~ Choosing the right communication protocol for sensor-based applications ~

In an age of growing connectivity, the choice between wired and wireless communication can be the deciding factor in the performance and efficiency of a system. Here, Ross Turnbull, Director of Business Development and Product Engineering at ASIC specialist Swindon Silicon Systems, offers his advice on optimal sensor communication, no matter the environment.

The debate between wired and wireless communication isn’t just about technology preferences — it’s about understanding the specific demands of your application. Each approach offers distinct advantages, and choosing the right one depends on several critical factors.

Wired communication

Wired communication uses physical connections, such as cables, to transfer sensor data. This method is known for providing stable, high-speed and interference-free transmission. It is particularly ideal for industrial settings where machinery operates in harsh conditions — often battling high vibrations, extreme temperatures and noisy electromagnetic environments — wired solutions offer unrivalled stability and reliability.

Additionally, wired communication often results in faster, real-time data transmission. In applications like robotics, where instantaneous feedback is critical to operation, a wired connection provides the speed and accuracy needed to maintain performance without the risk of data loss or delay.

Installation is one of the greatest considerations with wireless communication, as it can hamper their scalability. Once sensors are physically wired, any modifications, upgrades or expansions to the system may require rerouting cables. This lack of flexibility can be a major constraint, especially in dynamic environments where sensor layouts or system configurations need to be frequently updated or scaled.

Going wireless

Wireless technology, on the other hand, offers the kind of flexibility that is becoming increasingly desirable in sectors such as healthcare, consumer electronics and remote industrial monitoring. The absence of physical wiring means that sensors can be deployed in more compact designs, or in locations where traditional wiring would be impractical.

Wireless communication protocols offer a wide range of options based on the application’s needs. For instance, Wi-Fi can be used for high-bandwidth data transfer over longer distances, while Bluetooth is suitable for low-power, short-range communication. The selection of the appropriate protocol ensures that the sensor system is optimised for its specific environment and data transmission needs.

However, those selecting a wireless protocol must consider the potential for interference and power limitations. Wireless systems are more susceptible to interference from other devices, which can lead to unreliable data transmission or even signal loss. Additionally, wireless sensors often rely on battery power, and frequent data transmission can quickly drain these batteries.

Choose custom

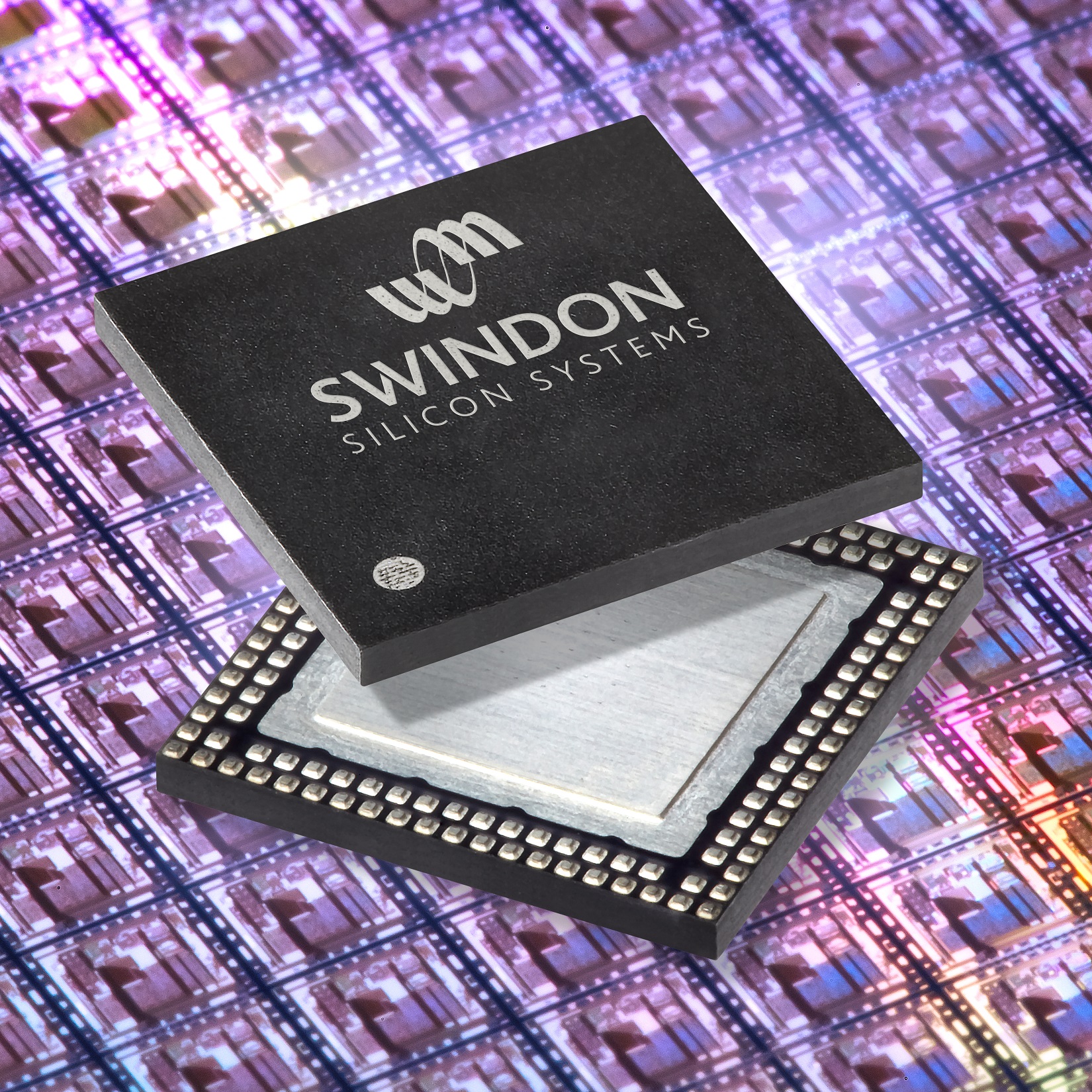

Application-Specific Integrated Circuits (ASICs) provide significant advantages over off-the-shelf Integrated Circuits (ICs) when optimising both wired and wireless communication in sensor systems.

For wired communication, ASICs can be tailored to minimise power consumption while delivering high-speed data transfer, particularly in industrial environments. ASICs are specifically engineered to withstand harsh conditions such as extreme temperatures or electromagnetic interference, ensuring stable and reliable connections where off-the-shelf ICs may fail.

For wireless communication, ASICs offer the ability to precisely manage complex protocols while significantly optimising battery life. Off-the-shelf ICs often come with unnecessary features that can drain power, but ASICs are streamlined to include only what’s needed, maximising efficiency. This custom design allows wireless sensors to operate effectively in remote or battery-powered applications, making ASICs the superior choice for delivering tailored solutions that outperform generic ICs in both wired and wireless systems.

Swindon’s experience a diverse range of markets has driven expertise in many different communication protocols, with new solutions being continuously created. The interface required depends on the application and is determined by industry standards and customer requirements. For wireless communication, BLE through to custom ISM band transmitters and receivers can be integrated onto an ASIC or integrated into a multi-chip package depending upon customer requirements and application review.

Likewise, there are many wired analogue and digital communication protocols. Swindon’s extensive IP means that we have the building blocks ready to craft an ASIC for both wired and wireless communication applications, which can greatly speed up the development process while still ensuring a tailored end product.

In a world of increasing connectivity, the choice between wired and wireless communication is critical to system performance. Custom ASICs deliver optimised, efficient solutions tailored to meet the specific demands of any application, ensuring superior performance in both wired and wireless environments.

Want to learn more about sensor interfaces from Swindon Silicon Systems? Head to the website to get in touch with the team for a first, no-obligation discussion on how a custom IC can benefit your product.