Brett Saddoris, Technical Marketing Manager, Accumold

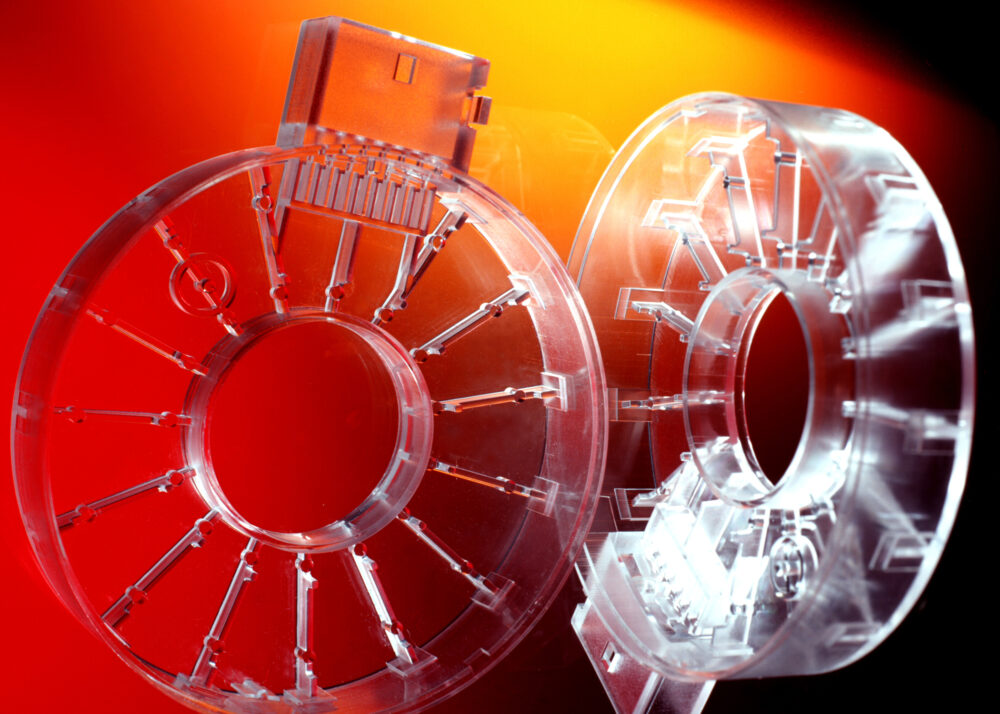

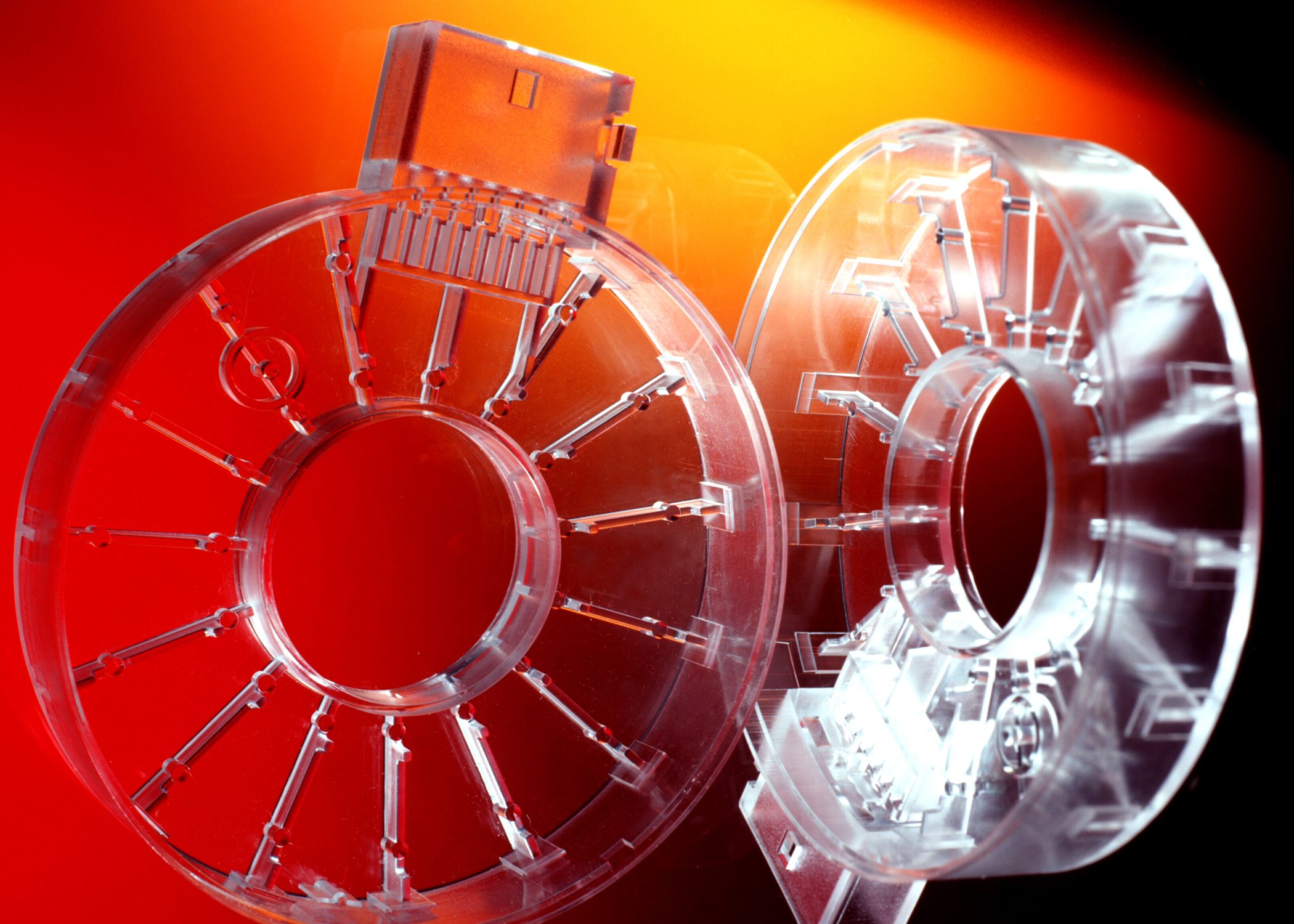

Micro molding is one of the most advanced and challenging disciplines within precision manufacturing. As industries such as medical, electronics, automotive, and optics demand increasingly smaller, more intricate components, the pressure on micro molders to deliver high-precision, high-quality parts has never been greater. Quality is not just a desirable attribute in micro molding, it is an absolute necessity.

This article explores the fundamental need for an unwavering focus on quality in micro molding and highlights key perspectives from Accumold, a leader in micro molding innovation. The article aims to show manufacturers, engineers, and procurement professionals the importance of prioritizing quality when selecting a micro molding specialist.

The Challenge of Miniaturization

As micro molding technology advances, parts are becoming increasingly smaller, often with features that are difficult to see with the naked eye. According to Cara Bloom, Senior Quality Engineer at Accumold, “as parts get smaller, generally the tolerances get smaller as well.” This presents a unique challenge, as maintaining consistent quality at such minuscule scales requires extreme precision. The margin for error is practically non-existent.

Micro molded components are used in applications where failure is not an option. Whether it is a microfluidic medical device, a micro-optical lens, or a high-frequency RF component, even the slightest deviation from the intended design can compromise performance, functionality, or even safety. This means manufacturers must invest in sophisticated metrology and validation processes to ensure that every part meets exact specifications.

Quality as an Integral Part of the Process

At Accumold, quality is not an afterthought, it is embedded into every stage of production. The company’s vertically integrated approach ensures that validation, metrology, and quality control are seamlessly integrated from the initial design phase through to final production. A key aspect of maintaining quality in micro molding is having the right metrology tools. “We need to have equipment that can handle the precision and accuracy needed by these challenging projects,” says Bloom.

For exacting projects, Accumold utilizes Zygo’s NewView 8300 Optical Profiler, a non-contact white light interferometry system capable of sub-nanometer precision. This technology allows for the measurement of critical features such as lens prescriptions and flatness values, some of which have tolerances as tight as tenths of a micron. Beyond optical metrology, Accumold employs a range of advanced tools, including Optical Gaging Products (OGP) multi-sensor equipment with rotary, touch trigger, laser interferometry, and Zone3 software, which facilitates CAD model-based part evaluation. In addition, Keyence devices with pattern recognition software allow for the inspection of micro parts with minimal fixturing, further enhancing accuracy and efficiency.

Measurement: A Necessary but Often Overlooked Consideration

One of the biggest mistakes companies make when selecting a micro molder is assuming that if a manufacturer can mold a part, they can also measure it effectively. However, micro metrology presents its own unique challenges, if you cannot measure it, you cannot make it.

This highlights the importance of integrating measurement development into the early stages of product development. Accurate and repeatable measurements are essential for process validation, ensuring that molded parts consistently meet design intent. At Accumold, measurement development and Gage Repeatability and Reproducibility (Gage R&R) studies are key components of the company’s quality assurance process. By working closely with customers on design for manufacturability (DFM) and design for micro molding (DfMM), Accumold helps optimize part designs for both moldability and metrology.

Achieving quality in micro molding is far more complex than in traditional injection molding. One major challenge is part size and tolerances. Micro molded parts can be dimensioned in microns, with features that require magnification of 10x or greater to even be visible. Measuring such small parts demands non-contact methods such as laser scanning, white light interferometry, or high-resolution vision systems. Another challenge is part fixturing. Ensuring repeatable and reproducible measurements requires precise fixturing. At Accumold, custom steel or 3D-printed plastic fixtures are designed in-house to securely hold parts during measurement, ensuring accuracy and consistency.

Surface roughness also presents a challenge, especially in applications such as optics and medical devices where surface finish is critical. Traditional tactile measurement tools can alter or damage the surface of delicate micro parts, making non-contact metrology the preferred method. As already mentioned, white light interferometry, for example, allows Accumold to measure surface roughness without compromising part integrity.

Additionally, there is an ongoing discussion regarding in-lab versus in-process metrology. While traditional metrology was often confined to lab environments, modern micro molders increasingly integrate in-process metrology for real-time quality control. Accumold strategically assesses metrology requirements based on part complexity, volume, and tolerance levels to determine whether in-process or lab-based measurement is most appropriate.

![]()

Continuous Improvement and the Future of Micro Molding Quality Assurance

Ensuring consistent quality in micro molding is an ongoing effort. As new metrology technologies emerge, micro molders must continually evaluate and adopt new equipment and methodologies to stay ahead. “We continually evaluate new equipment that may help us improve our measurements, either in efficiency or accuracy, as new metrology equipment enters the market,” Bloom explains. This commitment to continuous improvement ensures that Accumold remains at the forefront of micro molding quality assurance.

Additionally, automation is playing an increasingly vital role in micro metrology. Automated vision inspection (AVI) systems, integrated into molding processes, allow for rapid, repeatable inspections without human intervention. This reduces variability and increases throughput, ensuring that quality control keeps pace with high-volume production demands.

For companies looking to leverage micro molding, the emphasis must always be on quality. It is not enough to select a manufacturer based solely on cost or turnaround time — quality must be the defining factor. When evaluating a potential micro molding partner, it is crucial to assess their metrology capabilities, ensuring they have the necessary equipment and expertise to measure parts accurately. Process validation should also be a key consideration, with quality control integrated throughout the entire manufacturing process.

Collaborating with a micro molder that prioritizes design for manufacturability and metrology optimization ensures that the final components will be both functional and precise. Furthermore, a commitment to continuous improvement and investment in advanced quality control methods are indicators of a reliable and forward-thinking micro molding specialist.

Summary

The fundamental requirement for quality in micro molding cannot be overstated. As parts shrink in size and tolerances tighten, manufacturers must ensure that their chosen micro molding partner has the expertise, technology, and commitment to deliver precision without compromise. By prioritizing metrology, process validation, and continuous improvement, micro molders can ensure that every component meets stringent requirements, reducing risk and enhancing overall product performance. In a world where quality is non-negotiable, choosing a micro molding partner that takes it seriously is the only viable path forward.