Event-based vision technology revolutionizes fluid flow analysis, reducing data volume while maintaining high precision—ideal for research, industry, and automation applications.

Today, modern measurement technologies enable high-precision detection of the movement of liquids and gases – and thus provide valuable data for numerous applications. How does the air flow around an aeroplane? How does the blood move through our veins? And how can pollutant emissions in combustion processes be minimised? For this purpose, speed, direction, pressure and turbulence within a flow are analysed in order to increase efficiency, ensure safety and drive innovation in a wide variety of areas.

A range of methods are available to measure these flows, including visual ones such as particle image velocimetry (PIV). High-resolution cameras are used to track marked particles within a flow and analyse their movement. iLA_5150 GmbH from Aachen (Germany) now also relies on EBIV. The abbreviation stands for Event Based Particle Image Velocimetry and is a new optical method for the qualitative and quantitative visualisation of flows and flow velocities. It combines PIV with event-based cameras, here with a uEye EVS from IDS Imaging Development Systems GmbH. The innovative sensor technology of the industrial camera enables highly dynamic and energy-efficient detection, especially of fast and turbulent movements.

Application

In the EBIV method, tiny particles are added to a flowing fluid and illuminated in a plane, the so-called light section plane. They generate individual light pulses as they enter and exit the LED light section. This change in local brightness is recorded independently by the camera pixels and transmitted to the PC as a data stream of “change events”. In contrast to conventional cameras, event-based models therefore only react to the changes in brightness registered in the image field. Stationary scattered light, such as background or a non-changing illuminated surface, does not generate a measurement signal. This reduces the amount of data considerably.

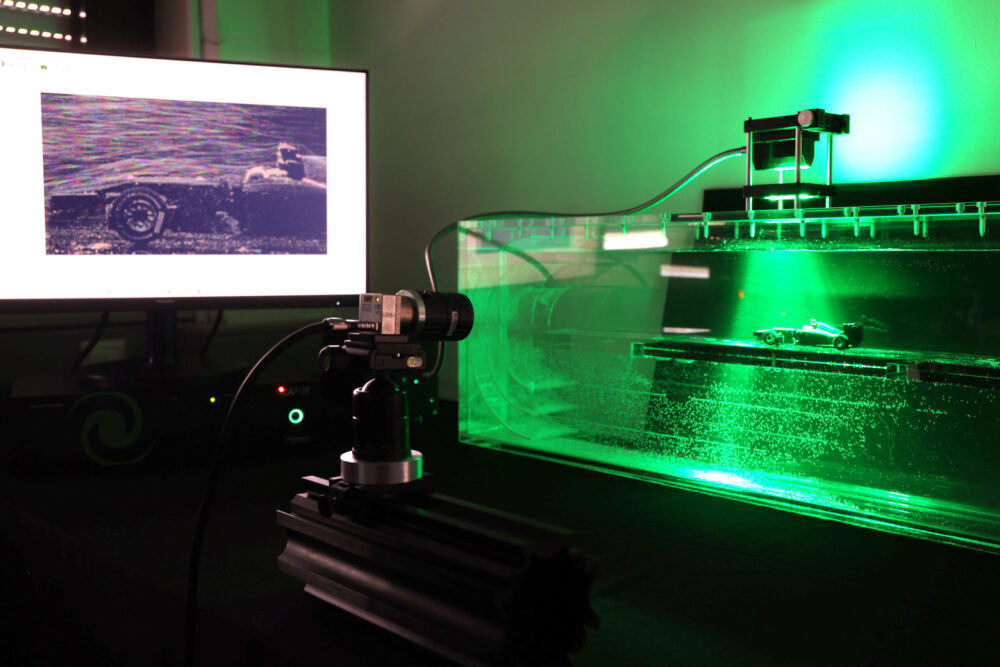

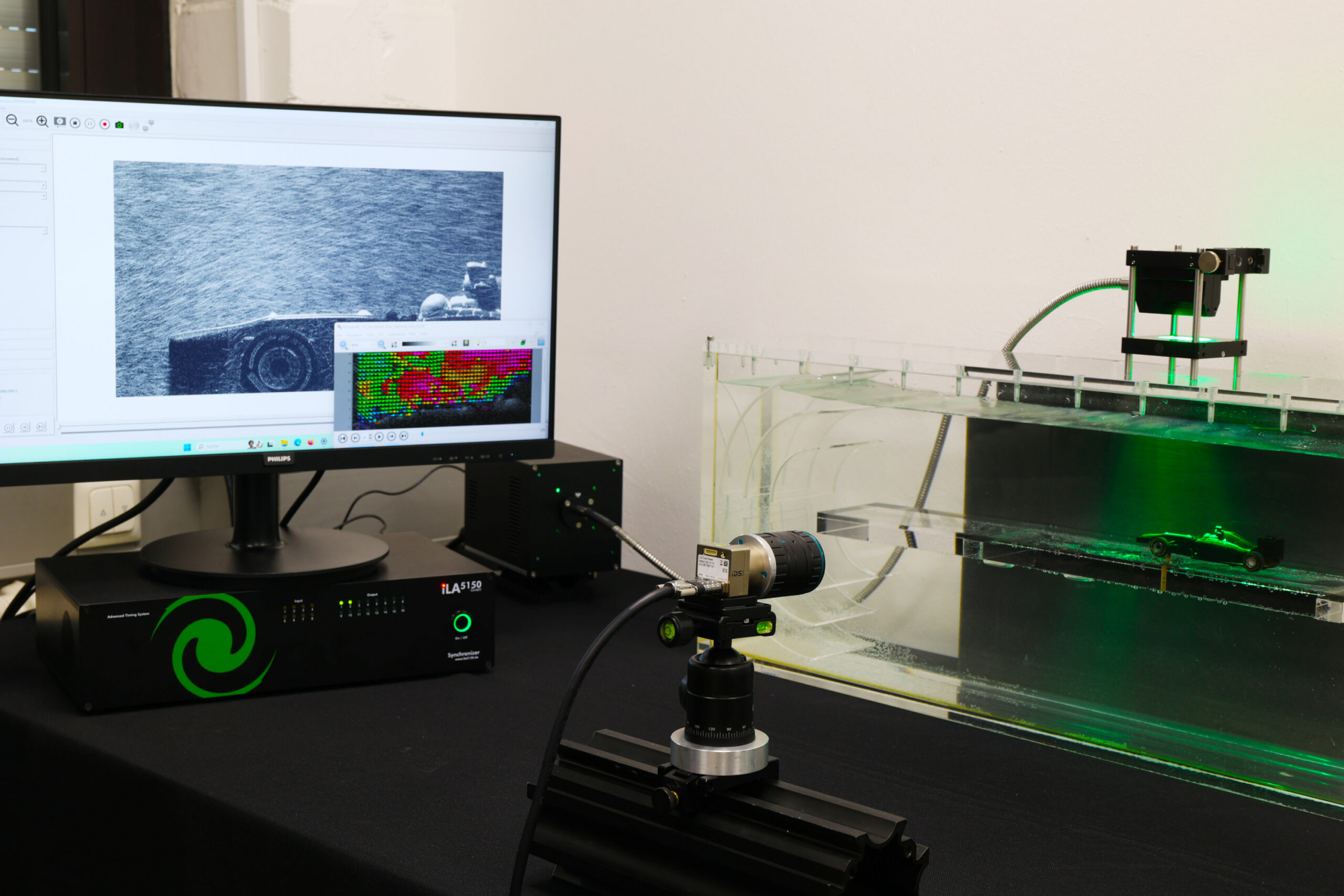

Experimental setup with flow channel, flow model, illumination source, control unit and uEye EVS camera

Frame rates of up to 10,000 frames per second

The data stream essentially contains information about what happens, when and where. In detail, these are the pixel coordinates on the sensor, microsecond time stamps of the pixel events and the information about the events: ON or OFF. This allows a distinction to be made between increasing intensity (ON event) and decreasing intensity (OFF event). Using suitable software, the stream can be converted into an image matrix in which both the spatial information and the linear time base of the stream are available. The result is comparable to the extremely high frame rate of a high-speed camera.

“The EBIV measurement method differs fundamentally from conventional imaging methods. They usually generate very large amounts of data and require powerful peripherals that can process them. For exceptional frame rates of 1000 Hertz and more, the image-based cameras required are themselves very complex and expensive. With the help of event-based camera technology, comparable frame rates of 10,000 frames per second are possible, whereby only standard PC interfaces such as USB with a few gigabits per second are required. The price of the event-based models themselves is significantly lower than that of corresponding high-speed cameras and is therefore also very interesting for smaller teaching and research institutions,” explains Dr André Brunn – Head of Development at iLA_5150 GmbH.

Further processing

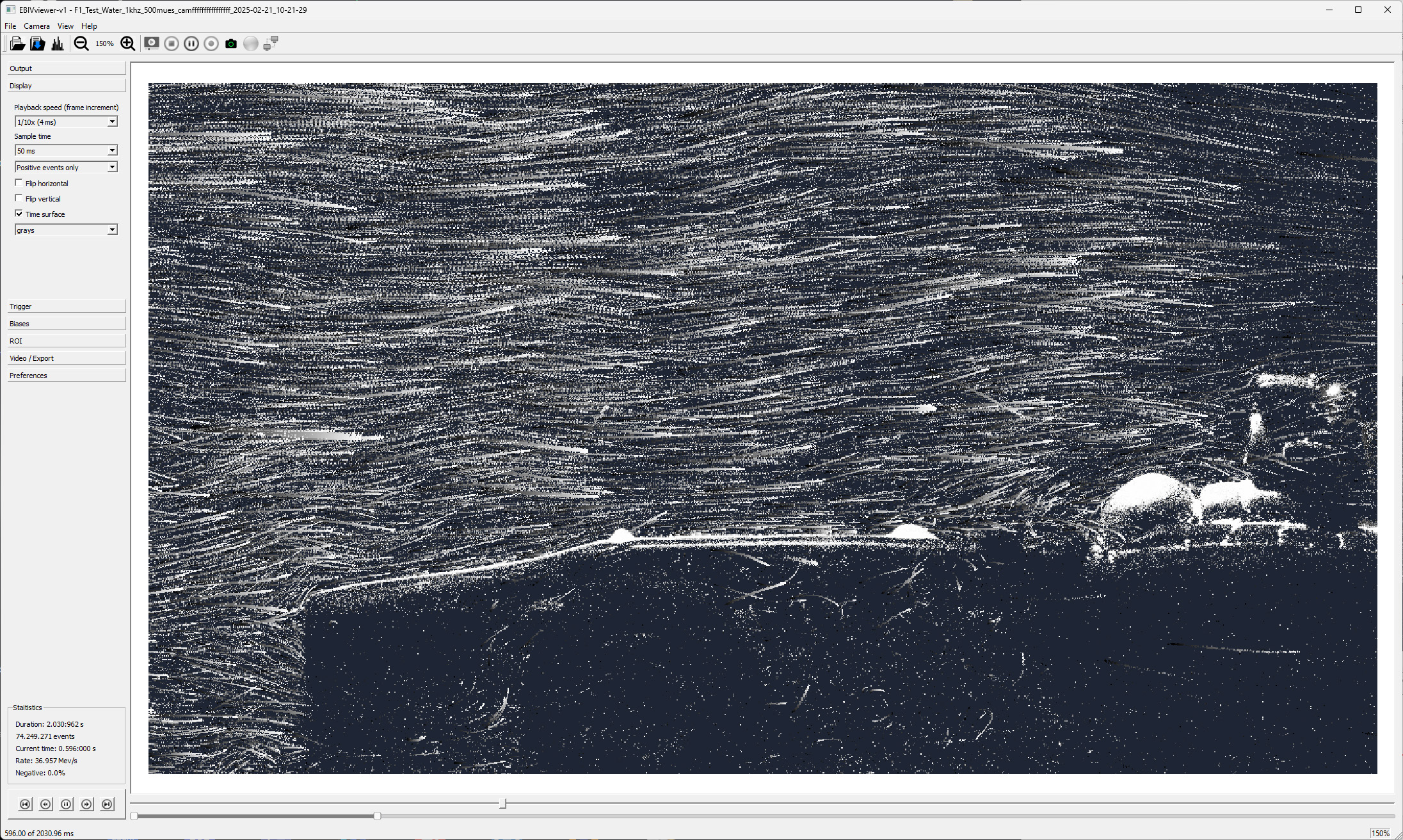

The data stream is converted into image data and displayed in a front end – the so-called EBIV viewer – for direct online flow visualisation. The user can also select the integration time, which corresponds to the exposure time of an image camera, as well as the time increments of the sequence, i.e. the period between two consecutive shots. Classic image filters can also be used. With the help of these settings, the user can optimise the display of the movement paths and adapt them to individual examination objectives. Both fine flow details and large-scale patterns can be made more clearly recognisable. This ability to readjust the measurement results is another advantage of the event-based approach.

In the qualitative visualisation of the flow in the EBIV-View, particles are continuously illuminated so that they are visible as luminous traces. The method is therefore very well suited to visualising the flow. However, it does not provide exact measurements of its speed or direction. For a precise, numerical analysis of the flow properties, individual particles are illuminated for a moment using short, time-defined light pulses.

Flow visualisation in the EBIV viewer

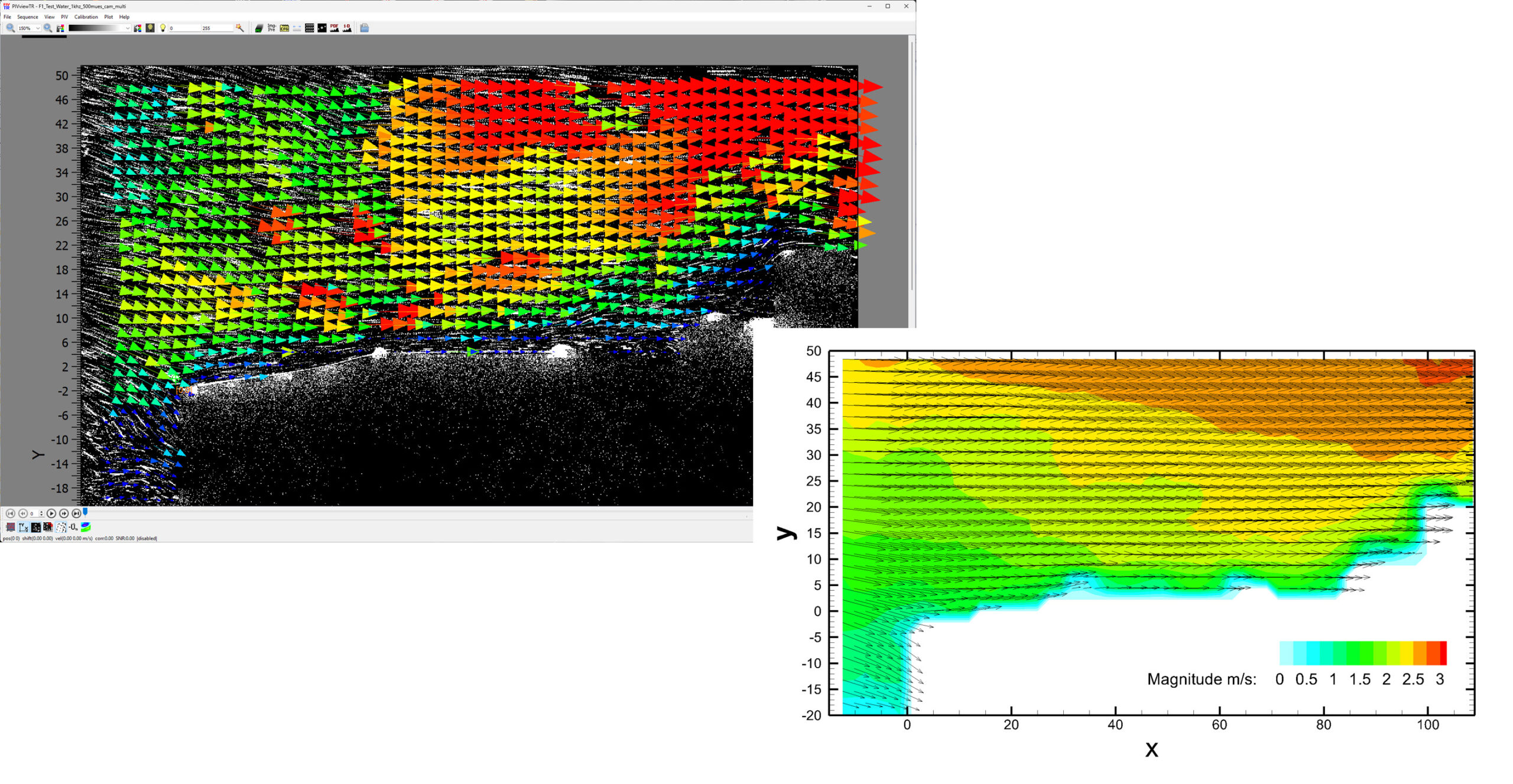

This allows their exact position to be recorded and their movement quantified. By comparing the particle positions in successive images, the speed and direction of the flow can be precisely calculated using PIV, for example. The result is a transient 2D vector field that changes over time – in other words, the vectors do not remain constant. As with classic PIV, the image sequences of the event-based camera can also be statistically analysed, for example to determine mean values and fluctuations in the flow velocity.

PIV-View: Unsteady flow field (left) and time-averaged flow field (right)

On the camera side, iLA relies on a uEye XCP-E from IDS. The small, lightweight industrial camera offers event-based sensor technology in a robust die-cast zinc housing (29 × 29 × 17 mm) with screw-on USB Micro-B connection. It is compatible with all standard C-mount lens sizes. This makes it ideal for both industrial and non-industrial areas. The integrated event-based vision sensor (EVS) was developed by Sony and Prophesee. It is supported by the Metavision SDK, a seamlessly integrated suite of software tools and models, APIs and other training and development resources from Prophesee for efficient analysis, visualisation and customisation.

Building on this, the EBIV viewer from iLA_5150/PIVTec is specially tailored to flow visualisation applications.

Outlook

The optimisation of fluidic systems and processes requires detailed knowledge of the flow conditions. A qualitative flow visualisation is often sufficient to understand effects and develop suitable control mechanisms. Until now, however, imaging fast flows with high temporal resolution was usually only possible with expensive high-speed cameras. Event-based camera technology offers a cost-effective alternative that requires significantly less technical effort. These “simple” methods have been lacking in teaching and research in particular. Thanks to the extreme data reduction, this technology also allows the use of several cameras or large camera arrays without the periphery becoming a limitation for data transfer. The compact design of the uEye EVS models also makes them ideal for mobile applications. This means that real application environments can be analysed directly for the first time – without having to rely on artificial flow models or channels.

In short: Event-based cameras enable efficient, cost-effective and high-resolution visualisation and quantification of flows. Due to the small amounts of data generated, many processes can be analysed almost in real time, which also makes them interesting for use in fully automated systems. Established flow measurement methods such as Particle Image Velocimetry (PIV) can be seamlessly integrated and expanded. The technology can be used wherever flow information is captured by changes in scattered light intensity – be it from moving particles or vibrating surfaces.

Image rights:

iLA_5150 GmbH

© 2025 IDS Imaging Development Systems GmbH

Camera

uEye EVS – industrial cameras

with event-based vision sensor

Model used: uEye XCP-E

Camera family: uEye EVS

Client

ClientLA_5150 GmbH is a system integrator for PIV and other imaging measurement systems. PIV stands for Particle Image Velocimetry – a non-contact optical method for determining velocity fields in fluid mechanics. The company was founded in 1995 as a spin-off from the Technical University of Berlin. It has been creating customised solutions for its customers for almost 30 years. The broad expertise extends across various interdisciplinary areas: Mechanical design, optics, electronics, automation and software development.