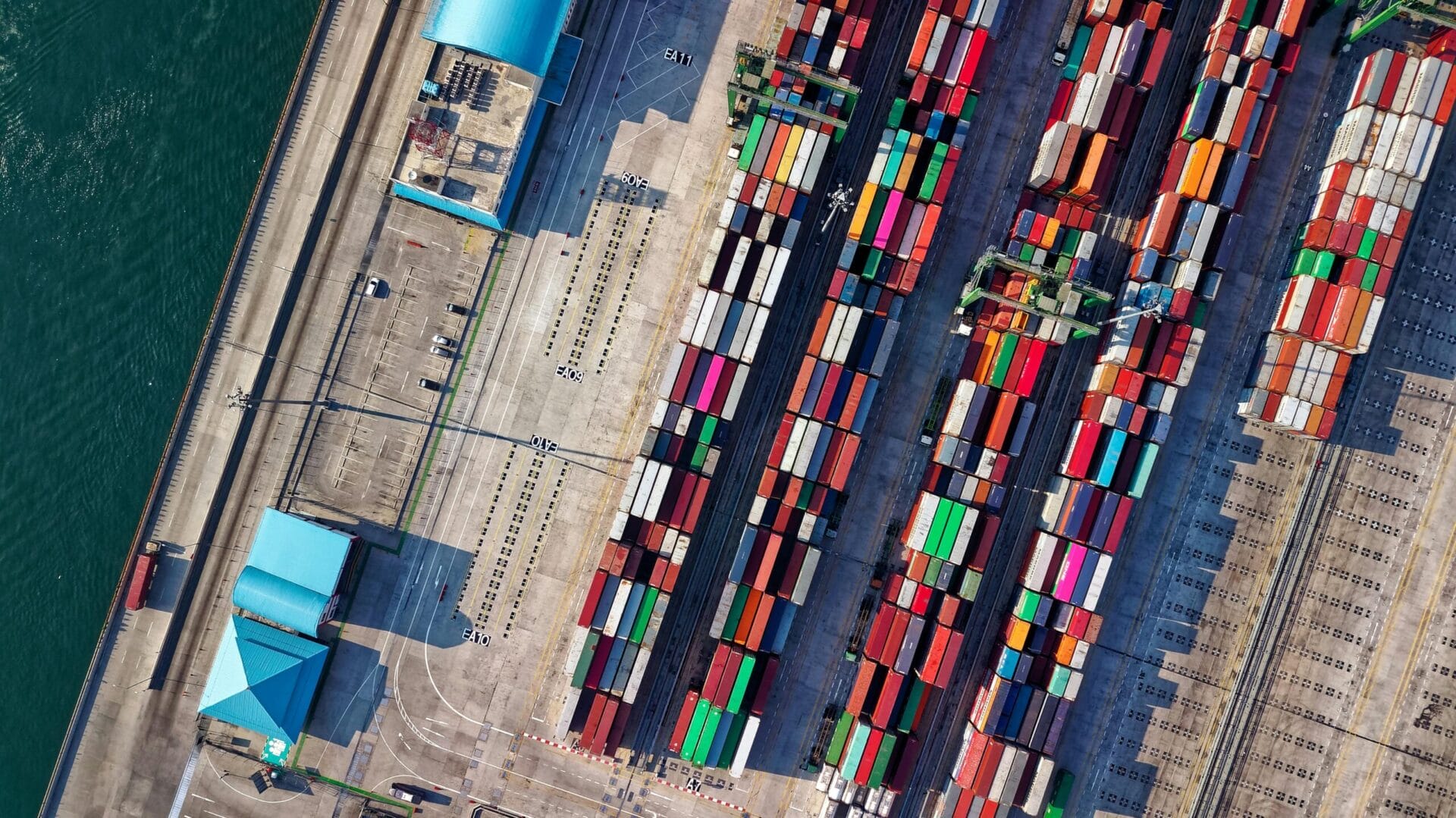

From global shortages of materials to transport delays and lack of personnel, supply chains in the UK have experienced several issues in recent years, with at least 20% of businesses experiencing some sort of disruption.

93% of companies expect the pressure on supply chains in our country to persist throughout 2024, meaning their operations might suffer as a result. But the good news is that, even if most organisations have made necessary adaptions to limit problems with their supply chain, further steps can be taken to enhance and refine the process.

Cleveland Containers, a leading supplier of 40 ft shipping containers in the UK, offers expert insight on the best ways to optimise your supply chain, from investing in the right technology to fostering collaboration.

Plan carefully

First things first, planning ahead and carefully is arguably one of the most critical segments to ensure a smooth supply chain process.

Hayley Hedley, Head of Commercial at Cleveland Containers, said: “Planning in a timely fashion is crucial, especially when it comes to order fulfilment.

“This is because it will allow you to prevent potential issues with your logistics chain and avoid delays that could leave you without the raw materials and products you need to seamlessly carry out your operations. What’s more, if you fail to plan your orders early, you may end up in a situation where you’ll have to ask for urgent deliveries – and added costs can rack up pretty quickly.

“Planning carefully includes looking at any potential process change, evaluating how it might impact the flow of your supply chain and whether it might affect your bottom-line gains.

“This gives you the opportunity to prepare and account for worst-case contingencies. Hopefully, they will never happen – but if they do, you will have a plan of action to tackle them effectively and with confidence.”

Promote communication and collaboration

Communication and collaboration are the lifeblood of any organisation, as they create an environment where expectations are clear and everyone rows in the same direction.

In addition to fostering cooperation among various departments within your business, it is important to extend a culture of open communication with your suppliers and logistics providers. In fact, this can promote a stronger sense of trust, improve responsiveness to changes, eliminate confusion, and lead to a more fruitful relationship overall.

If you are using more than one supplier, communication and collaboration become even more essential. By staying in constant touch with all your suppliers, you can keep everything ticking as it should without the risk of delays or misunderstandings.

Take advantage of analytics tools

Harnessing the power of data analytics is another great way to optimise your supply chain and give your business a competitive edge.

For example, analytical tools allow you to evaluate your sales figures, understand customer preferences, and predict future demands.

Based on the data, you can then make more conscious and confident business decisions, such as forecasting demand and recalculating inventory levels to suit both your business and customers’ needs.

In short, analytics tools allow you to monitor customer behaviour, keep your stock at appropriate levels, and contact your supplier with more accurate orders and requests.

Embrace technology

Technology can act as a much-loved friend in terms of streamlining processes and optimising supply chains.

Interestingly, almost half of UK businesses (46%) are not yet relying on modern tech, such as AI, robotics, machine learning, and augmented reality, in their day-to-day activities.

However, embracing innovations can have a wide range of benefits when it comes to improving speed and accuracy. For example, blockchain technology can automate repetitive and physically draining processes, increase visibility, and enhance decision-making within the supply chain.

What’s more, implementing specific software can aid inventory management, allowing to track locations in real-time and facilitate operations within the warehouse.

From planning in advance to promoting collaboration, there are many steps you can take to optimise your supply chain and ensure your business is operating constantly at its best.

So, despite the challenges of recent times, having a few handy tips can make the all-important difference between struggling with disruptions and maintaining efficiency at prime levels.