(Middlefield, CT, USA – April 23rd, 2025) — Visitors to CONTROL 2025 in Stuttgart (6–9 May) can expect to see cutting-edge optical metrology in action as ZygoTM, (a business unit of AMETEK, Inc. [NYSE: AME] and a global leader in precision metrology and optical solutions, showcases its some of its range of 3D optical profilers, including the ZeGage™ Pro and the NewView™ 9000, at Booth 9501, Hall 09.

With over five decades of innovation in precision metrology, Zygo is renowned for pushing the boundaries of non-contact surface measurement. CONTROL 2025 is the perfect stage to demonstrate how its technologies are redefining performance benchmarks across manufacturing and R&D environments.

At the heart of Zygo’s exhibition is its world-leading Coherence Scanning Interferometry (CSI) technology. Both the ZeGage Pro and NewView 9000 leverage CSI to deliver fast, non-destructive, sub-nanometer measurements — regardless of surface type. This makes them indispensable tools for industries that rely on surface precision, from semiconductors to optics, automotive, and aerospace.

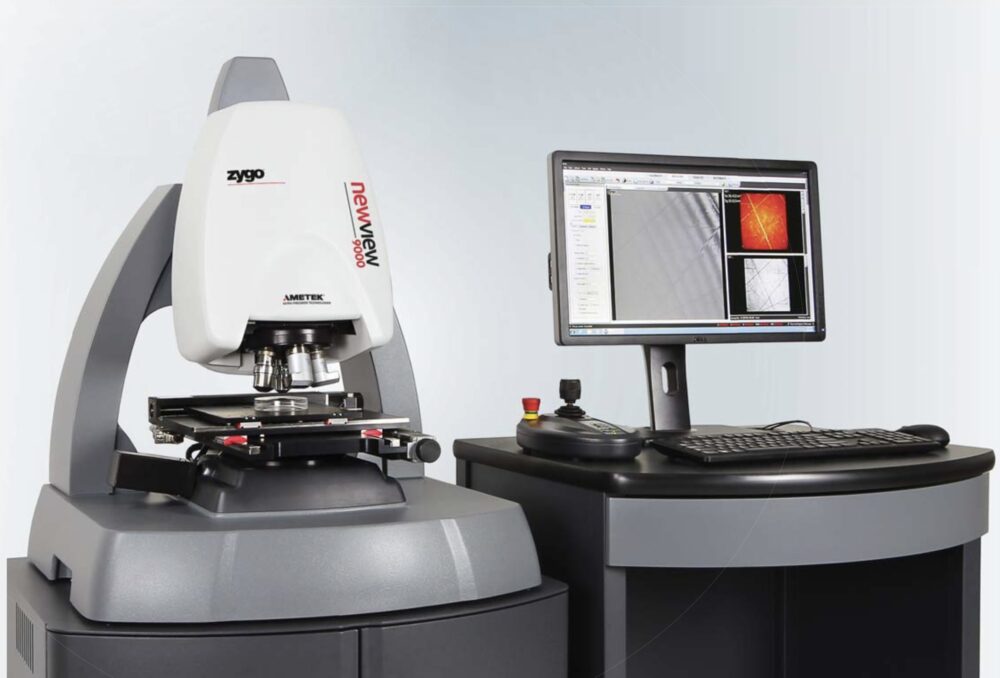

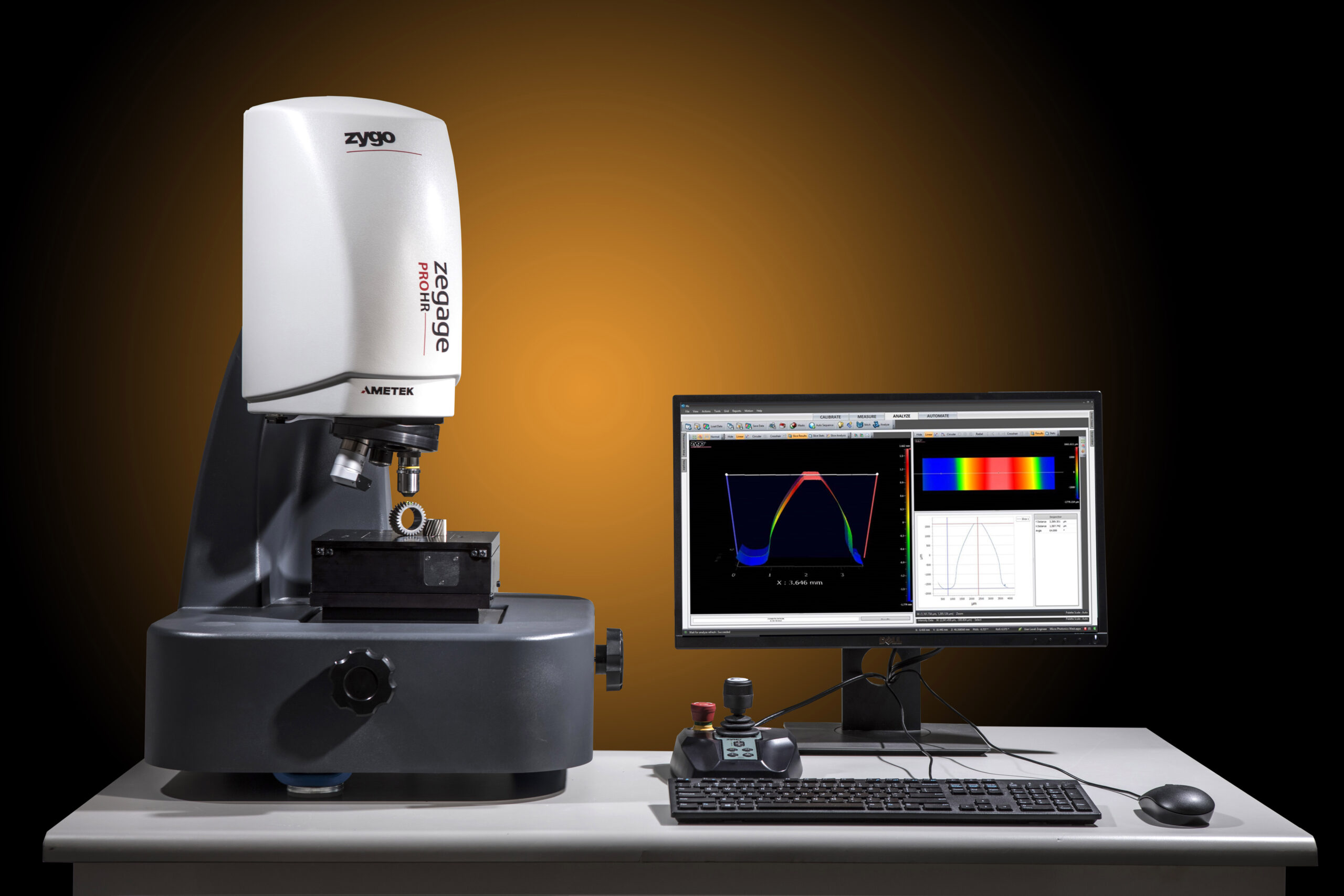

The ZeGage Pro brings Zygo’s world-class optical metrology into a compact, benchtop form factor — ideal for shop floor deployment. It provides comprehensive 3D characterization of micro- and nano-scale surface features, ensuring high-throughput quality control without compromising precision. Meanwhile, the NewView 9000 stands out for its modularity and versatility, capable of analyzing flatness, roughness, thin films, step heights, and more. Visitors to CONTROL will see firsthand how its flexibility — alongside Zygo’s powerful Mx™ software platform — can be tailored to any metrology workflow.

In addition to hardware platforms, Zygo will be highlighting accessory innovations that extend performance and application reach. One standout is the 0.5x ZWF (Zygo Wide Field) objective, purpose-built to accelerate measurements across large areas. With a field of view up to 35mm and a 45mm working distance, this objective is already transforming workflows in sectors like semiconductor inspection, AR waveguide metrology, and large-part precision machining. By significantly reducing stitching requirements, the 0.5x ZWF boosts throughput without compromising accuracy.

“CONTROL is where quality meets innovation,” says Peter Kuschnir, European Sales Manager at Zygo. “We’re excited to showcase how Zygo’s systems combine precision, speed, and usability. Whether you’re inspecting an advanced optical assembly or need in-line process monitoring, we have the right tools and the right team to support you.”

Zygo invites attendees to explore its portfolio, meet with technical experts, and discover how its solutions can optimize production outcomes.