~ Practical approaches to improve installation, services and maintenance ~

According to McKinsey & Company, many companies still face rising maintenance costs, with only “51 per cent of maintenance activity” focused on prevention, leading to increased operational disruptions. This challenge is especially relevant in material handling, where maintenance delays can cause production bottlenecks and safety risks. Effective maintenance is essential not only for productivity but also for operational resilience. Here, Stephen Harding, managing director at Gough Engineering, explores practical steps that can address common maintenance and installation challenges in material handling environments.

In material handling, reactive maintenance — addressing issues only after equipment fails — continues to drive up costs. This approach, used by nearly half of the companies surveyed, can lead to sudden and complete production line stoppages, costing both time and money. Proactive maintenance, on the other hand, leverages regular, scheduled upkeep to identify and address potential issues before they become major problems. This shift to preventive strategies requires thoughtful planning, and often an investment in both personnel and technology to avoid costly breakdowns and therefore maintain a steady workflow.

The industry also faces a skilled labour shortage, reports McKinsey & Company, with “73 per cent of respondents” reporting difficulty in finding qualified maintenance technicians. This shortage further strains operations, as fewer technicians are available to perform preventive and reactive maintenance, leading to prolonged downtime.

Training existing personnel with diagnostic reporting capabilities or technologies can help address this gap by empowering teams to troubleshoot common issues and extend the lifespan of equipment. Indeed, providing operators with good technical training fosters a more self-reliant workforce, strengthens immediate response capabilities and maintains equipment reliability over the long term.

Foundation is prevention

With many companies adopting maintenance transformation programmes, the industry is increasingly recognising that ‘the foundation is prevention.’ Transitioning to preventive maintenance minimises unexpected failures and enhances equipment lifespan.

One effective strategy is reliability-centred maintenance, where companies develop maintenance protocols based on each asset’s critical role in operations. Predictive maintenance tools, such as sensors for monitoring temperature, pressure or vibrations, can also support reliability-centred maintenance by identifying early signs of wear or misalignment before they affect production.

These technologies should also be reinforced with human expertise. Fortunately, expert advice is available for companies that are uncertain about performance issues with previously supplied screening or material transfer systems.

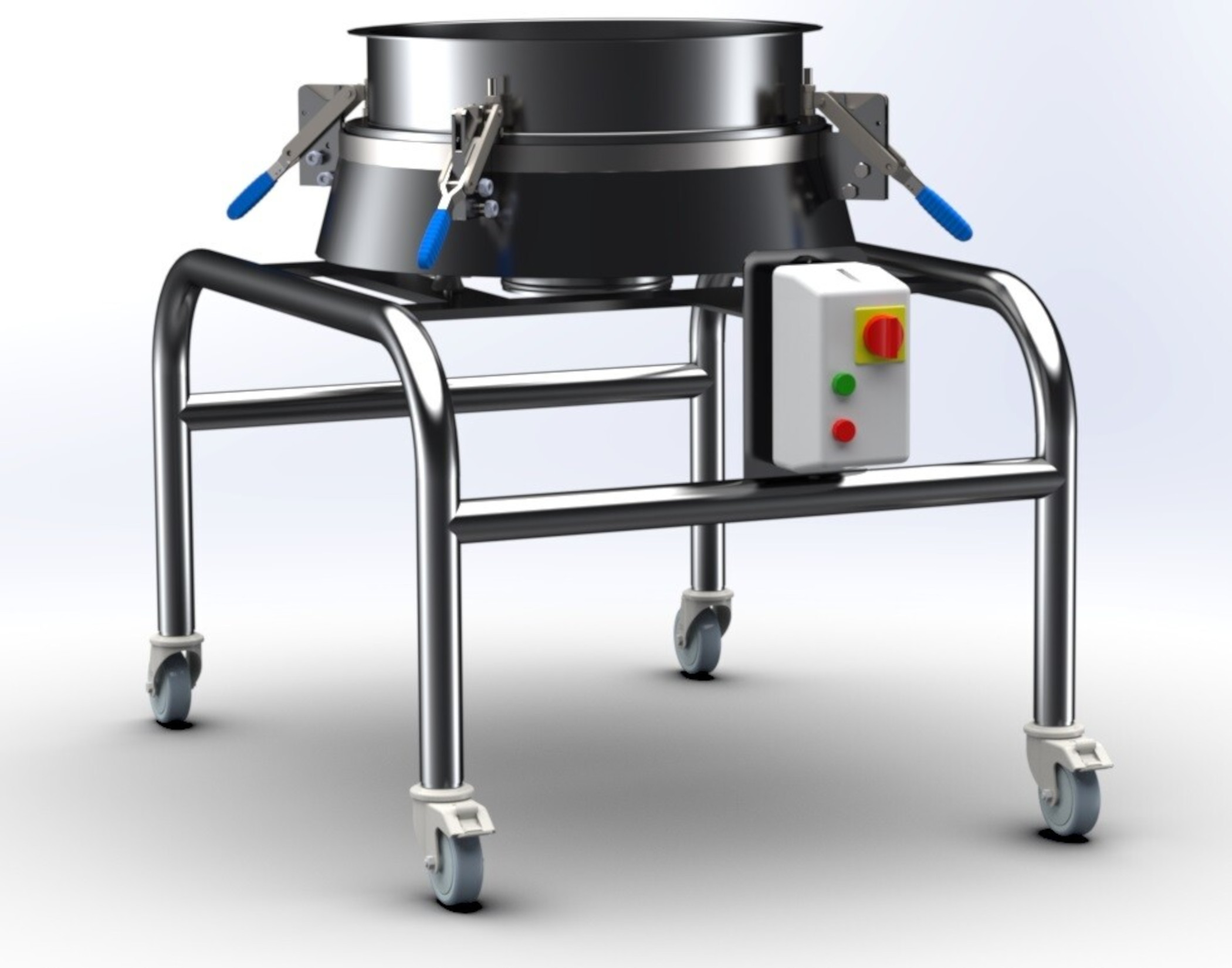

The Gough Batch Sieve is designed for efficient separation screening and reliable performance in demanding environments.

With extensive experience across various industries, Gough Engineering provides valuable knowledge and resources to help manufacturers resolve issues and get back on track. That includes online equipment checklists that are available for download on its website. These cover key areas for sieving with the Gough Batch Sieve, separation screening with the Gough Vibrecon® or Vibraflo® machines, and daily and weekly checks for Gough Swinglink® Bucket Elevators.

Gough Engineering guides its customers through maintenance scheduling as part of its comprehensive parts and service support. Experienced installation and servicing engineers assist with preventative maintenance, part and component exchanges, as well as full health checks to optimise production uptime. These steps help to ensure that material handling machines deliver consistent performance in high-demand environments, while minimising downtime and reducing the need for frequent repairs.

For instance, when a UK manufacturer of snacks opted for Gough Engineering’s equipment, the transition to a new system was strategically managed to ensure minimal disruption to production, which helped the company avoid further delays and repair costs. The project outcome can underline the value of investing in durable machinery and proactive maintenance — by carefully planning for system upgrades, customers are then able to improve efficiency and reduce costs.

Performing routine checks on material handling equipment is essential for ensuring smooth operation and reducing downtime.

Implementing sustainable maintenance practices

Transitioning to proactive maintenance can be challenging but is crucial for long-term productivity. For instance, ensuring regular inspections, incorporating training for operational staff and planning for periodic upgrades can help extend asset life while avoiding unexpected breakdowns.

Maintenance schedules based on asset importance and potential failure points can keep operations running smoothly, ensuring that high-impact equipment receives priority attention. Additionally, establishing a partnership with equipment providers can offer both strategic support and technical expertise, helping to manage complex maintenance issues.

Directly tackling these maintenance challenges allows material handling operations to boost productivity, cut costs and build a more resilient foundation for future growth. Correct proactive maintenance will increase machinery life cycles, thereby saving on new investment.

To learn more about how Gough Engineering can support installation, services and maintenance in material handling, visit its website today.