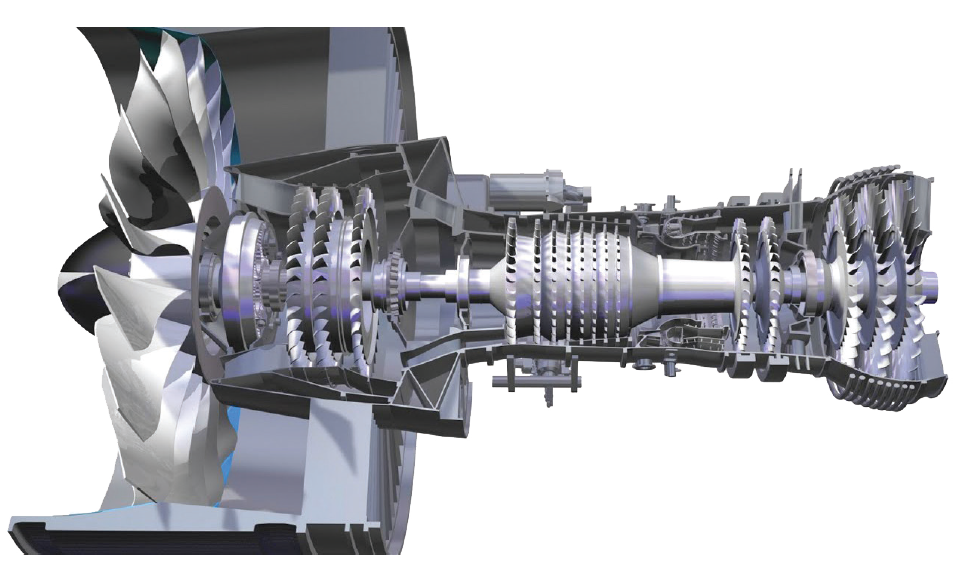

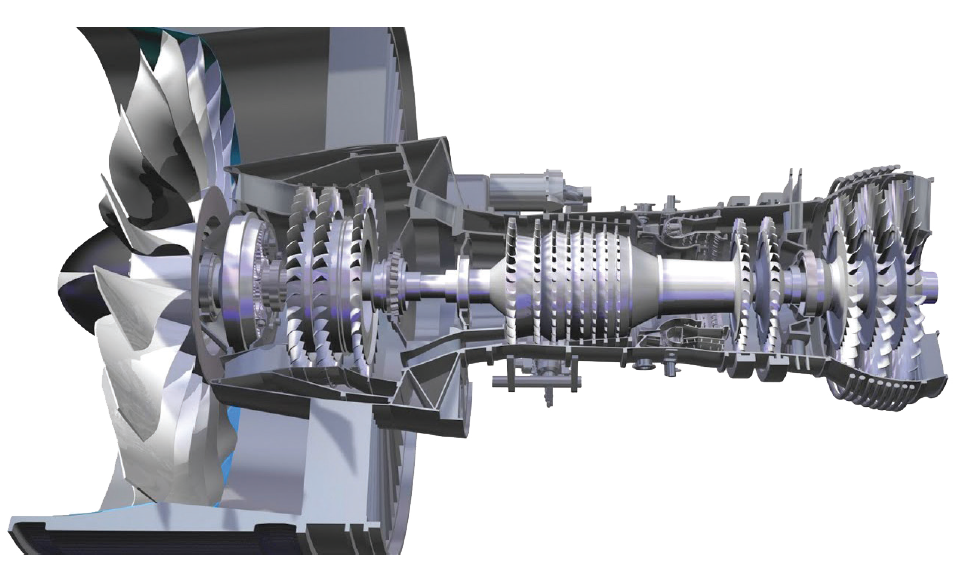

Kitov.ai‘s Kitov-CorePlus, adopted by BSEL (Bet Shemesh Engines), employs machine learning, AI, and 3D vision for automated defect detection in complex environments such as Disc inspection in aerospace. This adaptable, ready-to-use system utilizes a robot-mounted camera with multi-lighting for comprehensive inspection, eliminating fixed cameras and part rotation. The Kitov Smart Planner automates inspection plan and image acquisition using CAD or 3D scans, intuitively learning optimal inspection strategies.

Software combines traditional machine vision, semantic detectors, and deep learning to identify and classify flaws, continuously improving accuracy. It discerns parts by color, geometry, and material, with deep learning identifying abstract attributes. Training on good/bad part images enables the AI to learn and refine defect analysis, minimizing false positives by differentiating defect types.

BSEL experienced outstanding results with Kitov-CorePlus, achieving high accuracy on reflective parts, consistent inspections, and rapid inspection plan creation. Its 3D vision enables comprehensive defect recording and analysis for AI-driven continuous improvement. BSEL reduced disc inspection time from one hour to 12 minutes, enhancing customer confidence and enabling business growth. While human inspectors address manufacturing issues, Kitov-CorePlus automates the core inspection process.

Read the full story at https://tinyurl.com/ykaybjt2

Kitov.ai products are available in the UK and Ireland from Optimax