FPT Industrial, the Iveco Group Brand dedicated to the design, production, and sale of powertrains and solutions for on- and off-road vehicles, as well as marine and power generation applications, will be exhibiting at bauma CHINA, the international trade fair for construction machinery, building material machines, mining machines and construction vehicles. From 26 to 29 November, at the Shanghai New International Expo Centre (Booth N5.110), the Brand will be showcasing its latest offerings for off-road applications in both internal combustion and ePowertrain variants.

Attendees of the leading trade fair for the entire construction and building-material machine industry in China and throughout Asia will be able to discover FPT Industrial’s vision of the future of construction vehicles and machinery, focused on providing ever-more efficient, reliable and sustainable products. At its core, the company’s multi-energy approach – based on continuing to invest in internal combustion engine development, while positioning itself as a zero-emission solution provider – will allow it to meet all the needs of the construction industry, while fully complying with Stage V and China IV emission standards.

INTERNAL COMBUSTION ENGINE (ICE) LINE-UP – FULL RANGE SOLUTIONS TO MEET ALL THE POWER NEEDS OF THE CONSTRUCTION INDUSTRY

FPT Industrial is continuing to invest in internal combustion engines, considering them central

in the Brand’s decarbonization program. FPT Industrial’s comprehensive offering features engine families with power ranges from 40 to 670 kW and displacements from 2.8 to 20 liters. This wide horsepower range enables a huge number of applications: they can be fitted to excavators, wheel loaders, skid steer loaders, graders, dozers, forklifts, snowplows, and cranes. These engines can also be used as a secondary power source. All products, for unregulated markets up to Stage V, are designed for maximum flexibility and can be customized on request.

F28 Diesel Stage V – Exceptionally compact, highly modular, highly efficient

The F28 is a single-engine solution perfect for both space and performance–driven applications thanks to enhanced output with extremely compact packaging, and delivering 3.4 l performance with a displacement of just 2 l. The F28’s performance is best-in-class in the 55 kW category, thanks to high low-end torque (300 Nm @ 1,000 rpm, 23% higher than the competitor average) and max torque avg. (375 Nm @1400 rpm, 26% higher than competitors). Available for both construction and agricultural applications, its versatile design makes it ideal for equipment in the rental industry, such as aerial lifts, telehandlers, pumps, welders, chippers, and trenchers.

F28 is designed to be multi-power and features a modular architecture. In addition to the diesel version, which is already available on the market, there are also versions developed to run on Natural Gas and suitable for hybrid applications, providing the best performance in all working conditions and ensuring maximum installation flexibility. Single-side serviceability and a 600-hour oil change interval result in great ease of maintenance and reduced operating costs. The F28 can be customized on request, offering a wide range of options including flywheel, housings, oil pans, and filters. The particularly compact after-treatment solution comes with common packaging to meet both Stage V and Tier 4 Final standards.

F36 Diesel Stage V – High performance with compact packaging for light and midrange applications

The F36 represents the compact and flexible solution for light and midrange applications, delivering high performance with low operating costs and reduced fuel consumption. All these qualities are fundamental for construction equipment applications in this size. The optimized design of the turbochargers and pistons ensures excellent power and torque density – 15% higher than the competitor average – for applications above 56 kW, and 14% higher power (up to 105 kW) and 20% more torque (up to 600 Nm) compared to Stage IV.

Compliance with Stage V emissions requirements is guaranteed by FPT Industrial’s Compact HI-eSCR2. This ATS system does not require layout changes and is maintenance free, with no need to replace filters or clean components over its entire lifecycle, optimizing sustainability, efficiency, uptime and ease-of-use. This all-in-one solution includes a Diesel Oxidation Catalyst (DOC), a Diesel Particulate Filter (DPF) with optimized technology to ensure high PM removal even at low operating temperatures, and the Selective Catalytic Reduction (SCR) system.

Operating costs are minimized with 600-hour oil-change intervals, efficient low-rate EGR combustion (<10%), and maintenance free ATS, which also maximizes vehicle uptime. The single-side serviceability layout allows for fast and easy maintenance operations.

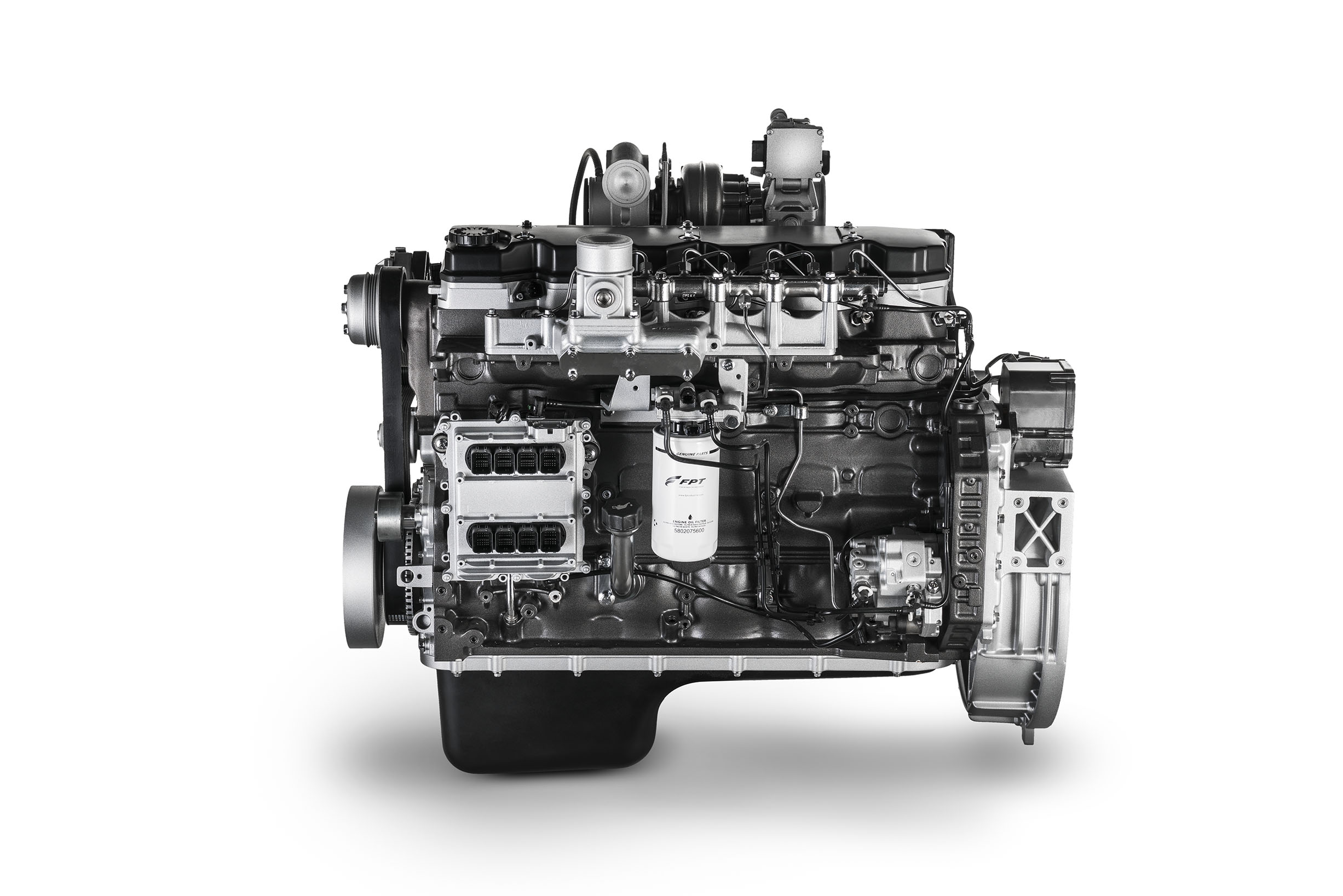

N67 Diesel Stage V – Excellence’s boost to productivity

N67 Diesel Stage V – Excellence’s boost to productivity

The NEF series is the best example of FPT Industrial’s technological excellence. Since 2001 over two million of these engines have been produced for a range of applications, including construction equipment. NEF engines boast best-in-class power and torque performance (up to +14% vs. competitors average) and reliability, standing out for their robustness and durability.

In its continuous commitment to provide leading products and improved solutions, FPT Industrial indtroduced the new Stage V NEF Series, taking a further step towards higher productivity. While maintaining the same engine dimensions and layout of previous versions, the cylinder head, pistons and turbochargers have been redesigned for increased performance. For the N67, the 6.7 liter six-cylinder model, performance has been increased by 9%.

Thanks to its EGR-free architecture, cutting-edge Common Rail injection, turbocharger and redesigned hardware, the N67 ensures optimal combustion efficiency. This means low fuel consumption and high power density. The renewed engine hardware also allows for reduced total cost of ownership (TCO), with best-in-class service intervals of up to 600 hours, thanks to new high-capacity filters with clogging sensor, optimized fuel efficiency with EGR-free combustion (which also maximizes power, torque and transient response), and maintenance-free aftertreatment for low running costs over the entire service life.

CURSOR 9 Stage V – Top performance for heavy-duty operations

The CURSOR family is FPT Industrial’s engine series developed for the most demanding heavy-duty off-road requirements, designed to provide high performance, robustness, and reliability for applications with highly intensive missions, ensuring low operating costs and maximum productivity. First launched in 1998, the CURSOR range has undergone continuous improvements to keep pace with growing customer requirements in terms of performance and efficiency, while complying with stricter emission regulations and always offering innovative technical content, such as variable-geometry turbochargers, high-pressure Common Rail injection, new materials, and breakthrough after-treatment technologies.

Excellent performance – with up to +7% power density higher than the market average for the 9 l range – high torque availability, for fast load response and maximized in-field productivity, and outstanding power density make the CURSOR 9 the perfect choice for a wide range of operations. Not just excellence, but efficiency: the EGR-free combustion provides high system efficiency and low fluid consumption, while the patented and maintenance-free HI-eSCR2 solution keeps running costs low.

ePOWERTRAIN LINE-UP – LEAPS AND BOUNDS TOWARDS A ZERO-EMISSION INDUSTRY

ePOWERTRAIN LINE-UP – LEAPS AND BOUNDS TOWARDS A ZERO-EMISSION INDUSTRY

At bauma CHINA 2024, FPT Industrial will be presenting a glimpse of its ePowertrain line-up, whose development started on in 2018 with the creation of a dedicated department. In response to customer needs and requirements, FPT Industrial’s objective is not only to supply individual system components, but to serve as an ePowertrain systems integrator, guiding its customers through the process of selecting, designing, and correctly sizing complete systems for electric solutions.

eAX 375-R – A high-performance and efficient solution for medium- and heavy-duty applications

The eAX 375-R is suitable for medium and heavy-duty 4×2 and 6×2 vehicles up to 29 tonnes GVW, and 6×4 vehicles up to 49 tonnes GCW, as well as for intercity and coach applications. The design allows this electric axle to be scalable, and makes it extremely adaptable to a wide range of powertrain requirements, supporting everyday customer needs.

Thanks to its multi-speed design, the eAX 375-R delivers high performance and outstanding efficiency. Up to 30,000 Nm torque at the wheels, and service life of up to 1.6 million km (mission-dependent) ensure sustainability and deliver excellent uptime performance.