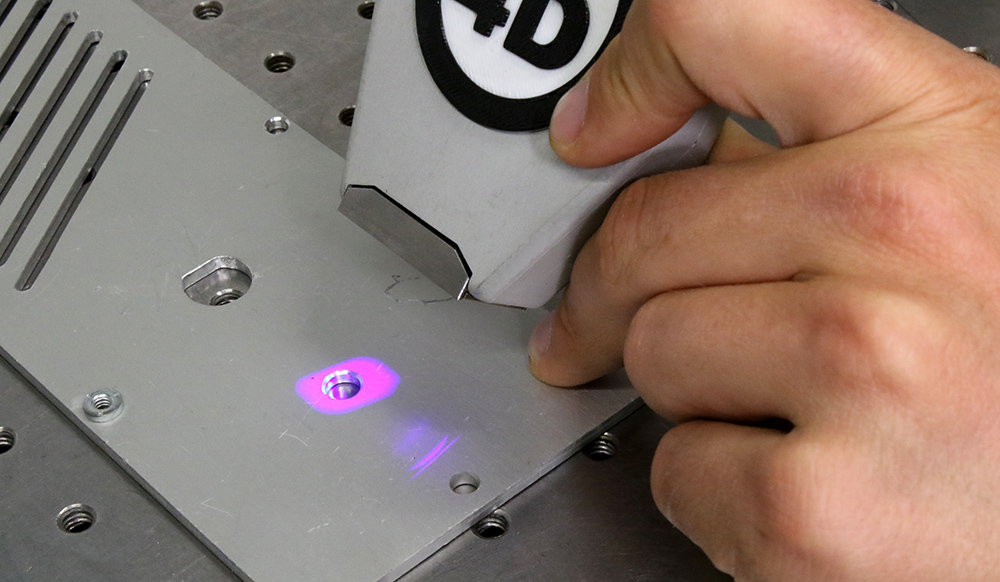

Is your chamfer/Edge break, right? Is it deep enough? Is it aligned to the sides? Are the angles correct? To Determine all this quickly and easily is challenging! Unless you are measuring surfaces in three dimensions. Measuring the planes of left and right sides, with the plane of the chamfer between means you have 3D certainty on the geometries of the part. The new to the UK handheld 4D InSpec from Optimax provides this certainty.

The 4D InSpec Surface Gauge is a pioneering handheld instrument for non-contact measurement of surface features and defects. It offers micrometre-level resolution, portability, and affordability, bringing high-resolution 3D measurement to factory floors and machine shops. It is a vibration-immune 3D surface geometry gauge, and can be used to measure chamfers, rounding and radius on manufactured parts. Because of its speed and precision, it can be used on a robot arm and measure multiple part locations in a rapid routine.

The device also quantifies various surface imperfections, such as pits, scratches, and dents, up to 2.5 mm deep or tall. It surpasses visual comparison techniques in accuracy and repeatability, making it a valuable tool for quality control. The 4D InSpec can be used handheld to access tight corners or large surfaces, and an optional fold mirror allows it to function like a borescope for accessing blind holes.

With its rugged design and versatility, the 4D InSpec is suitable for a wide range of part geometries in challenging environments. It includes user-friendly software that automatically analyses defects and generates detailed 2D and 3D visualizations. The system can be configured for workstation use or mounted on a robotic manipulator for automated measurements, supporting easy data transfer for rapid pass-fail analysis.

4D InSpec is available in the UK and Ireland from Optimax. www.optimaxonline.com

4D InSpec is available in the UK and Ireland from Optimax. www.optimaxonline.com