~ How advanced motor design enhances diabetes treatment ~

An estimated 5.6 million people in the UK have diabetes, according to Diabetes UK. For many people, managing the condition involves using a medical pump that pushes insulin into the body. But how do these devices work and why is their design crucial for effective treatment? Here, Dave Walsha, sales and marketing director at brushless motor supplier EMS, investigates.

Medical pumps have transformed the way chronic conditions like diabetes are managed. Insulin pumps provide a consistent and precise delivery of insulin, eliminating the need for multiple daily injections and reducing the risk of complications associated with poorly managed blood sugar levels. These devices use a small motor-driven mechanism to push insulin from a reservoir through a catheter and into the body, typically administered under the skin.

Medical pumps are also used for a variety of other applications, including infusion therapy, pain management and even in wearable drug delivery systems for conditions like Parkinson’s disease. Their ability to deliver controlled amounts of medication over time ensures reliable treatment and minimises the burden of manual dosing, allowing patients to maintain a more comfortable and independent lifestyle.

However, the success of these pumps hinges on the accuracy and consistency of their internal mechanisms.

The driving force behind medical pumps

At the core of each medical pump is a micromotor that powers the mechanical components that regulate the flow of medication or fluids. These tiny but powerful motors are required to provide precise and consistent performance to ensure the pump delivers the correct dose.

For insulin pumps, the performance requirements of micromotors are particularly stringent. Precision is paramount, as even minor inaccuracies could lead to dangerous health conditions such as hyperglycaemia or hypoglycaemia, respectively triggered by under or overdosing. To keep blood sugar levels stable, these motors must deliver insulin in incredibly small increments, often down to a fraction of a microlitre.

Another challenge lies in the size and power requirements of these pumps. Modern insulin pumps are designed to be portable, wearable and discreet, often requiring the entire device to be small enough to fit in a pocket or attach to clothing. For this reason, micromotors used in insulin pumps need to be extremely compact — often with diameters no larger than 10 millimetres (mm). Yet, despite their small size, they must still retain the power and reliability needed for continuous operation.

Advancing treatment with advanced drives

Meeting these demanding performance requirements from such a tiny space is no easy feat, but it is possible with advanced motor technology.

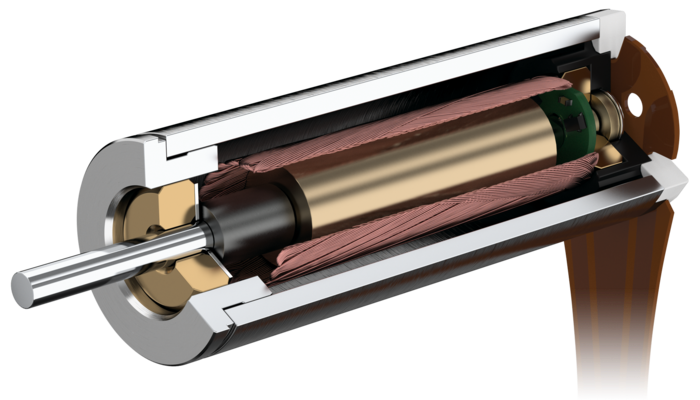

Brushless drives provide the precise speed control required for the frequent start-and-stop motion of insulin pumps. FAULHABER’s brushless DC motors feature advanced two-pole technology to enable smooth and controlled movements. In this design, the rotor features a single magnet with a north and a south pole, housed within an elongated cylindrical shape. This configuration reduces rotational inertia, allowing for faster acceleration and deceleration, which is essential for the precise and responsive adjustments needed to deliver exact increments of insulin.

To address the challenge of tight space constraints, FAULHABER offers a range of micromotors designed for compact applications. The B-Micro brushless DC servomotor is a standout option, with diameters as small as 3 mm and matching gearheads and speed controllers. Despite its miniature size, it delivers exceptional speed control, high efficiency and smooth operation, making it ideal for space-limited applications that require extreme precision.

These motors also operate with cogging-free running, which eliminates perceptible drive-related vibrations and noise. For medical pumps that are often worn continuously, this quiet operation is a must for patient comfort. By combining advanced technology with a focus on user experience, FAULHABER motors are contributing to improved treatment outcomes and patient quality of life.

Micromotors are helping to provide more reliable and patient-centred care by powering compact, quiet-running medical pumps capable of delivering precise doses. As medical pumps become even more powerful and discreet with advanced motor design, these solutions will continue to improve the lives of millions, allowing patients to better manage their health with ease and confidence.

EMS is the sole distributor for FAULHABER in the UK and Ireland. To find out more about how FAULHABER drives could enhance your medical application, visit the website to contact our experienced team.