health and the brand’s reputation.

Hygienic pump design must consider not only the materials used to build the pump itself, but also its cleanability, including surfaces and rotating components. To ensure effective cleaning using CIP there must be no areas that are structurally difficult to clean and no food or microbial residues remaining after cleaning, as these will contaminate subsequent production. Automated product transfer must also be possible without any detrimental effect on product quality, either physically or microbiologically.

Preserving product integrity

Thanks to their low shear action, SEEPEX PC pumps maintain a product’s physical quality; even sensitive products such as yogurts, cream cheese, whipped cream or other colloidal mixes. Equally, they can efficiently pump viscous and sticky products, as well as those containing soft solids such as fruit or vegetable pieces. Furthermore, when used for dosing, PC pumps produce a low pulsation flow that has linear proportionality to the pump speed, allowing for easy calibration and greater accuracy. This maintains product quality, even when using a variable raw material.

In addition, the use of PC pumps can help manufacturers to lower their production costs. Alternatives such as rotary lobe or twin-screw pumps create shear, which affects consistency. Additives are then needed to compensate for this shear to ensure that sensitive products, such as yogurts, regain their original consistency. Food producers using low shear PC pumps do not need to add costly additives downstream to restore product texture and appearance.

Increased cleaning abilities

All SEEPEX hygienic PC pumps have a special surface finish and are designed to be dead-space free to prevent product from collecting in the pump. However, their hygienic BCFH pump range has a titanium flexible rod as the rotating unit, which is corrosion resistant and low maintenance. Containing no joints, the rotating unit is detachable from both the rotor and the plug-in drive shaft, making maintenance easier.