FRP at 25 – A Legacy of Engineering Excellence

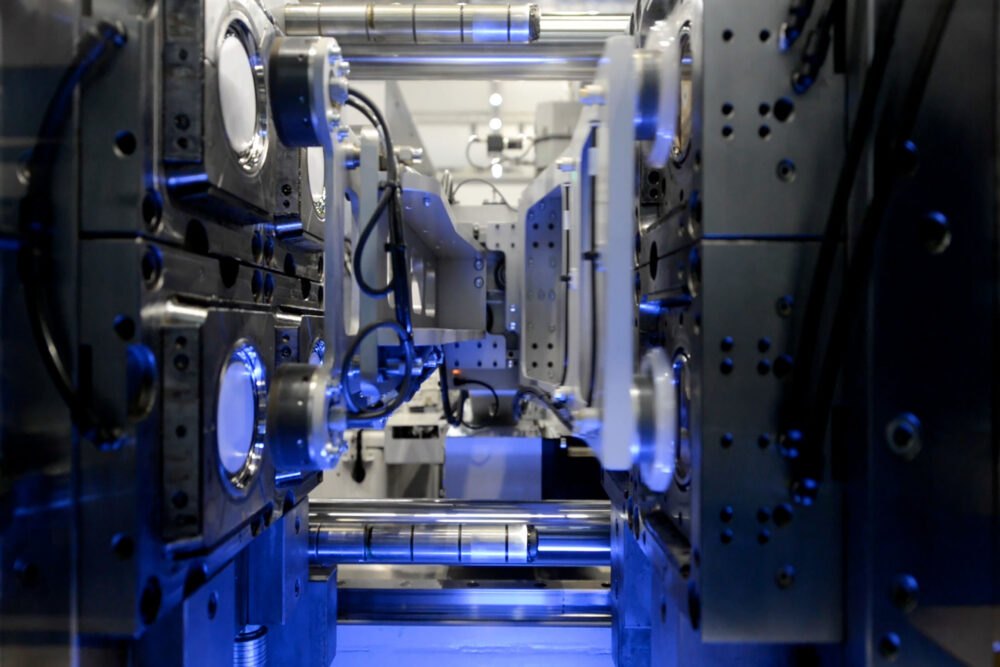

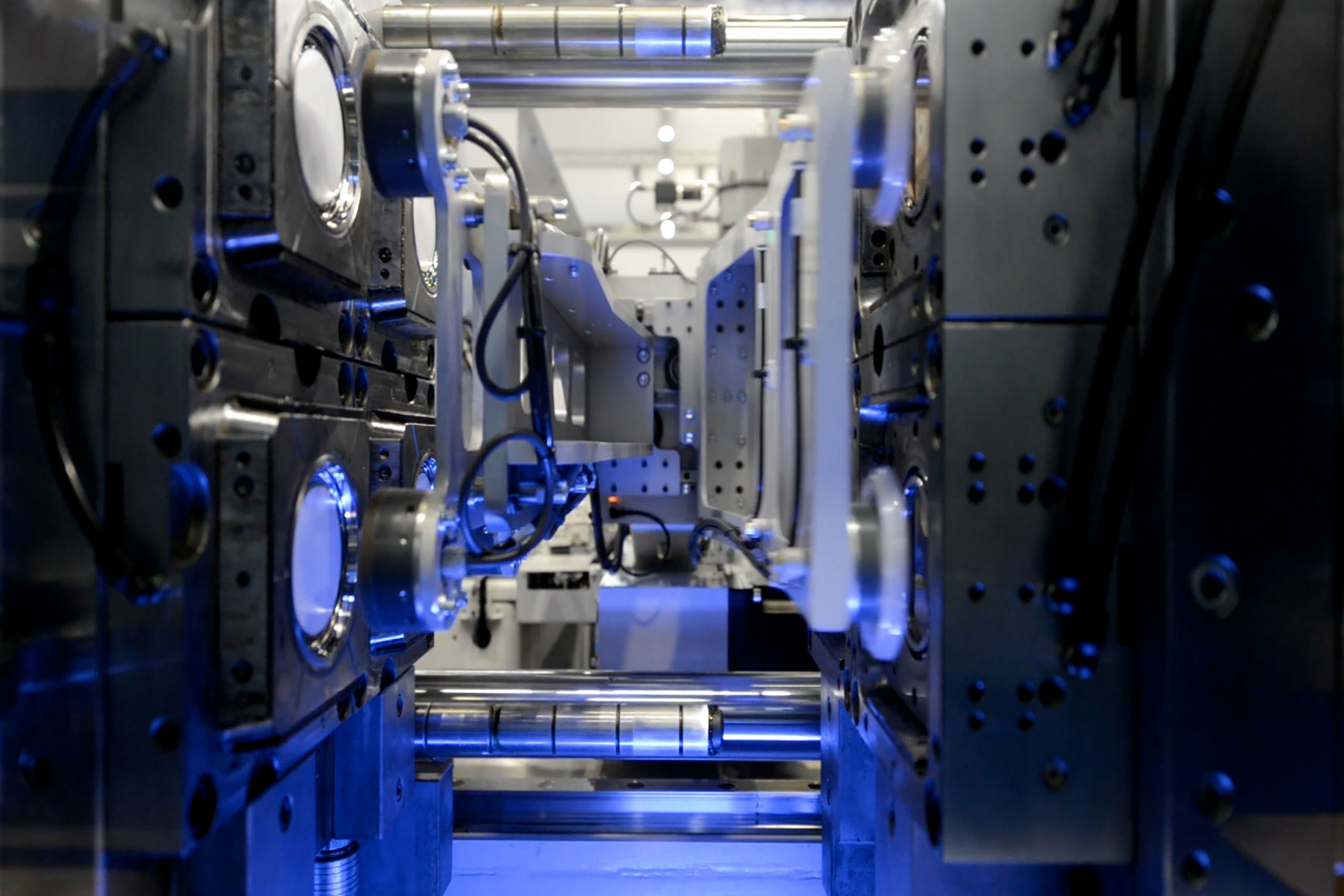

This year, FRP proudly celebrates 25 years of delivering precision engineering and manufacturing solutions. From automotive to medical devices, aerospace, and industrial applications, our expertise in Injection Moulding has helped businesses bring high-quality, scalable products to market.

Why Injection Moulding?

Injection Moulding is one of the most efficient and scalable manufacturing processes, offering high precision, cost-effectiveness, and material versatility. Whether for rapid prototyping or mass production, this process ensures consistency, repeatability, and durability.

FRP’s Injection Moulding Capabilities

Industries We Support

Automotive – Lightweight and durable interior, exterior, and under-the-hood components.

Medical Devices – Precision-moulded sterile and biocompatible components.

Aerospace – High-performance, weight-optimised components for aviation applications.

Industrial – Cost-effective, robust parts for high-demand environments.

For 25 years, FRP has been trusted by leading manufacturers to deliver high-quality injection moulded components with repeatable accuracy and efficiency.

Looking for a reliable Injection Moulding partner?

Celebrating 25 Years of Innovation – Partner with Us Today!

Speak to Our Experts | www.frp.com | sales@frp.com | 01945 411 700 | 01926 335 680