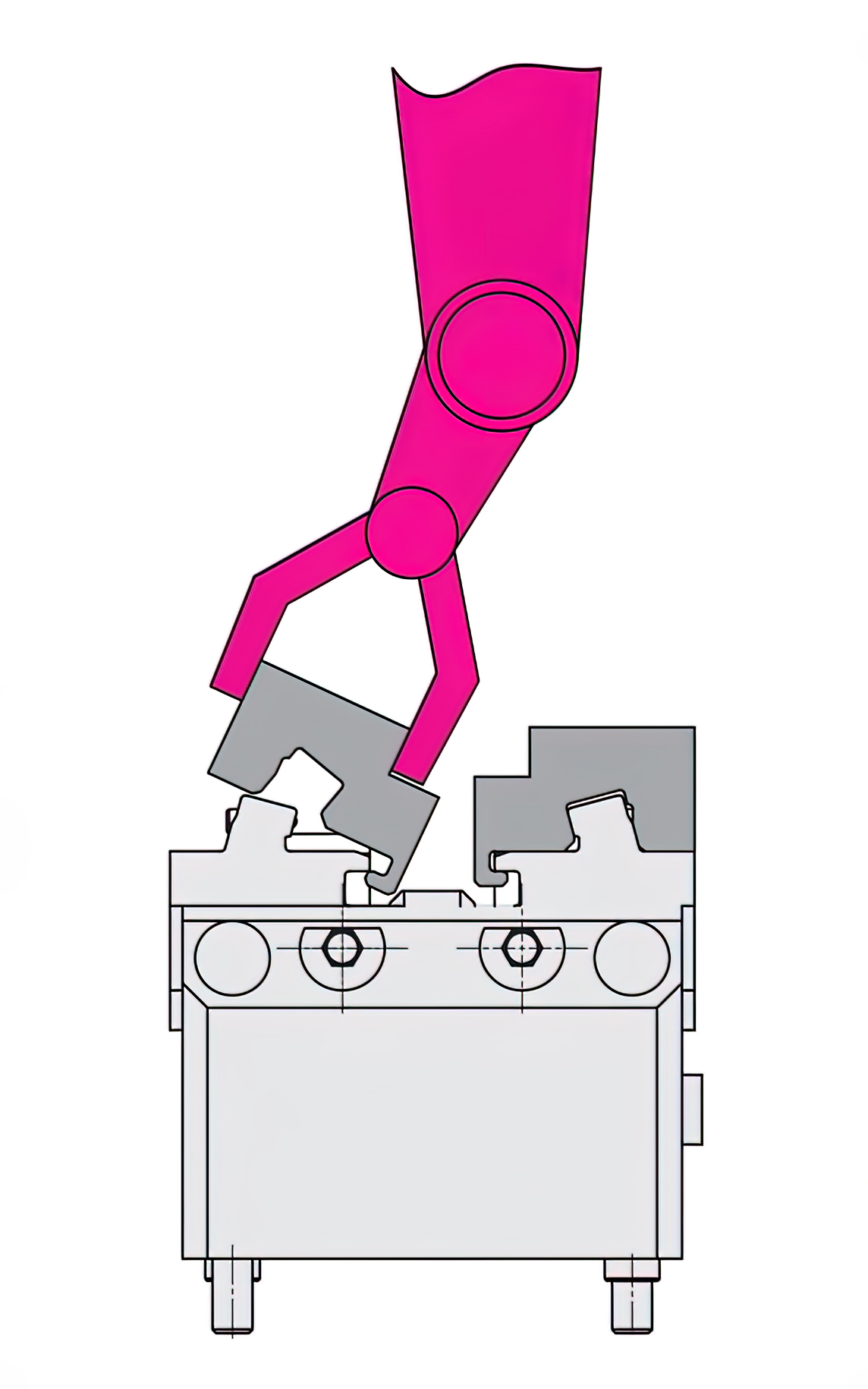

A new range of four double-acting, self-centring (centric) vices of particularly compact design for demanding clamping applications in restricted working areas, often found in milling, drilling, grinding, electric discharge machining and fixture building, has been introduced by Roemheld (UK).

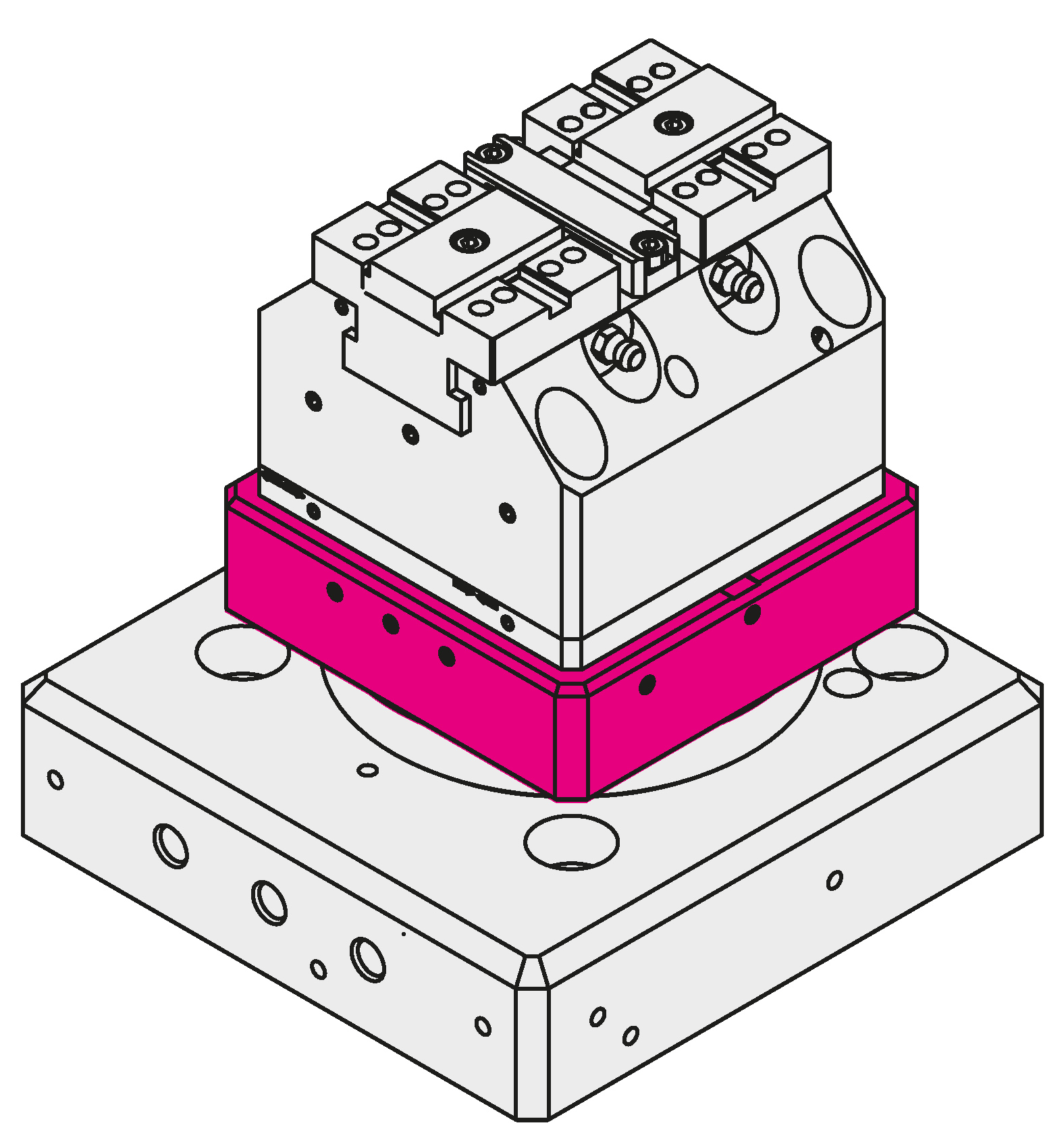

The H 4.400 Power Clamp is available in two sizes of base, 64 or 100 mm square, which is contoured below the jaws to provide good accessibility to all five sides of a clamped component and promote free chip evacuation during machining. Jaw actuation is either hydraulic or pneumatic. The small and large hydraulic versions deliver 4.8 and 20.3 kN of clamping force respectively, while the pneumatic variants are rated at 4.0 kN and 14.0 kN.

The double-acting piston with backlash-free transmission of force to the two base jaws means that all models are suitable for internal or external workholding. The jaws move synchronously and concentrically, enabling precise workpiece positioning to within 5 microns. The high rigidity of the vices and their hardened surfaces ensure long-term wear resistance, minimising the need for maintenance.

A standard feature is a connection for positive air pressure to protect against ingress of liquids and dirt particles. A comprehensive range of options is offered, including various quick-change jaws and mounting options, monitoring of clamping stroke and part position, zero-point adaptation, sensors for process monitoring, a port for centralised lubrication and RFID chip recognition for tracking and data management. These and other accessories allow extensive customisation possibilities and seamless integration into diverse production environments, including those involving automated part handling.