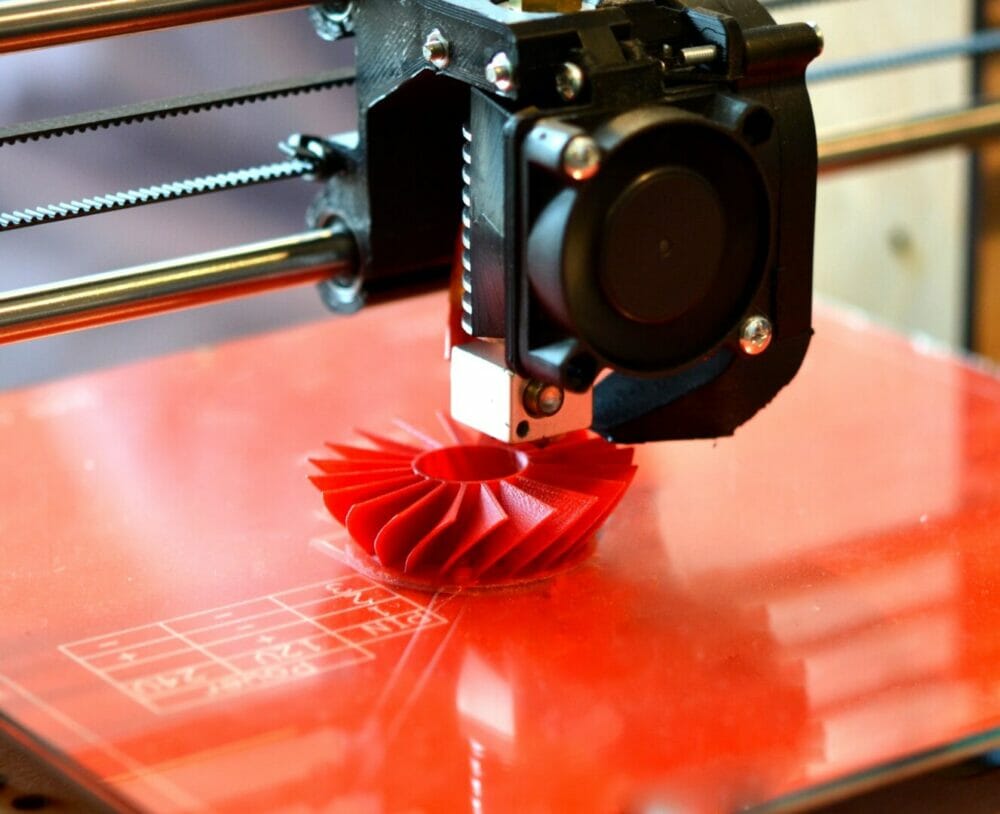

As capabilities and applications advance rapidly, 3D printing is a key element of the manufacturing

process for many industries, often rivalling the traditional manufacturing process for both speed and

cost.

Industries including aerospace, automotive, healthcare are commonly utilising this kind of additive

manufacturing, but as the process becomes more accessible and the long term efficiencies outweigh

the initial costs, an increasing number of businesses are turning to 3D printing.

Although many of these businesses will factor in the costs of the materials and start up costs when

considering investing in a 3D printer, some may be less aware of the upkeep and maintenance

required.

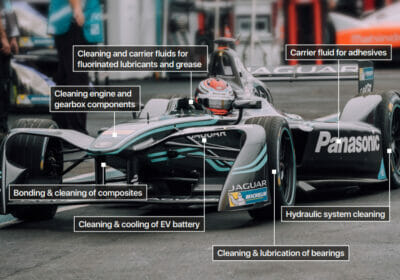

In order to offer a full supply and maintenance package, two companies are working together to

make both the technological and cleaning applications available to customers within Europe.

Fraser Technologies, which provides world-leading cleaning chemistries and equipment solutions,

has been working with Markforged, a US-based manufacturer of industrial 3D printers, materials,

and software.

Markforged produces printers that work with metals like stainless steel, and with composites such as

carbon fibre, fibreglass and Onyx. Fraser Technologies provides expert advice and solutions for

cleaning printed parts.

Graham Fraser, Managing Director of Fraser Technologies, explains: “Any components produced by

a 3D printer require rigorous cleaning. In some cases – depending on the materials used to create

the component – the contamination may not be visible to the naked eye, but they will still need

cleaning prior to assembly. Our solutions offer bespoke chemistries that are applicable to a variety

of component materials to ensure all cleaning standards are upheld.”

Working closely with customers to understand their challenges, Fraser Technologies provides expert

advice and a wide range of world-leading chemistries and equipment solutions for component

cleaning, electronics soldering, and heat transfer and carrier fluids. It offers an independent range of

new generation products; comprehensive after-sales service; and a commitment to improving

performance, productivity, environmental performance and operator safety.

For information, please click here