It is estimated that 60% of the automotive market in the UK will be electric by 2030, compared to

just 5% at the end of 2020, which certainly sets the bar high. As innovative technology emerges in

this field, new challenges become evident, including lithium ion battery technology, which must deal

with the high heat load generated during charge transfer in this brief time.

With this increased heat, it becomes paramount to improve long-term performance and reduce the

fire risk in the battery packs. The key is developing an efficient thermal management solution that

mitigates fire potential and improves heat transfer.

At Fraser Technologies, we work closely with Chemours, which has developed Opteon™ Speciality

Fluids with performance and environmental sustainability in mind. The Opteon™ product portfolio

includes heat transfer fluids for many different applications and temperatures ranging from -90°C to

250°C. These Opteon™ heat transfer fluids are non-flammable, offer excellent stability and provide

superior heat removal in dielectric applications, with an environmentally friendly footprint.

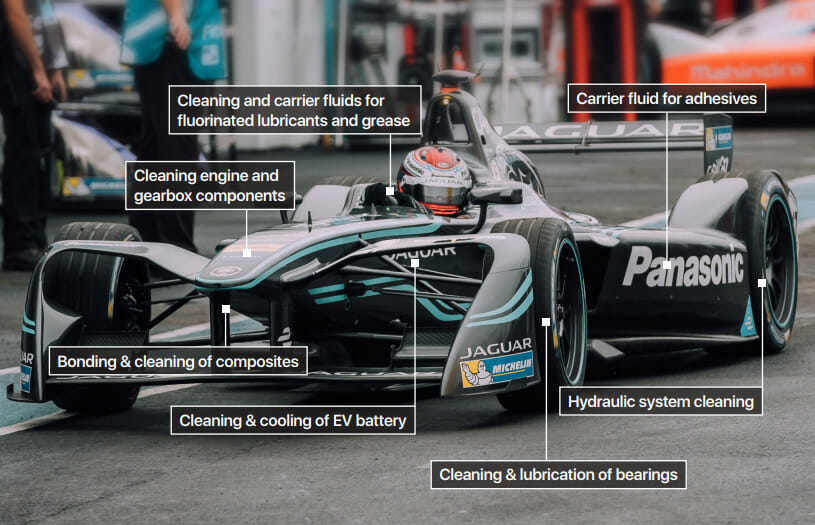

The Opteon™ range also has advanced cleaning potential across the automotive industry, and can be

applied to oil and grease removal, precision cleaning, high solvency defluxing, silicone removal,

vapour degreasing and cold cleaning.

Significant advancements have been made in industrial solvent cleaning, making specialty fluids a

viable, safe and cost-effective option. They use eco-friendly chemistries, and are an effective

alternative to older, hazardous solvents and those containing F-gases that have now been banned or

restricted. And Opteon™ SF80 has a GWP of <2.5, which is one of the lowest GWP figures on the

market for this type of chemistry. Historically, other common F-gas solvents have had GWP figures of

up to 11,000.

The Chemours™ range of safe, environmentally friendly solvents has become widely accepted as

best in class and is approved for use in a large range of standard cleaning systems. If considering a

new solution for oil and grease removal; precision cleaning; high solvency defluxing; silicone

removal; vapour degreasing; or cold cleaning, Fraser Technologies can support the right products to

deliver cleaning requirements.

For more information please click here