Yamazaki Mazak is set to host the ‘ultimate showcase’ of manufacturing solutions at its upcoming Mazak Manufacturing Event, held on 20-22 May at the company’s European Technology Centre and Manufacturing Plant in Worcester.

The event will feature 18 different high-productivity manufacturing solutions. Combining the very latest in 2D fiber laser processing, tube cutting and automation, alongside advanced Multi-Tasking and compact 5-axis machining centres, the event is a must-attend for UK manufacturers looking to unlock new levels of productivity and profitability within their own organisation.

Among the machine highlights on display will be the powerful 15 kW variant of Mazak’s OPTIPLEX 3015 NEO 2D laser processing machine. Offering high mechanical rigidity and unwavering reliability, the machine benefits from a series of Intelligent Functions to enhance efficiency, reduce set-up time and optimise productivity.

It will be joined by a second laser processing machine demonstrating Mazak’s expertise in the cutting of small diameter tube and pipe material: the FT-150 NEO. Featuring a unique U-axis control for the high-speed, high-precision cutting of tubes up to ø152 mm, it offers the potential for automatic material loading, cutting, drilling and unloading from just one machine.

Among the 16 different machine tools also on display, and demonstrating the breadth of Mazak’s portfolio will be the INTEGREX e-670H – an advanced Multi-Tasking machine for turning and milling large workpieces in a single set-up – and the highly competitive, compact CV5-500 5-axis machining centre in live-cutting action.

The latest in Mazak’s NEO series range of high-performance machines will also be live-cutting throughout the event. These include the two NEO lasers, alongside two additional NEO machines from Mazak’s machine tool portfolio – the HCN-500 NEO and the VARIAXIS i-700 NEO – that excel in delivering exceptional productivity and precision, while also providing best-in-class environmental performance.

Crucially, the three-day event will offer visitors a chance to experience the latest investments to Mazak’s Sheet Metal Department, which now acts as a real-life showroom for the company’s laser and automation systems.

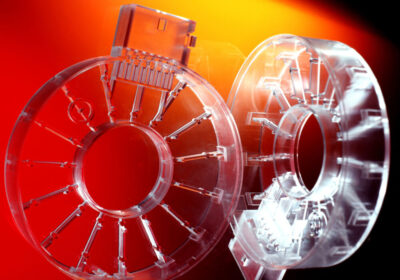

Central to the upgrade has been the introduction of two automated 6 kW OPTIPLEX 3015 NEO 2D fiber laser machines, which are used to cut a variety of components for its range of UK-made machine tools.

The two lasers are tended by a Mazak CSTD Double Tower system to feed the sheet metal and a robotised Mazak Smart Manufacturing Cell for parts sorting. Not only has the investment already reduced overall power consumption by 67%, but also the enhanced automation has helped to cut machine waiting times and further improve productivity through unmanned operations.

Guided tours of the Sheet Metal Department and wider European Manufacturing Plant will be available to all visitors, alongside a series of technical demonstrations from Mazak and several of its key technology partners.

Alan Mucklow, Managing Director UK & National Distributors at Yamazaki Mazak, said: “While UK manufacturers are facing several different challenges, the key to remaining competitive is to continually invest in solutions which can provide a tangible improvement in productivity.

“We have seen the impact first-hand at our European Manufacturing Plant and we look forward to sharing these insights, along with the ultimate showcase of high-productivity Mazak solutions, all under one roof at our upcoming event.”

You can find out more about the Mazak Manufacturing Event and enter your registration details at: https://discover.mazak.com/eu-open-house-mt.