To mitigate spurious switching and improve lift uptime at a London apartment complex, power quality and lift expert CP Automation supplied and installed a series of SineTamer devices. Having established the lift system wasn’t at fault, CP Automation supplied the lift manufacturer Schneider Lift Controls with the devices, which almost immediately reduced voltage distortion and stopped the fire control input from randomly becoming active and halting the cab’s travel.

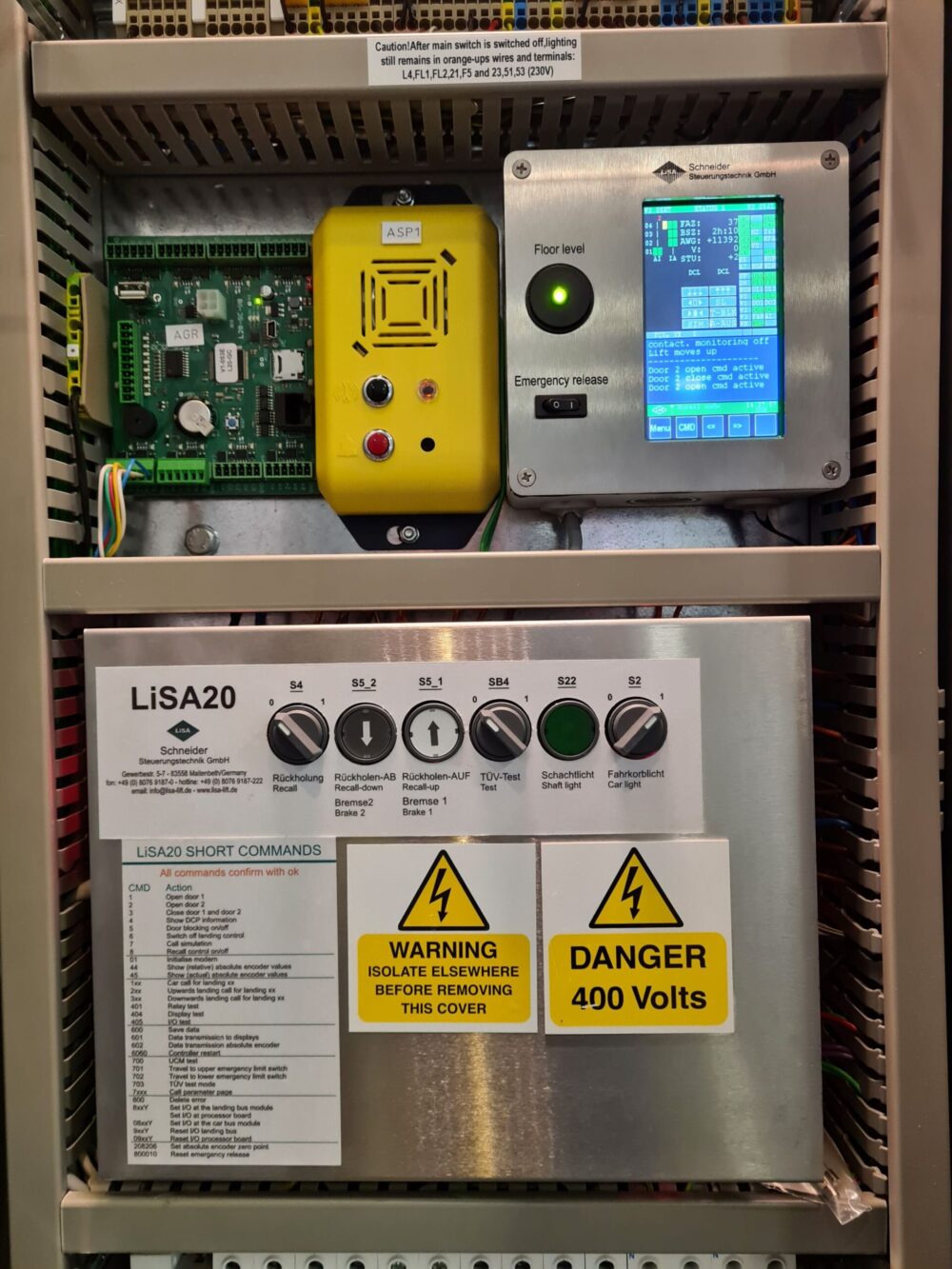

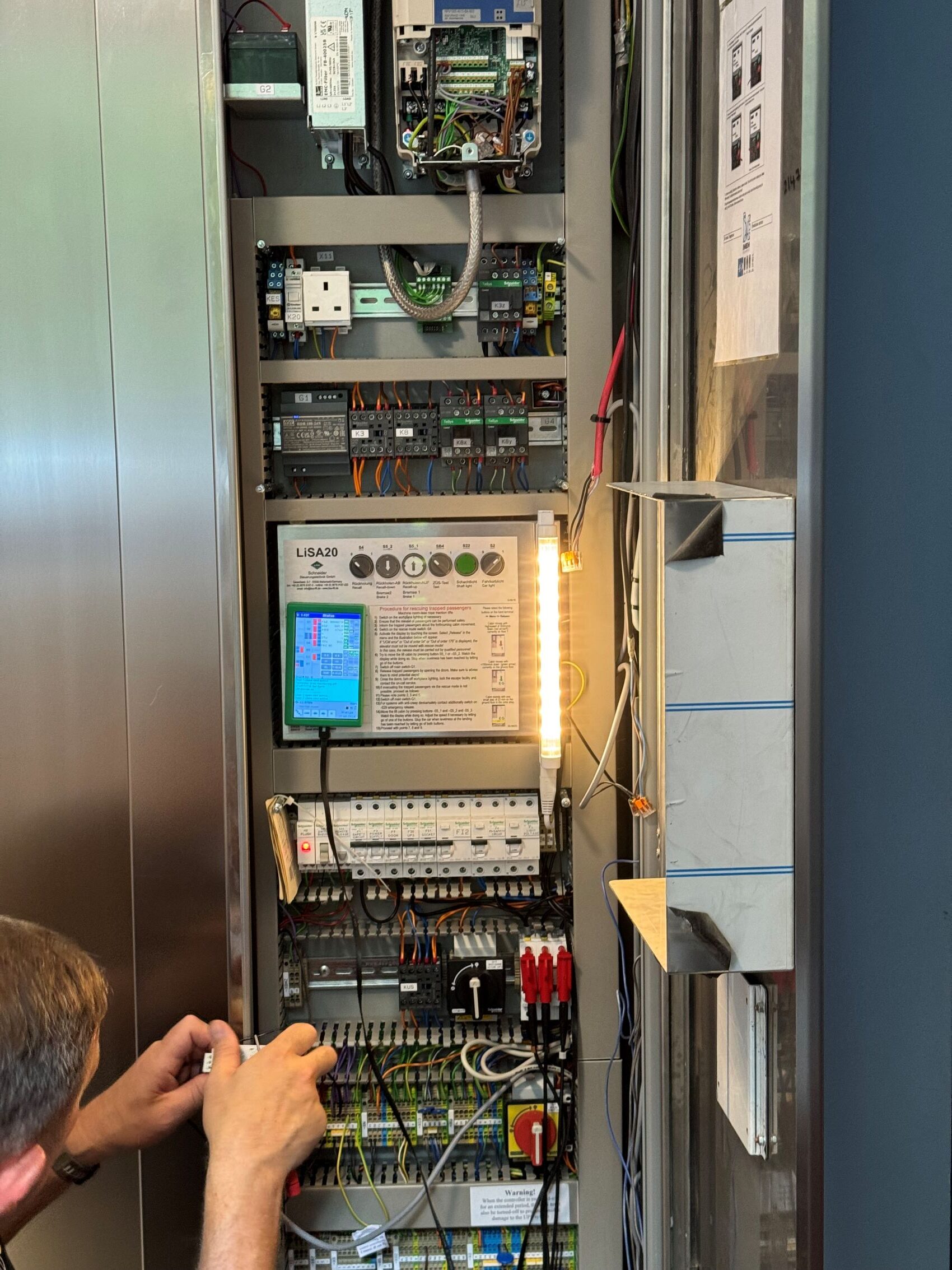

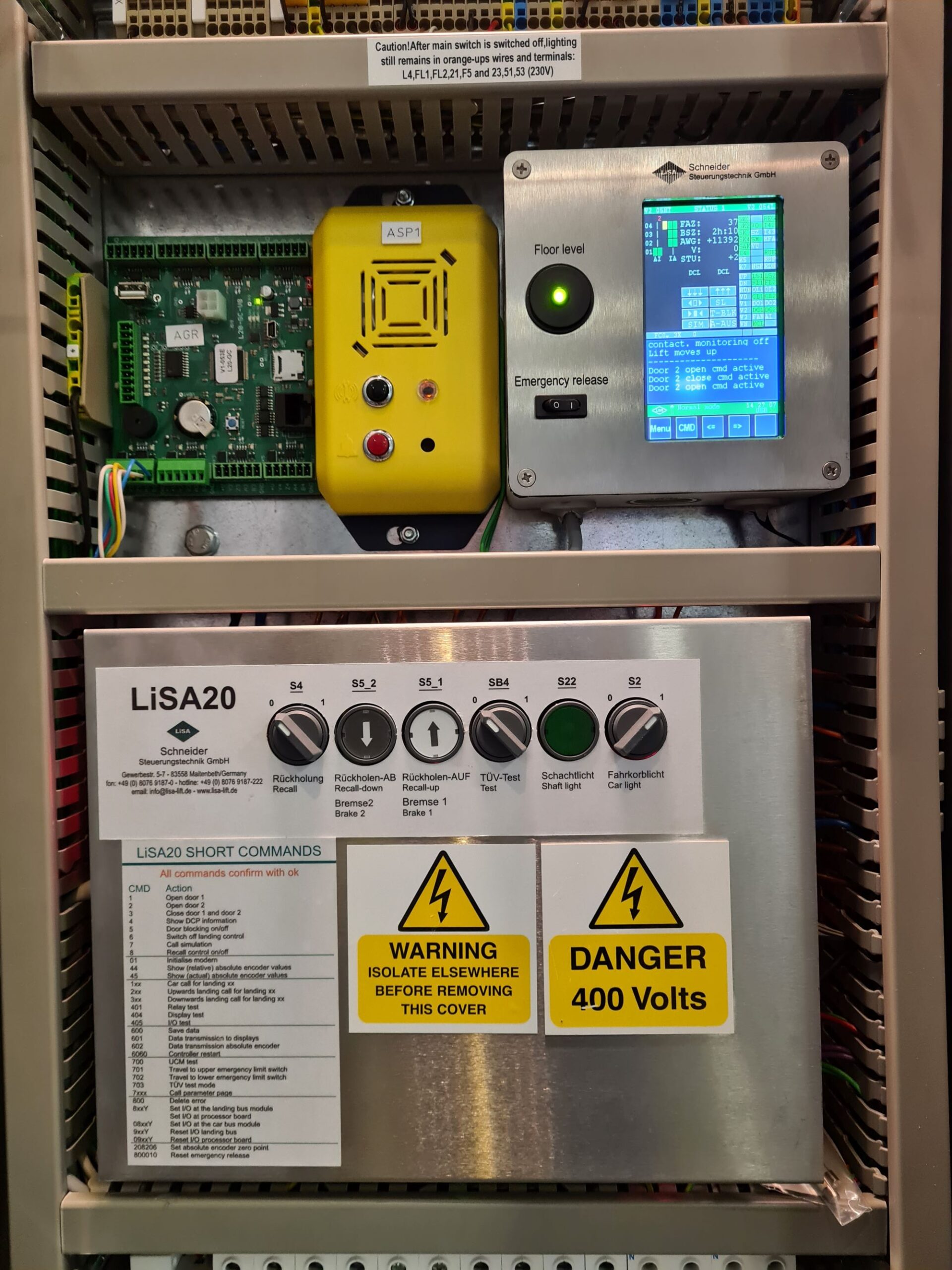

Like many residential buildings, the premium-serviced apartment complex uses lifts to transport residents and ensure accessibility, and the system had been installed by Schneider Lift Controls — an approved UK and Ireland supplier for the LiSA control system.

Following installation, the lifts began experiencing issues. The fire control input became active when the lift was in travel, despite the contact driving the input remaining open. The lift would randomly descend to the ground floor and be out of service, so passengers couldn’t call it from their floor.

“After extensive investigations, we established that the issue was external and unrelated to the control system,” explained John Merrill, managing director at Schneider Lift Controls. “As a temporary solution, we installed a galvanically-isolated contact that interfaced into the controller as a countermeasure to break the connection to the fire control input. While this was effective, we needed a more permanent solution. At this point, we brought in CP Automation.”

CP Automation conducted a power quality survey and initial frequency measurements revealed a cycle time of 125µs, matching the 8kHz carrier frequency of the variable speed drive (VSD).

Further analysis detected harmonic disturbances up to 104kHz, with poor-quality earthing emerging as an issue. Supraharmonic levels exceeded acceptable limits, and during our visit the site’s total harmonic distortion voltage (THDv) was close to the acceptable limit. The THDv will vary according to the local loads on the supply outside of the control of the site, so there’s a risk this limit could be exceeded at other times of the day. After assessing the panel wiring and earthing, no faults were found in the lift’s setup, confirming that external power quality issues were to blame.

“Once we’d confirmed the issue was external, we focused on mitigating the distortion at the points we could access,” explained Nick Price, team leader — elevator at CP Automation. “We installed a SineTamer sine filter and surge protection device (SPD) at the three-phase input terminals inside the control panel. This allowed us to tackle the problem directly at the source, reducing the impact of electrical noise on the lift system.”

“A SineTamer isn’t just a standard SPD,” continued Price. “It uses frequency attenuation circuitry, meaning it actively tracks and follows the sinewave form, protecting all 360 degrees of it. “After installing the SineTamer, we immediately saw a reduction in the peak voltage distortion,” added Price. “It dropped from 11V at 40kHz, 56kHz and 73kHz to 2.5V at 88kHz — a reduction of around 80%.”

Could SineTamer benefit your site? To find out more about the product and its application, visit the CP Automation website and download product datasheets for free https://www.cpaltd.net/ac-input-products/surge-supressors/surge-protective-devices/