In 1816, clergyman and engineer Robert Stirling first patented his “air engine” in the hope that it would replace steam boilers in coal mines. Following several engineering setbacks and failures, the Stirling engine soon lost its battle with the internal combustion engine (ICE), failing to become the dominant power system. With climate change becoming a more pressing global problem, now may be the time to embrace this 200-year-old engineering concept. Here Ory Zik, CEO of Qnergy, explores.

Currently, we are fighting a global methane challenge that restricts our climate change mitigation efforts. Methane is the second most abundant anthropogenic greenhouse gas, accounting for about 20% of global emissions. As well as having 84X the global warming potential of CO2 over the first 20 years when released into the atmosphere, scientists estimate that methane emissions cause 25% of global warming today.

The methane challenge is a distributed problem, with emissions coming from thousands of oil and gas sites, agriculture, and landfills. It, therefore, needs a distributed solution, where methane is captured and converted at the source — in the form of generators that turn raw methane into energy.

Although we’ve come to rely on ICEs for many power generation applications, they are poorly equipped for raw methane. Unrefined methane is ‘dirty’ and highly corrosive, which can severely damage ICEs. They can therefore run on refined methane only, and this is where Qnergy’s Stirling engine has an advantage.

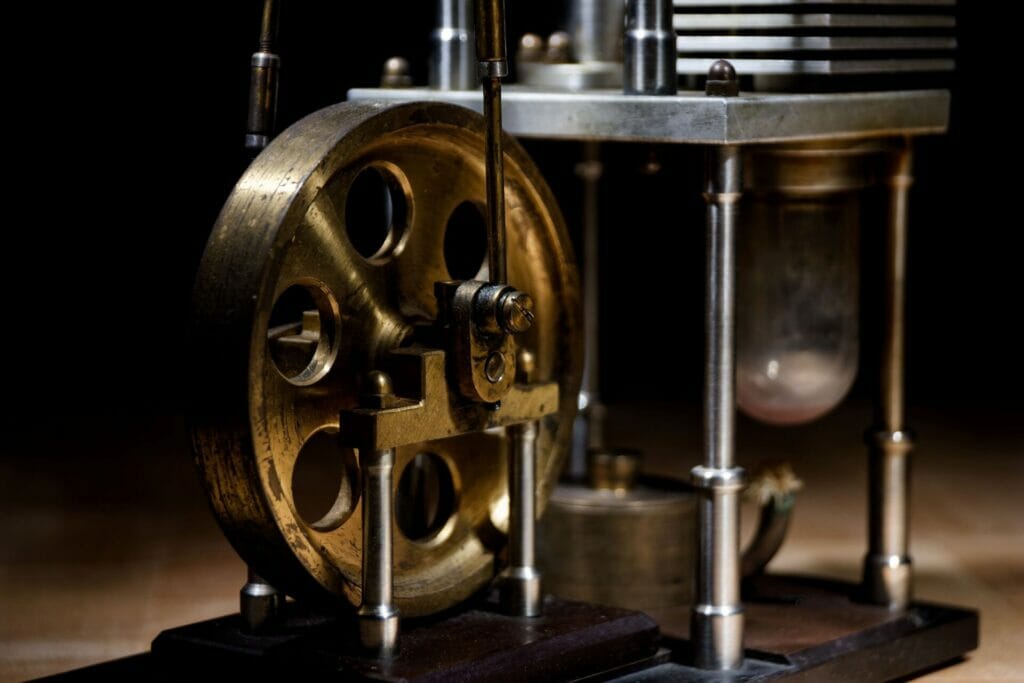

Stirling fundamentals

A Stirling engine is a closed-cycle regenerative heat engine. It works by cyclically compressing and expanding a gaseous fluid at different temperatures to create a net conversion of heat energy to mechanical work.

Whereas ICEs work by having a spark-ignited combustion occur within the engine itself, Stirling engines utilize external combustion to generate electricity. This external combustion characteristic also makes it relatively simple to design a nearly perfect burner for the Stirling engine. If functioning effectively, the burner can operate at the optimal fuel temperature, emitting pollutants in trace amounts only.

The Stirling engine is a true “fuel-flexible” engine. It can operate on a wide range of feedstocks that would otherwise limit an ICE. This includes “dirty” raw methane.

Greater efficiency

Robert Stirling initially proposed an alternative to the steam boiler, which heats water and transports the steam through pipes to drive a turbine. The Stirling engine is built such that waste heat can be readily recuperated and recovered. Consequently, the efficiency of a Stirling engine (defined as the ratio of energy output to energy input) can range from 5 to 95%. On the other hand, typical ICEs waste around 30% of chemical energy in the form of hot exhaust gases. Because of its design, the Stirling engine not only has the capability to capture and convert raw methane into usable electricity, but it can do so efficiently.

200 years after it was first invented, the Stirling engine could provide the answer to the global methane challenge we face. As well as being designed to recapture waste energy, unlike conventional ICEs, the Stirling engine is fuel agnostic and has the potential to convert otherwise-emitted raw methane ‘in-situ’ into reliable electricity.

To find out how Qnergy’s Stirling-powered solutions are helping us tackle the methane challenge, visit its website.

Leave a Reply

You must be logged in to post a comment.