~ How to strike a balance between cable performance and resilience ~

In aerospace and military defences, cables hold vast mechanical responsibility. Quietly operating in the background, they are expected to successfully transmit signals and data in some of Earth’s harshest conditions, needing to withstand extreme winds, temperatures and vibrations. The main challenge lies in achieving the optimal balance between cable performance and rugged resilience. Here, Jeff Wood, sales director at mil-spec cable specialist WireMasters, explains the importance of both performance and resilience in wiring solutions for aviation and military, and how to find a middle ground that best fits the application.

Often, a successful cable design is associated with its speed or bandwidth. While both qualities contribute towards high cable performance, durability can consequently be overlooked. However, a resilient cable provides longevity, ruggedness and reliability, which are crucial to aerospace and military applications in demanding environments. Instead of maximising one or the other, good cable solutions intelligently integrate both performance and durability into their designs.

Performance vs resilience

Performance is more than just speed. A cable’s performance refers to its ability to deliver consistent, reliable data power or signal transmission. High performance cables, like ethernet cable CAT8, are suitable for data centre applications like switch-to-switch communications, due to braided copper shielding that minimises electromagnetic interference (EMI). This level of EMI resistance from shielding maintains signal integrity which is responsible for delivering consistent transmission.

Resilience is more about whether the cable keeps functioning, especially when deployed to hostile environments. When designing a rugged cable, there is more focus on materials. Polyurethane (PUR) in jacketing for example, provides resistance to abrasion, fluid exposure and chemical wear, with PUR-jacketed cables commonly achieving an Ingress Protection (IP) rating of IP65 to IP69<.

In some applications across aerospace and military, high performance isn’t enough. A lightweight Ethernet cable for instance seems like a suitable solution for military mobile radar trackers. With bandwidth ranging from 250 megahertz (MHz) to 1000 MHz and minimal signal loss, it’s clear why. However, in the field, these cables have failed within weeks of deployment, being unable to withstand hydraulic fluid exposure, a constant presence in radar trackers. Despite the high performance, the cables failed due to physical wear.

The engineering trade-offs

Designing a cable that intertwines both performance and resilience takes calculated compromise. To strike this balance, everything from material selection to technical specifications must be considered to establish competing priorities.

High-bandwidth cables are constructed with precision. Low loss dielectrics, tightly wound foil shielding and copper alloy conductive cores amount to high performing flexible cables, but limitations arise from their lightweight nature making them less rugged. Foil shielding for example, while it serves as an efficient mitigation method for EMI suppression, it can crinkle or even tear under vibration. In an aircraft, vibration is a frequent occurrence meaning that such cable systems need to be able to withstand the shock otherwise they fail.

On the other hand, resilient cables encounter trade-offs with mechanical flexibility. Thicker jacketing and heavy insulators make them heavier, less space efficient and harder to route. In an aircraft, flexibility is essential for routing through tight bends and spaces, so while these ruggedised cables withstand the constant vibrations, they’re insufficient for some aircraft applications like avionics bays and line-replaceable units (LRUs) which are confined and require cables to bend sharply without causing signal loss.

When it comes to both performance and resilience individually, a cable can meet all of its specifications on paper yet still fail in the field. Combatting this requires engineers to consider application context; understanding where the cable will be used, external factors, is it for a temporary mission or expected to last for 30 years, and what happens if it fails?

By understanding the operational context as well as tech-specs, engineers can make smarter decisions about design, materials, shielding and routing to ensure suitable levels of both durability and performance.

Delivering application-specific connections

When designing cables beyond performance specs, engineers must pay attention to materials that withstand the real-world conditions of the application with shielding, and jacketing falling into key consideration areas.

In shielding, materials often facilitate reduced EMI and radio-frequency interference (RFI). Although it also plays a role in a cable’s mechanical structure and physical resilience. For example, foil shielding comprised of aluminium-polyester tape combined with braided shields uses the properties of both features to optimise performance and durability. Braiding acts as an additional layer which protects the thin foil from vibration damage, ensuring high-frequency EMI protection and physical resilience.

Extra levels of armour come from jacketing, both PUR and Perfluoroalkoxy (PFA). Suitable for dynamic defence applications like naval vessel galleries, PUR and PFA offer a low smoke alternative to polyvinyl chloride (PVC). While both have similar properties, providing exceptional fluid resistance and chemical inertness, PFA is superior from a temperature perspective operating in up to 260°C and PUR offers greater abrasion resistance with many PUR-jacketed cables meeting IP67–IP69K ratings.

Each resilient feature can be moulded to fit the context of an application. When configuring aerospace and defence cable solutions, WireMasters collaborate closely with engineers who require both performance and reliability. By understanding the real-world case, whether it’s mission critical application or a static control interface, a realistic balance is achieved. As a Mil-Spec cable specialist, WireMasters expand on knowledge and experience working in the defence sector to build on solving these complex trade-offs intelligently and reliably.

The future could see further developments in current innovations across the market. Both miniaturisation and hybrid cable configurations, hold promise in enabling lightweight components that are both powerful and resilient enough to handle critical aerospace and military systems even in the world’s most ruthless environments. But right now, whether it’s for a next-gen satellite or military ground communication system, engineers must adopt an application devoted approach in building smarter, long lasting cable systems for these industries.

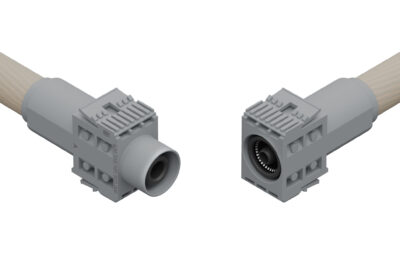

For more information on Mil-Spec connectors and to explore available options, contact WireMasters at www.wiremasters.com.