Jochen Kern, Head of Sales & Marketing, Micro Component Group.

In high-tech manufacturing, progress isn’t measured in giant leaps. But it is often measured in microns. As industries such as aerospace, automotive, and medical devices push the limits of design, performance, and miniaturisation, manufacturers are being asked to deliver more functionality in less space, with tighter tolerances and uncompromising reliability. This is the environment in which photo-chemical etching (PCE) is proving itself not only as a capable process but as an essential enabler of next-generation engineering.

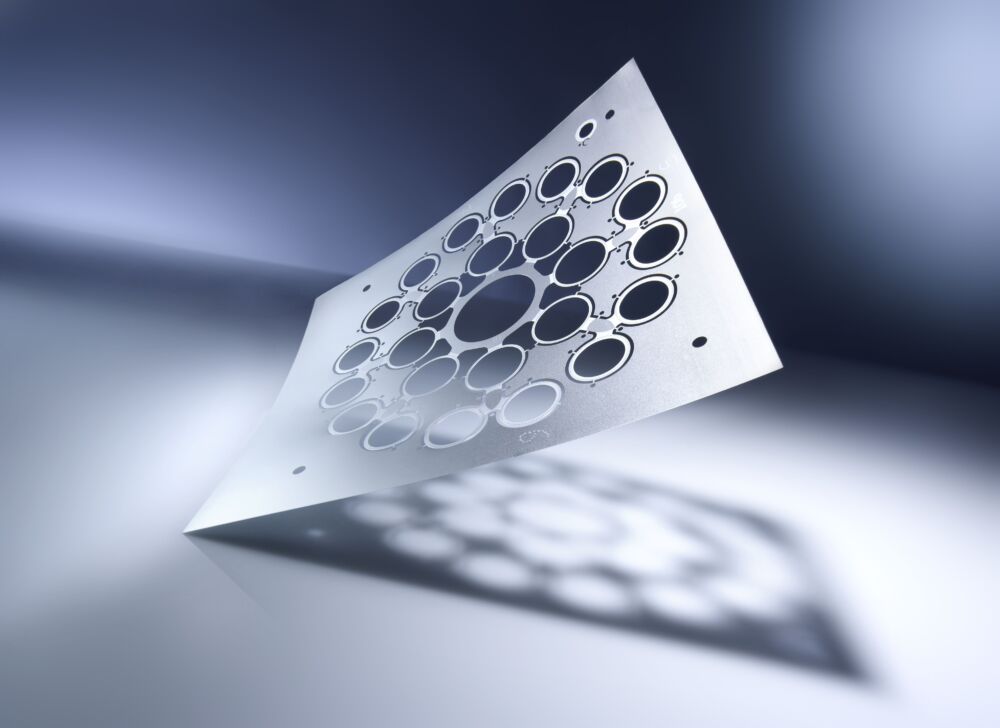

PCE is a subtractive manufacturing technique that uses light-sensitive photoresists and controlled chemical etchants to produce extremely precise metal components. Unlike mechanical methods such as stamping or CNC machining, PCE introduces no mechanical or thermal stress, making it ideally suited to thin, complex, and fragile structures. The advantages go beyond geometry. PCE is digital-tooling-based, which allows for faster design iteration, lower setup costs, and no deformation or burrs, regardless of the complexity of the part. This makes it ideal not just for precision, but for innovation across multiple industries.

AEROSPACE

For the aerospace industry, where weight, reliability, and performance must be balanced with rigorous safety requirements, PCE supports innovation at both the component and system level. Complex geometries, ultra-fine filters, fluidic channeling, and lightweight structural elements can be fabricated in ways previously unachievable. When used to manufacture EMI/RFI shielding, thermal spreaders, or jet engine instrumentation elements, PCE offers the repeatability and precision necessary to perform under extreme conditions. Components etched with PCE often weigh less, fit more tightly into compact systems, and require minimal post-processing. In an industry where even fractional reductions in weight can lead to significant gains in fuel efficiency and payload capacity, the value of lightweight, high-precision parts cannot be overstated.

AUTOMOTIVE

In the automotive sector, PCE is proving critical to both electrification and autonomous technologies. The rapid expansion of EVs and driver-assistance systems demands precision metal parts for battery systems, sensor housings, and control modules. As vehicle electronics grow more sophisticated, the need for thermal control, signal shielding, and miniature electronic interfaces becomes ever more pronounced. PCE enables the production of heat shields, micro-mesh filters, and lead frames that are lighter, more compact, and more reliable than those made by traditional means. The non-contact nature of PCE ensures that even the most delicate structures maintain their integrity, a crucial requirement in high-vibration environments like automotive applications.

Beyond component size and weight, automotive engineers increasingly value the design flexibility that PCE enables. Design modifications can be made quickly and affordably without altering hard tooling. This becomes a strategic advantage in an industry racing toward shorter development cycles and increasing product customisation. As software-defined vehicles grow in popularity, the need to accommodate ever-changing hardware specifications with adaptable manufacturing solutions becomes a critical differentiator. PCE’s ability to deliver this flexibility is a significant asset.

MEDICAL DEVICES

When it comes to medical devices, PCE enters an entirely different class of critical application. Devices used in diagnostics, drug delivery, and surgical procedures require not only exceptional precision but also biocompatibility, surface cleanliness, and batch repeatability. The demand for burr-free, stress-free components with ultra-sharp edges and intricate geometries is high, and PCE delivers. From fine mesh implants to microfluidic plates, surgical blades to biosensor components, PCE ensures exacting performance while preserving material integrity. With no heat-affected zones, PCE maintains the metallurgical properties of the base material, which is crucial in medical contexts.

Furthermore, the rapid iteration capability of PCE is invaluable during device development and prototyping phases. Without the delays and costs associated with hard tooling, medical OEMs can accelerate validation cycles and respond quickly to clinical feedback, all while maintaining strict dimensional and quality standards. This responsiveness can shorten time-to-market, enabling medical innovations to reach patients faster, a vital advantage in the fast-paced world of medtech.

SHIFTING THE MANUFACTURING PARADIGM

Beyond its technical benefits, the adoption of PCE across high-tech industries reflects a broader shift in manufacturing strategy. Flexibility, scalability, and speed-to-market have become as important as part quality. As digital transformation accelerates, manufacturers are embracing technologies that allow them to adapt quickly to evolving specifications, supply chain variables, and market demands. The ability to remain agile in response to shifting conditions is no longer a bonus, it is a baseline requirement for remaining competitive.

PCE is uniquely suited to this environment. Because the process relies on photomasks rather than mechanical tooling, manufacturers can adjust part designs on the fly without incurring additional tooling costs. This empowers engineers and product developers to experiment, iterate, and refine with minimal friction. In high-tech industries, where even small changes can yield major performance or cost improvements, this agility is invaluable. Whether adjusting for a last-minute spec change or pivoting to meet regulatory requirements, PCE offers the responsiveness needed to make it happen.

SUSTAINABILITY

The sustainability aspect of PCE should also not be overlooked. Traditional subtractive manufacturing methods often result in high material waste, energy consumption, and extensive secondary processing. PCE, by contrast, uses only the necessary amount of material, creates minimal scrap, and requires no energy-intensive post-processing. For industries striving to meet environmental goals or regulatory standards, this leaner approach to manufacturing presents a compelling advantage. With increasing focus on green design and lifecycle sustainability, the environmental footprint of the manufacturing process is becoming a key metric, and PCE performs strongly.

TCO

It is also important to consider the broader economic implications of PCE. In a high-cost competitive environment, the total cost of ownership (TCO) for a manufacturing process is a significant factor. Because PCE eliminates secondary processes like deburring and reduces the need for rework or quality control intervention, it delivers a highly cost-efficient model without compromising on capability. This makes it especially attractive in high-volume, high-precision industries where time and cost efficiencies must coexist with extreme quality demands.

SUMMARY

The future of high-tech manufacturing will be shaped not just by what we make, but by how we make it. In this context, photo-chemical etching is more than a process, it’s a platform for innovation. It removes historical constraints on complexity, enables smaller, lighter, and smarter designs, and supports the speed, precision, and reliability that industries now demand as standard.

At the Micro Component Group, we see PCE as a critical bridge between today’s challenges and tomorrow’s breakthroughs. As manufacturers across aerospace, automotive, and medical sectors explore new ways to design and deliver cutting-edge products, PCE offers a precise, scalable, and future-ready solution. Our commitment to advancing this technology stems from our belief that truly innovative manufacturing should never stand in the way of great ideas, it should make them real.

In an era defined by miniaturisation, performance, and rapid evolution, high-tech industries need partners who can keep pace. Photo-chemical etching is how we keep that promise, one micron at a time.