Accumold, with over 40 years of experience in micro molding technology, is set to participate at Compamed, taking place in Düsseldorf, Germany, from November 11-14. The company will highlight its expertise in creating extremely small and complex parts for medical device OEMs at Hall 8b, Stand G21.

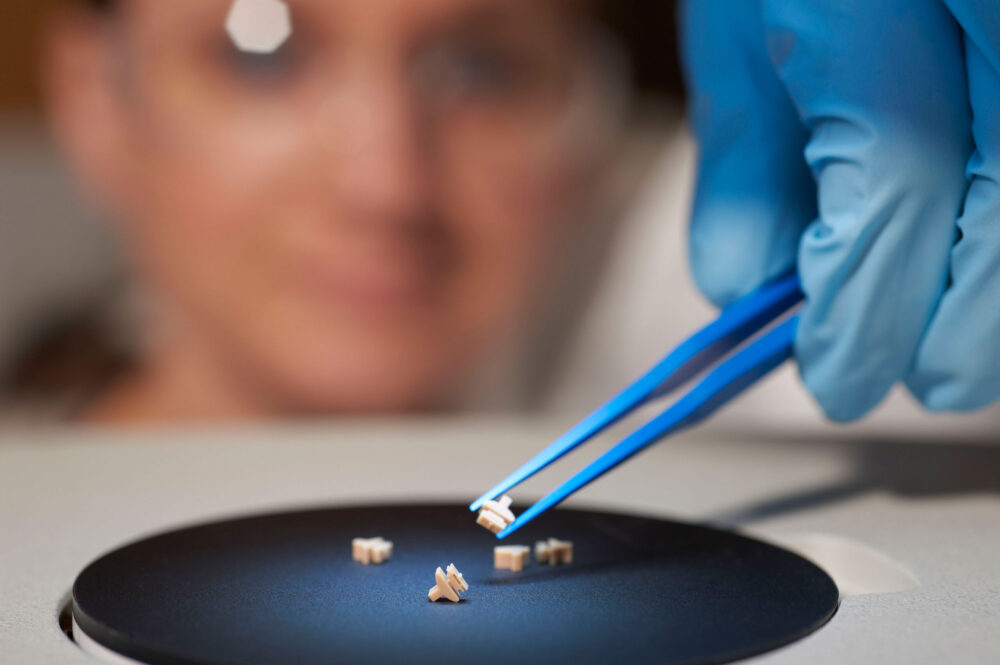

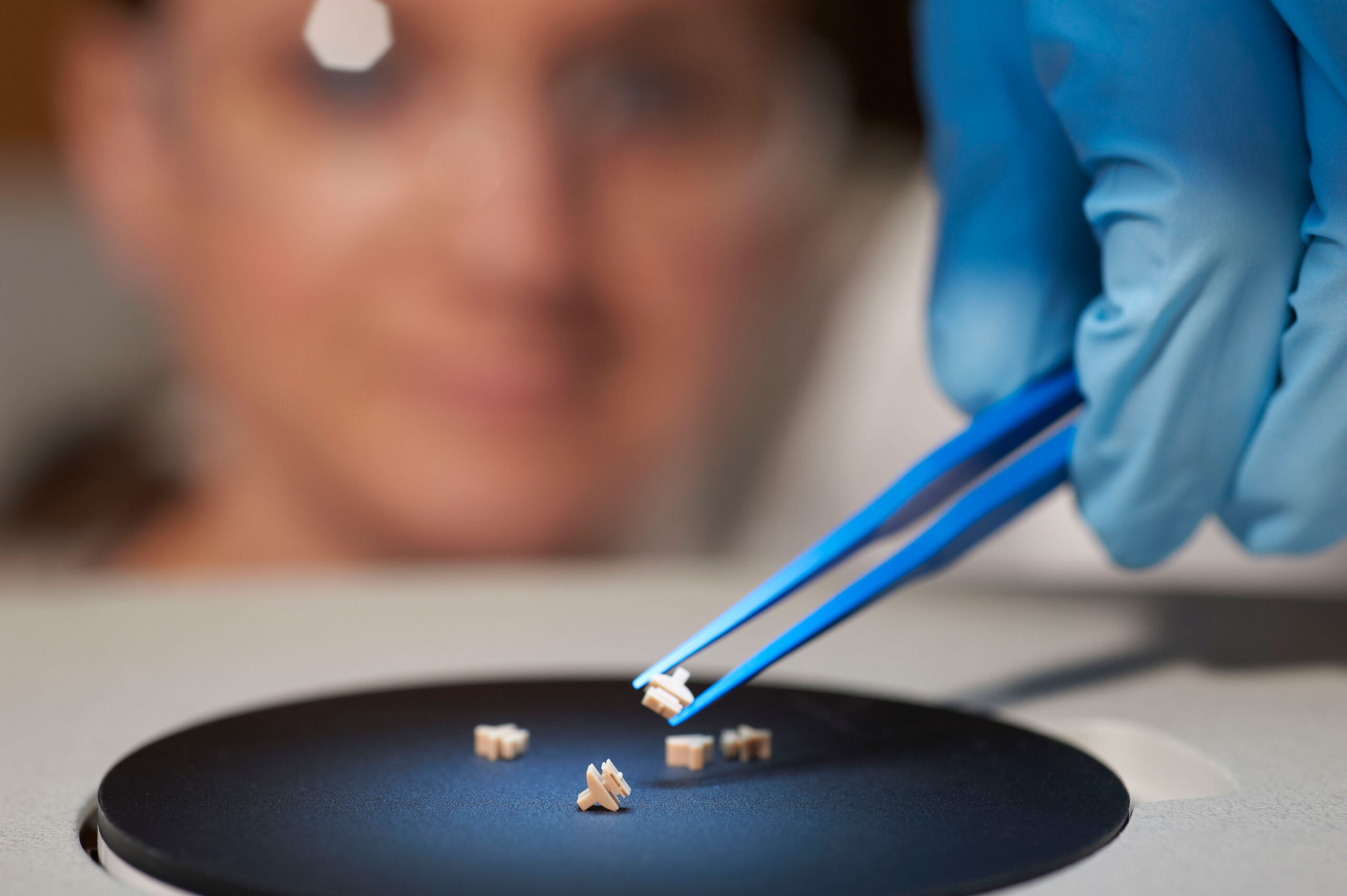

The medical device sector consistently demands ever smaller components and products that require increasingly stringent precision, often down to micron-level tolerances. To meet these requirements, manufacturers need processes that deliver flawless repeatability and zero failure rates — critical for products intended for safety-sensitive applications.

Companies operating at the forefront of design and manufacturing innovation, such as Accumold, are essential partners in this effort. Accumold has been a leading innovator in micro molding since 1985, earning global recognition for its ability to manufacture highly intricate plastic parts with extreme precision, often measured in microns.

One of Accumold’s unique strengths lies in its vertical integration, enabling the company to serve as a comprehensive partner in the design and manufacturing of medical devices. Offering a full suite of services under one roof, the company supports customers with everything from material and design guidance to micro tool fabrication, proprietary molding processes, and advanced metrology. Additionally, it provides automated assembly and other services that streamline product development for optimal efficiency, cost-effectiveness, and speed.

According to Petra Badrah, Accumold’s Business Development Manager for Europe, “Our collaboration with leading medical device manufacturers worldwide is something we take great pride in. We are involved in every stage of the process, ensuring that our customers’ product development efforts are efficient and cost-effective. Our 40+ years of experience give us an edge as not only the largest but also the most experienced micro molder globally. This means our clients benefit from the certainty of working with a stable, reliable partner capable of producing cost-effective solutions and scaling up to full mass production when needed.”

Accumold’s reputation for delivering consistent, high-quality, and repeatable production is backed by its ISO 13485 certification — an internationally recognized standard for quality management in medical devices. The company’s scale allows it to produce quantities ranging from prototypes to millions of parts. This capability makes it an indispensable ally in the medical device industry, helping product designers turn their innovative concepts into reality.

Petra Badrah adds, “At Accumold, we focus on delivering timely, cost-effective, and innovative solutions through close collaboration with our customers. We maintain transparency at every stage of the product development journey. By combining our deep expertise with a solution-driven mindset, we are often able to create medical devices and components that others consider impossible to manufacture. We invite all Compamed attendees to visit our stand and explore the remarkable parts we’ve produced. We’re excited to discuss how Accumold can help bring your medical product ideas to life.”