Automation software supplier COPA-DATA has recently released the latest version of its industrial software platform, zenon 15. Designed to bridge the gap between operational technology (OT) and information technology (IT), the new version marks a significant step toward centralized, secure and future-ready industrial systems. zenon 15 introduces more than 230 new features and enhancements, delivering intuitive engineering, advanced data usage and seamless cross-platform operation — from the machine to the cloud.

“Our development philosophy for zenon remains centered on people: reducing complexity, simplifying processes and making automation accessible to teams of all sizes and backgrounds,” says Lukas Punzenberger, Director Product Management at COPA-DATA. With the release, the family company again emphasizes its core competences — usability and interoperability.

Web-first, cross-platform, cloud-ready

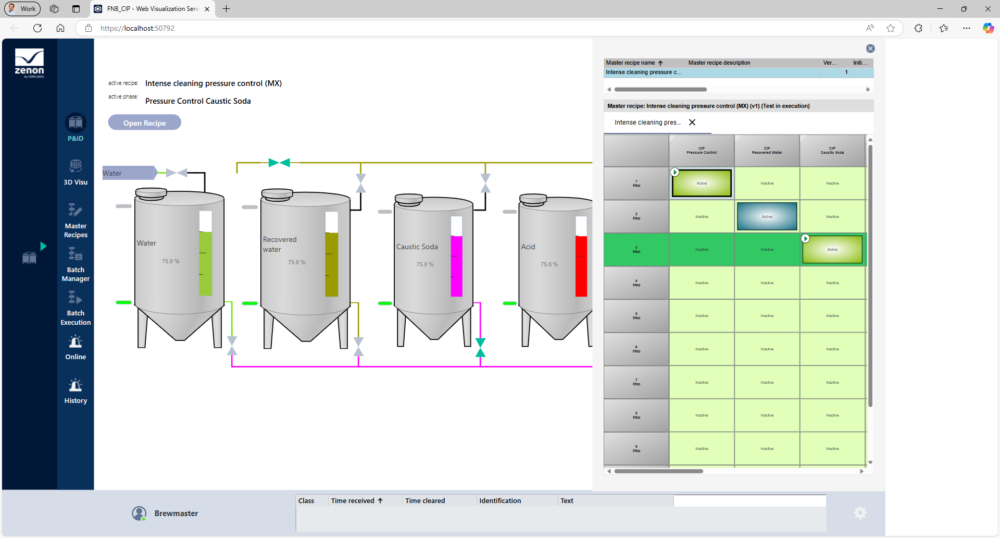

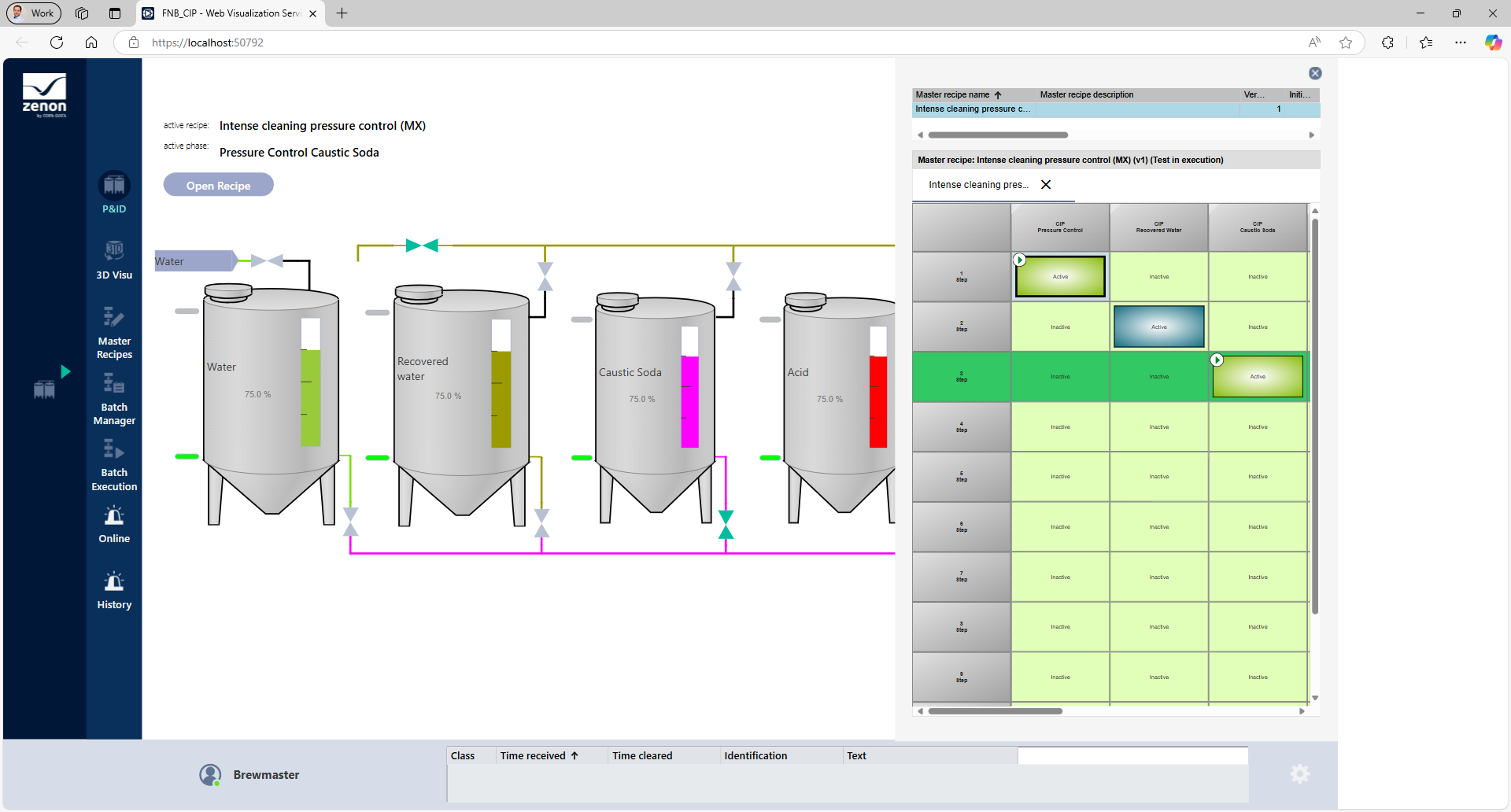

With zenon 15, COPA-DATA expands its support for HTML5-based web visualization, enabling fast and intuitive screens that work seamlessly across browsers. New features like enhanced dashboards, web-based matrix recipe visualization in batch production and Automatic Line Coloring (ALC) give distributed teams greater transparency and real-time control.

“The extended Industrial Internet of Things (IIoT) Services of zenon 15 bring even more intuitive centralized management to the shop floor. We’ve streamlined workflows and made complex systems easier to configure, monitor and scale. zenon 15 is all about bridging the worlds of IT and OT,” emphasizes Punzenberger. “We’ve closed many of the long-standing gaps between them. From data collection to visualization in advanced web applications — everything happens in one secure, unified environment.”

Containerized support for Linux also continues to advance. The zenon Service Engine — the core runtime software that executes control logic, processes data and manages system communication — can now be deployed as a process server in mixed operating system (OS) environments.

Importantly, regardless of whether the final project needs to run on Windows or Linux, there is only one engineering environment needed — a major step forward not only in terms of interoperability but also in software-defined automation and virtualization. This gives engineering teams greater flexibility to develop, scale and manage automation projects securely and efficiently.

Bridging OT and IT

The zenon Logic built-in programming environment also now supports Python, the widely used and easy-to-read programming language, alongside IEC (International Electrotechnical Commission) 61131-3 specified ones, combining the strengths of IT and OT. This allows engineers to use an additional programming language in order to automate processes, analyze data and even integrate artificial intelligence (AI) functions directly in the control layer. zenon Logic now supports the Extensible Markup Language (XML)-based exchange format in accordance with IEC 61131-10 to enable the platform-independent exchange of data.

COPA-DATA / Michael Schartner

Lukas Punzenberger, Director Product Management at COPA-DATA, says that COPA-DATA’s development philosophy for zenon remains centered on people.

Smarter security and user management

Cybersecurity is a central concern across all industries. With zenon 15, COPA-DATA responds to both technical and regulatory demands for example by expanding its user management system to support over 65,000 permission roles. Projects can now be mapped to equipment-specific roles, and the documentation lists a mapping table to IEC 62443-4-2. The standard is a recognized cybersecurity framework for industrial automation and control systems. This means that certifying the customer’s zenon application according to this important security standard is simplified.

COPA-DATA

zenon 15 offers enhancements within the Web Visualization Service like the Automatic Line Coloring (ALC) and matrix recipe visualization.

Industrial intelligence for every sector

zenon 15 also delivers industry-specific enhancements tailored to energy, food and beverage, pharmaceutical and infrastructure applications. New drivers and extended protocol support — including building automation applications and Open Platform Communications Unified Architecture (OPC UA) historical data access — enhance connectivity and data integration. Improved Batch Control and IIoT dashboard widgets further highlight the platform’s evolution into a central hub for modern industrial control systems.

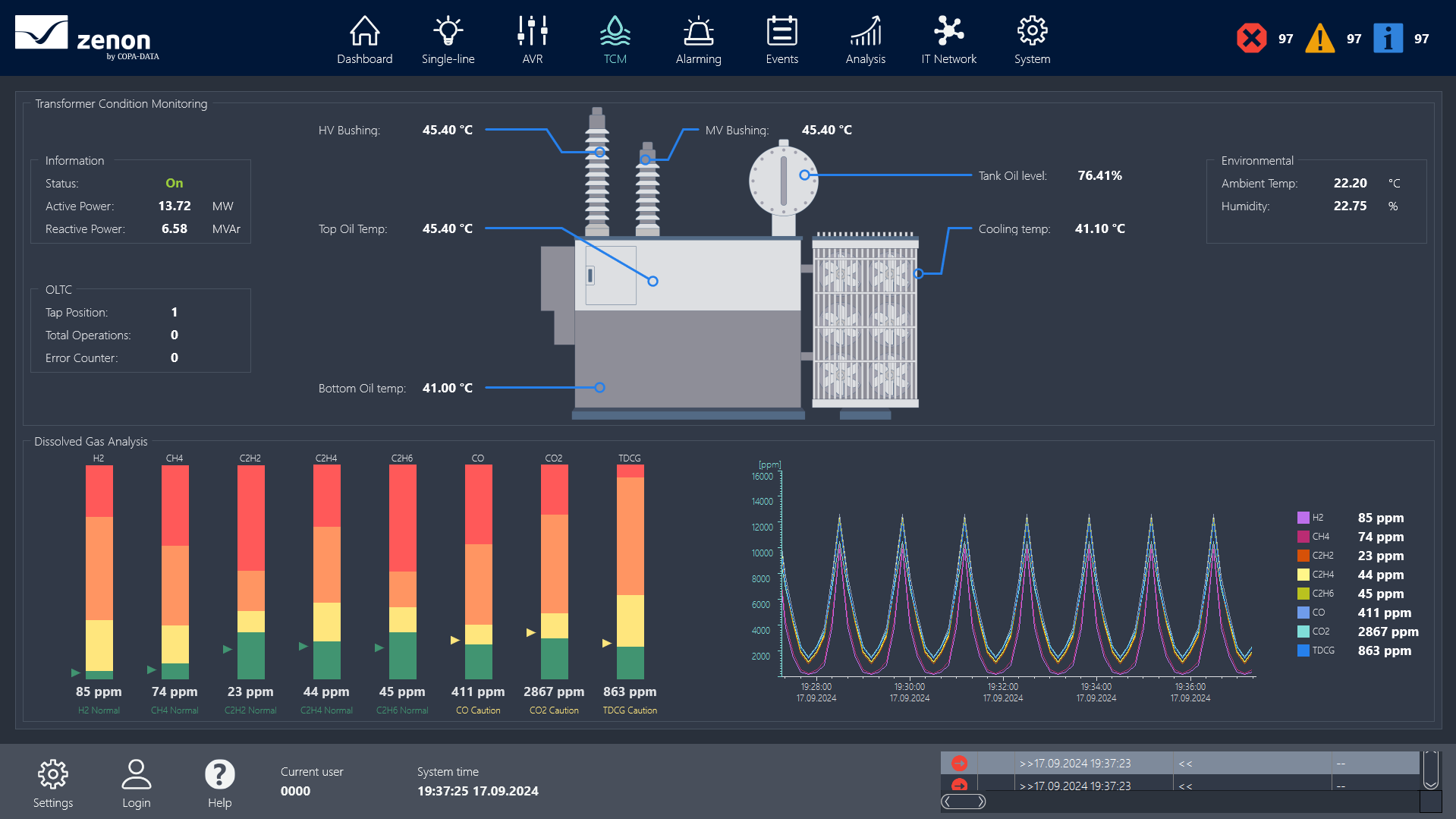

In the energy sector, for example, zenon 15 supports enhanced HTML 5 visualization and command processing for substations, including ALC and secure multi-client authorization. In pharmaceutical and life sciences environments, it supports PAS-X Message-Based System Integration (MSI) Plug & Produce certification, which enables rapid, standardized equipment integration. zenon 15 will meet full Module Type Package (MTP) 2.0 compliance requirements to enable modular, regulation-compliant production automation as soon as the updated standard is released.

COPA-DATA

The screen shows the HTML 5 web visualization of a substation.

More clarity, control and collaboration

The development of zenon 15 involved over 1,100 user stories which led to 7,000 Git commits — the version control system developers use to track changes in code —, which demonstrates COPA-DATA’s strong focus on collaboration and continuous improvement. “Whether you’re modernizing legacy infrastructure or launching a new greenfield project, zenon 15 gives engineers, operators and decision-makers the tools they need to work smarter — with greater clarity, control and collaboration across systems, sites and disciplines,” says Punzenberger.

To learn more about zenon 15, visit www.copadata.com/current-version