Uniqsis report how researchers at Lilly S.A (Madrid, Spain) have developed a novel continuous flow approach for the Wadsworth–Emmons cyclopropanation of alkyl-substituted chiral epoxides into chiral cyclopropane carboxylic acids.

Employing a FlowSyn continuous flow reactor and binary pump in a custom set-up the researchers developed a new flow process which circumvented the risks associated with the high temperature and pressure required, and the highly volatile nature of the epoxide starting material.

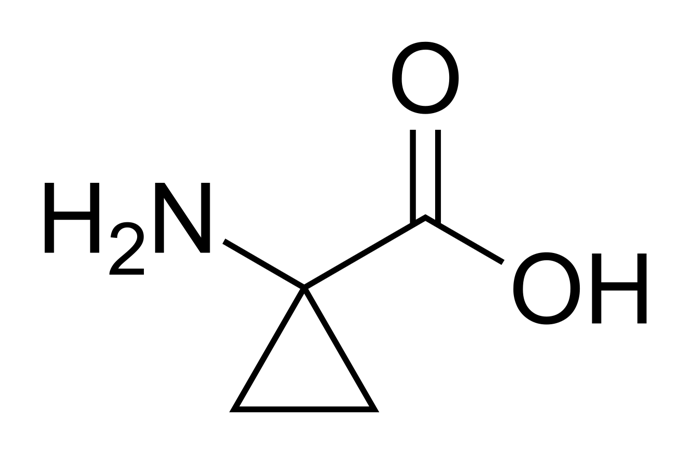

example of a chiral Cyclopropane carboxylic acid

Additionally, the researchers reported that the FlowSyn flow reactor offered increased efficiency, as its reduced headspace contributes to keeping a higher concentration of the low-boiling-point reactants in the liquid phase and thus enhanced reactivity, contrary to the use of sealed vessels in batch.

FlowSyn continuous flow reactor

Using the described approach the researchers coupled their cyclopropane formation process with in-line workup and hydrolysis transformations to yield the desired enantiomerically pure cyclopropane carboxylic acids in good yields up to the 100 g scale. To read this paper in full please visit https://pubs.acs.org/doi/10.1021/acs.oprd.3c00444#

Designed by Uniqsis’s team of experienced flow chemists and engineers – FlowSyn is a fully integrated, easy to use continuous flow reactor for seamless reaction optimisation and scale up from milligrams to 100s of grams. For further information about the FlowSyn continuous flow reactor please visit https://www.uniqsis.com/paFlowSystem.aspx or contact Uniqsis now on +44-1223-942004 / [email protected].

Since 2007, Uniqsis has specialised in the design and supply of mesoscale continuous flow chemistry systems for a wide range of applications in chemical and pharmaceutical research. The company’s aim is to make flow chemistry easily accessible to both novices and experienced users.