~ The automation advantage in feeder control ~

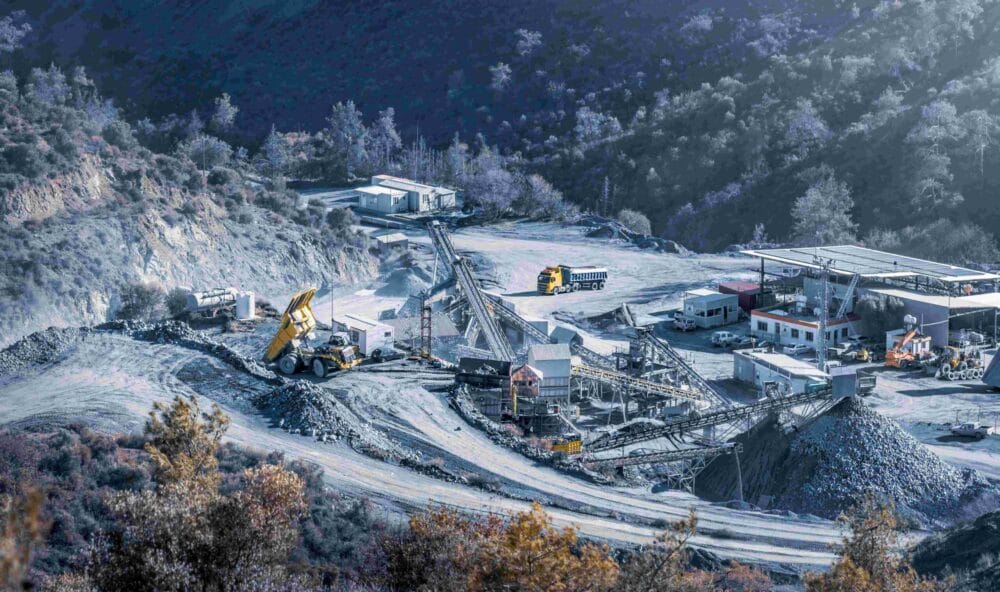

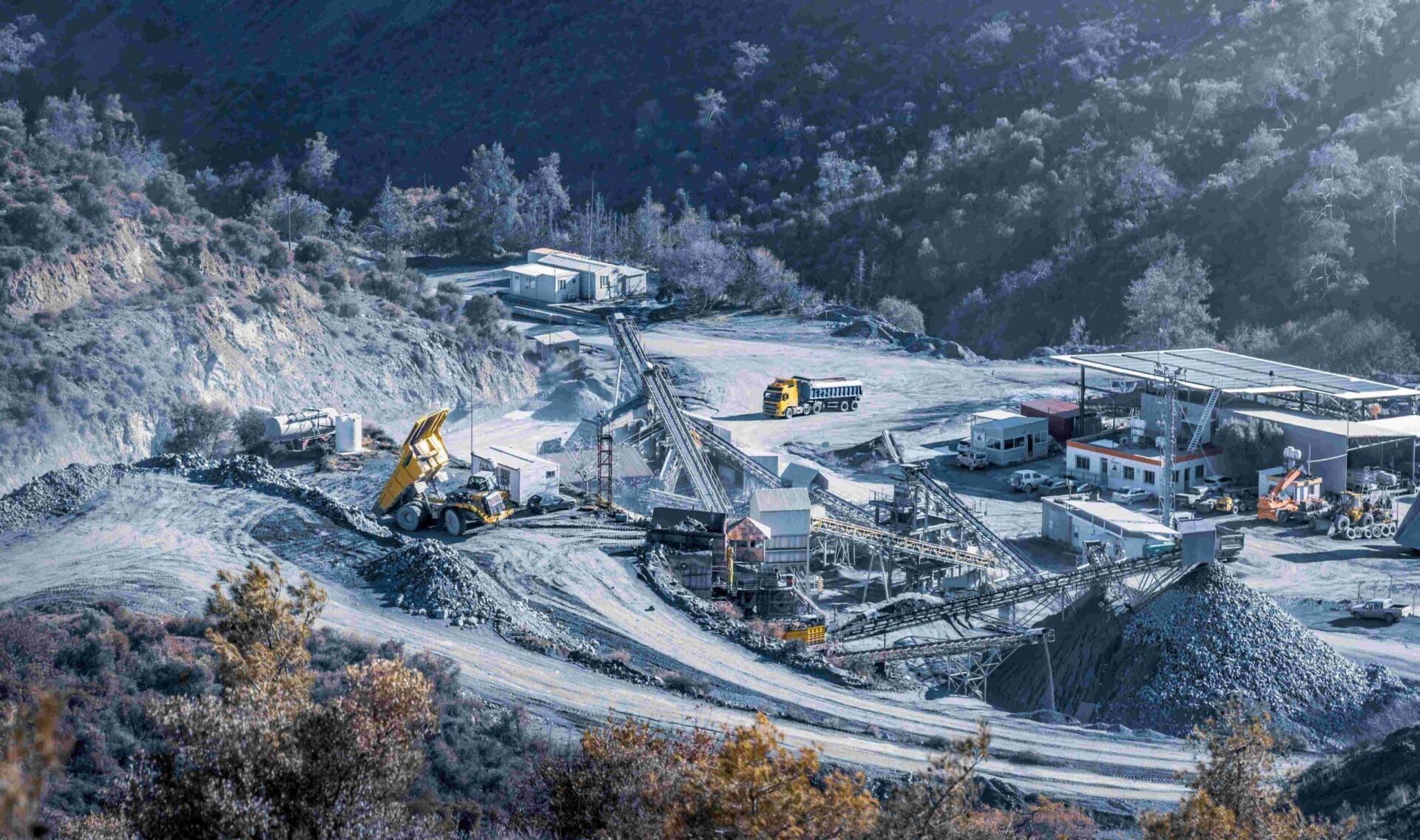

Ancient Egyptians built the Great Pyramids with huge limestone and granite blocks, cut by hand from local quarries. Fast forward to present day and quarries remain essential in supplying materials for construction and infrastructure. However, quarrying methods have significantly evolved, and today’s operations increasingly embrace automation to enhance efficiency and worker safety. Here, David Strain, technical director at integrated automation system expert, Technidrive, explains the benefits of automating feeder control in quarrying operations.

The feeding process in quarrying, whether for screening, crushing or washing, is critical for overall efficiency. Typically, a feeder, like a hopper, holds a large volume of product and gradually feeds it into the plant at a controlled rate. This rate is important, and it must match the processing capabilities of the equipment. If it doesn’t, the outcome can lead to reduced productivity.

Consider the world’s largest granite quarry in Mount Airy, North Carolina, USA. The quarry spans the size of 66 football fields and can be seen from space. In operations like this one, even small productivity gains can have significant impact for a quarry’s bottom line. And it is not just the US with colossal quarries. Demand for quarried materials is global. In fact, the Mineral Products Association (MPA), the trade association for the aggregates, asphalt, cement, concrete, dimension stone, lime, mortar and industrial sand industries has reported that, in a typical year, the UK alone uses approximately 250 million tonnes of aggregates. To meet this demand, optimisation of processes, like feed control, are key.

Limitations of manual feeder control

Manual feeder control typically involves operators using earthmoving equipment, such as dump trucks or diggers, to gradually feed materials into a hopper. This method of feeder control presents several drawbacks. Firstly, manual control relies on operators to adjust the feed rate of materials, which can lead to inconsistent speeds and inefficiencies.

Manual control is also susceptible to human error, which can result in overloading, equipment damage and consequential downtime. To avoid these problems, the operator must regulate the feeding speed based on the processing capacity of the plant. However, relying on a manual process often leads to variations in feeding rates.

The argument for automation

Automating feeder control avoids these issues and allows for precise adjustments in material flow rates. This can be based on considerations like geological conditions, such as hardness and fragmentation, allowing engineers to optimise the efficiency of the extraction and processing processes based on their in-depth knowledge of the quarry’s geography.

For example, if the material being extracted is particularly hard or abrasive, the feed rate can be adjusted to minimise wear and tear on downstream equipment. The result is improved overall productivity and lowered maintenance costs caused by equipment damage.The workforce should be a key consideration when automating quarrying operations. By automating tasks traditionally performed by people, quarry managers can significantly reduce the risk of worker accident or injury. The workforce can then be reallocated into more strategic roles like data analysis, process optimisation or equipment maintenance.

Misconceptions of automated feeding

The implementation of feeder control in quarry operations is often misunderstood. A common misconception being that higher feeder speeds lead to increased throughput.

However, optimising feeder control can actually result in higher throughput by maintaining a more constant pace — as opposed to forcing rapid feeding. If you feed at the correct speed for the equipment, then you get high levels of efficiency, and the product will be of higher quality. This method also reduces stop-start cycles and improves overall efficiency, providing an energy saving opportunity.

Deployment of automated monitoring and predictive maintenance systems can also help minimise downtime in automated feeding. These systems can detect potential issues before they escalate, reducing the likelihood of equipment breakdown and downtime.

Solutions for industry

Technidrive has developed a solution for automated feed control using technology including WEG’s CFW11 variable speed drive (VSD) and Vega 80GHz radar sensors. The system operates on a Proportional-Integral-Derivative (PID) loop feedback control system. A PID controller adjusts the control variable, such as motor speed, in a feedback loop to minimise the difference between the desired setpoint and the actual value of the process variable. This achieves precise and stable control of the system.

Technidrive’s system uses the VSD control to adjust the motor speed as needed to regulate material flow rates. Radar sensors are deployed to detect specific material levels in the plant. The system then collects data on the electric current drawn by the crushers during their operation. This information is then used to create a PID loop.

The PID loop continuously analyses feedback from sensors to automatically adjust feeder speeds, maintaining optimal material flow rates throughout the operation. Maintaining the optimal level of material in the crusher is essential, as overfilling can lead to inefficiencies, increased power usage and reduced throughput.

The radar sensors effectively grant the plant its own decision-making capabilities regarding material requirements for efficient operation. If material levels decrease, the system automatically speeds up the feeder and vice versa.

While we still marvel at the engineering of the ancient Egyptians constructing the Great Pyramids, we can draw parallels to the modern-day quarrying industry. The fundamentals remain the same — extracting materials from the earth — but technology has propelled us forward, offering solutions to enhance efficiency and safety.

By embracing automation, such as Technidrive’s innovative feeder control system, quarries can optimise operations, minimise downtime and prioritise worker well-being. Just as the Egyptians carved stone to build wonders, today’s quarrying operations can harness automation to sculpt a more productive and efficient industry.

Visit Technidrive’s website to learn more about its solutions for the quarrying industry.