As the automotive industry faces unprecedented technological advancements, the need for precision, reliability, and safety in components is more critical than ever. With electric vehicles gaining traction, and autonomous driving on the horizon, the quality of each part that goes into a vehicle can mean the difference between smooth performance and critical failure. At the forefront of meeting this challenge is micrometal Group, a leader in photo-chemical etching (PCE) technology. The company’s finely engineered components, from filters to interior grilles, are playing an essential role in pushing the boundaries of automotive safety and performance.

Jochen Kern, Head of Sales and Marketing at micrometal Group, sheds light on the growing demands of the industry, “As vehicles become more sophisticated, the parts within them need to be even more precise, reliable, and long-lasting. Our PCE processes, whether sheet or reel-to-reel allows us to create components that meet the incredibly high standards of today’s automotive manufacturers, ensuring better safety, efficiency, and overall vehicle performance.”

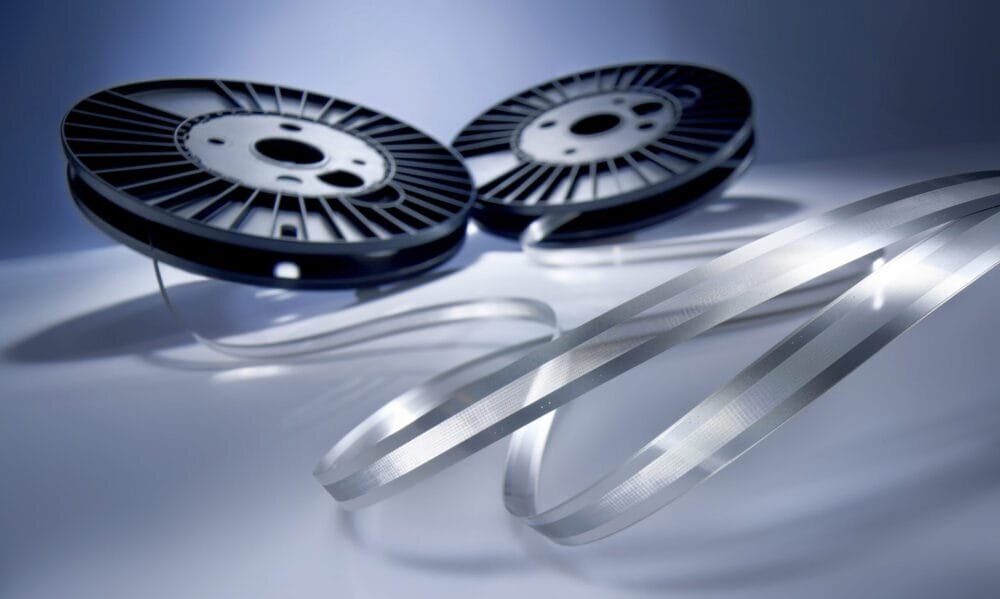

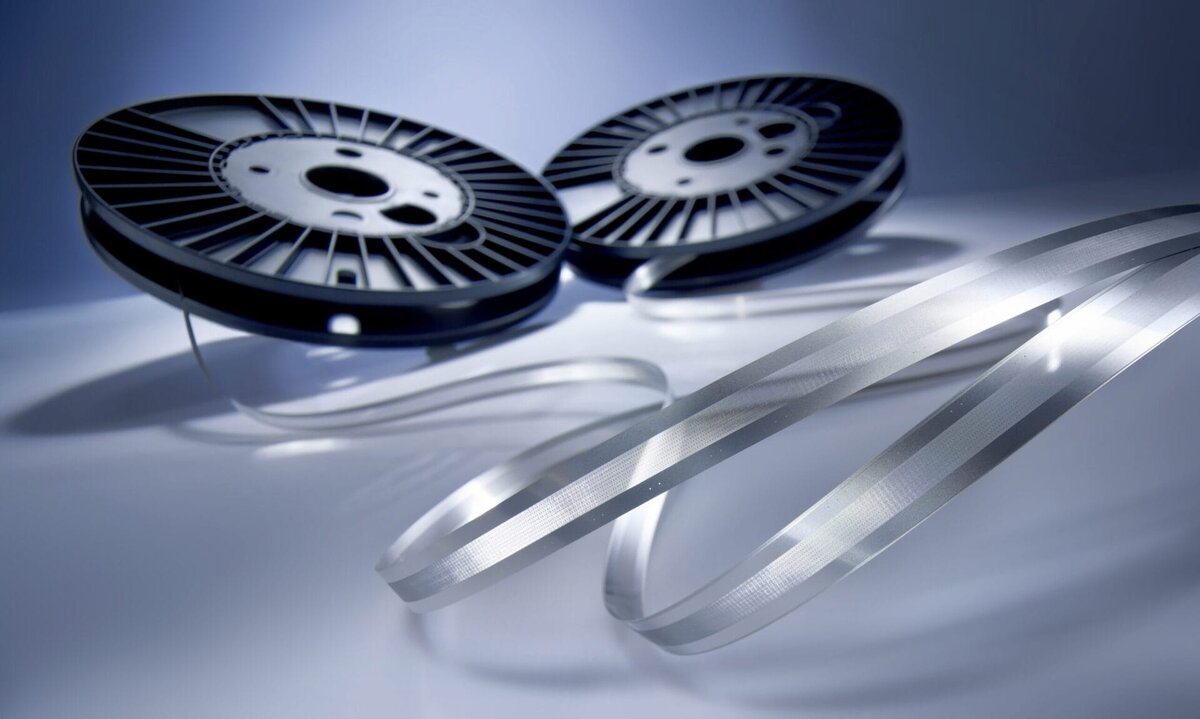

One of the key advantages of PCE for automotive applications is its unparalleled precision. Automotive components such as micro-filters and sieves need to operate flawlessly under extreme conditions, from intense heat to vibration, without losing integrity. micrometal Group’s etched filters are essential for keeping fuel and air systems clean, which is crucial to maintaining optimal engine performance. Even the smallest imperfection can lead to contamination, reducing efficiency and ultimately increasing wear and tear on the engine.

“Our precision-etched filters are designed to last,” explains Kern. “They are engineered to exacting tolerances, ensuring that no harmful particles get through while maintaining the flow needed for peak engine performance. The reliability of these components directly translates into enhanced safety and a longer lifespan for the vehicle.”

Another area where micrometal Group’s precision components excel is in automotive interior grilles. These are not just decorative elements but play a vital functional role in airflow management within the vehicle. From ensuring proper ventilation for electronic systems to improving cabin comfort, the role of these grilles is multi-faceted. With PCE, micrometal Group can produce complex, intricate designs that would be difficult or impossible to achieve with traditional methods such as stamping or laser cutting.

Kern emphasises the advantages of using PCE, “The freedom of design that photo-chemical etching allows is a game-changer for our automotive customers. We can create highly detailed, burr-free components that perfectly balance form and function. This means better performance for critical systems and an improved driving experience for the end customer.”

Beyond the immediate benefits of precision and performance, micrometal Group also excels in delivering scalability and cost-effectiveness — two crucial factors for automotive manufacturers. The flexibility of the PCE process allows for rapid prototyping and seamless transitions to high-volume production without the need for costly retooling. This makes it easier for automotive manufacturers to innovate and adapt quickly to market demands, while still maintaining the high quality and consistency required for safety-critical components.

“Automotive manufacturers are under constant pressure to innovate,” says Kern. “By partnering with micrometal Group, they gain access to a manufacturing process that not only meets today’s needs but is future-proofed for tomorrow’s challenges. We enable them to scale their operations efficiently while maintaining the strict quality control necessary for ensuring vehicle safety.”

micrometal Group’s commitment to quality is underscored by its certifications, which include ISO 9001 and IATF 16949, specifically focused on automotive industry standards. This adherence to rigorous quality control processes ensures that each part the company produces meets the highest levels of precision and reliability, contributing to the safety and performance of vehicles on the road today.

“At micrometal Group, we believe that innovation and quality go hand in hand,” Kern concludes. “Our mission is to continuously push the boundaries of what’s possible with PCE, ensuring that our components not only meet but exceed the demands of the automotive industry. We take pride in knowing that our work contributes directly to the safety and performance of vehicles, making the roads safer for everyone.”

With PCE at the core of its production process, micrometal Group is not only meeting the challenges of today’s automotive market but driving the innovations that will shape the vehicles of tomorrow.