Clear market orientation and future-orientated cooperations ensure corporate success

The industrial camera manufacturer IDS Imaging Development Systems GmbH was able to close 2023 successfully and far exceeded industry expectations. As planned, the southern German company achieved growth of 15 per cent compared to the previous year. IDS attributes the positive figures to the development of new products, future-oriented cooperations and good delivery performance thanks to an easing of supply chains. At the same time, the high stock of components means that all products can be delivered within two weeks. By contrast, the VDMA reports a nominal decline in sales of 11 per cent for German manufacturers of machine vision components in the first three quarters of 2023, with a sharp drop in incoming orders.

The Obersulm-based company performs well in a sector comparison. Sales in the DACH region in particular have developed at an above-average rate. IDS sees even greater potential in the US and Asian markets following the turbulence caused by the chip crisis. The aim here is to generate further market share in 2024. The development and introduction of new products should make a decisive contribution to this.

The new IDS management (from left to right): Alexander Lewinsky, Jan Hartmann und Dr Michael Berger

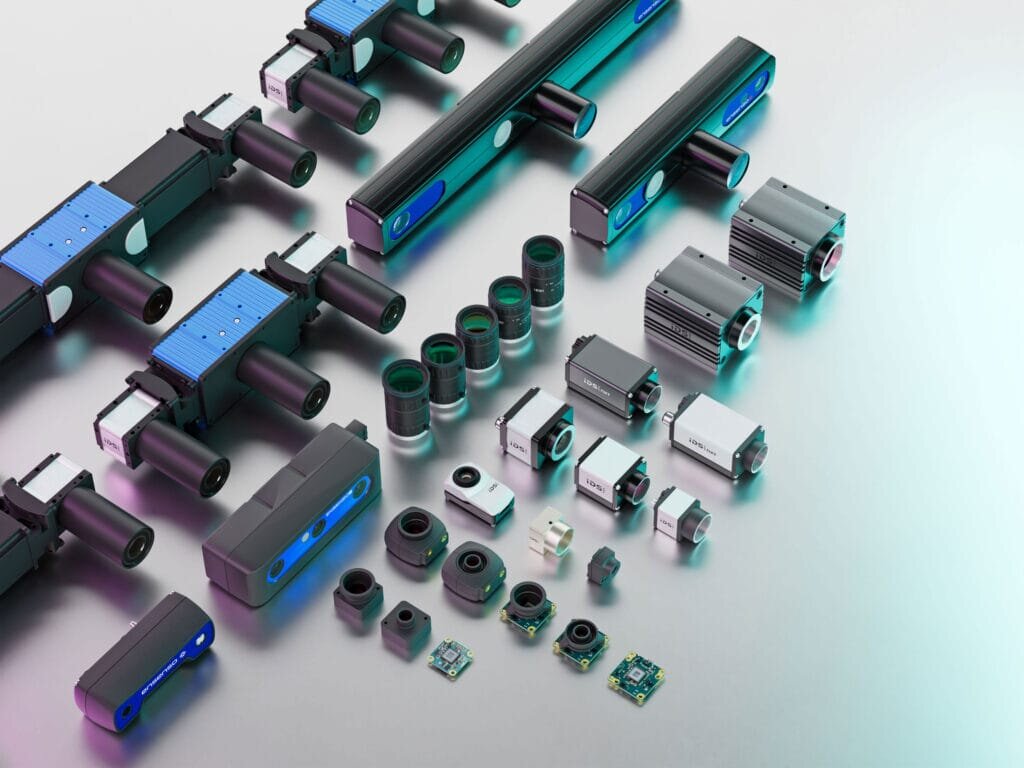

Thus, the Ensenso C was already placed in the fast-growing 3D segment last year. More cameras are to follow. Numerous model enhancements are also planned for the uEye+ 2D camera families, e.g. through the integration of new sensors. “This gives our customers even more choice – from the entry-level range right up to the 10GigE camera series. At the same time, we will continuously improve our IDS peak SDK. To this end, there will be several free software updates over the course of 2024,” explains IDS Managing Partner Jan Hartmann. The IDS NXT platform in the AI segment is also to be extended with the introduction of new models. At the same time, there are plans to expand the capabilities of the IDS NXT malibu – the first industrial camera with result overlay in the video live stream. The latter is made possible by the integration of an Ambarella SoC (System-on-Chip). This and the sales partnership with the Fraunhofer spin-off DENKweit GmbH in relation to their AI-based image analysis are accelerating the development of future technologies. Since the beginning of the year, the company has also been a member of the Innovation Park Artificial Intelligence (IPAI), an innovation-promoting ecosystem that is being created in nearby Heilbronn, Germany.

The family-owned company is also well positioned at management level. At the turn of the year, founder and partner Jürgen Hartmann handed over the management of the operational business and will in future act as Chief Innovation Manager in the family business, providing advice in the areas of technology and innovation. With the entry of Dr Michael Berger into the IDS top trio, the generational transition of the Obersulm-based image processing specialist has thus been successfully completed. Growing together, inspiring worldwide – that is his motto: “We want to anticipate customer wishes with innovative, high-quality industrial camera solutions. That is our core competence and that is how I got to know IDS: innovative and customer-orientated. The fact that our development is located at the main site in Obersulm is of course an absolute advantage for us.”

IDS Imaging Development Systems GmbH is planning numerous model additions for the current year

Ensuring product quality through high in-house production depth

Firmly rooted in the region, IDS regularly invests in the future of the development and production site in Obersulm, Germany. “We guarantee our high product quality “Made in Germany” through an exceptionally high in-house production depth. Regular investments in high-end specialised machinery for internal production and quality assurance ensure this,” confirms Managing Director Alexander Lewinsky. Most recently, a proprietary EMC measuring cabin was built on the company premises. Thus, the electromagnetic compatibility of new developments can be tested in-house in future. This independence from external test laboratories may also shorten development cycles.

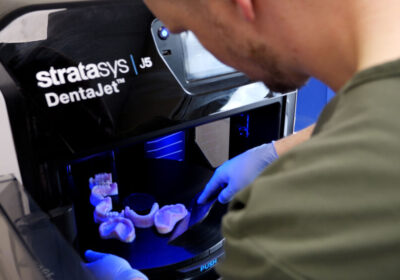

Shortening valuable development time is also promised by the in-house B2B marketplace visionpier. The solution packages that are provided combine hardware, software and seamless integration into existing processes. This gives companies low-threshold access to pioneering technologies. “Thanks to visionpier, we are experiencing growing demand for image processing solutions from various industries and company sizes,” explains Sigrid Rögner, Head of Business Innovation and Ecosystem at IDS. There are currently over 120 solutions on the marketplace that can be customised to meet individual challenges. In 2024, the focus will be on even greater user-friendliness and an expansion of the offering.

Overall, the company focuses on a clear market orientation with products that emphasise customer benefits. At the same time, it always keeps an eye on the issue of sustainability. As a pioneer among the fully climate-compensated companies in the industry, packaging materials, for example, are to be scrutinised more closely in addition to a further reduction in CO2 emissions at the Obersulm site.

www.ids-imaging.com