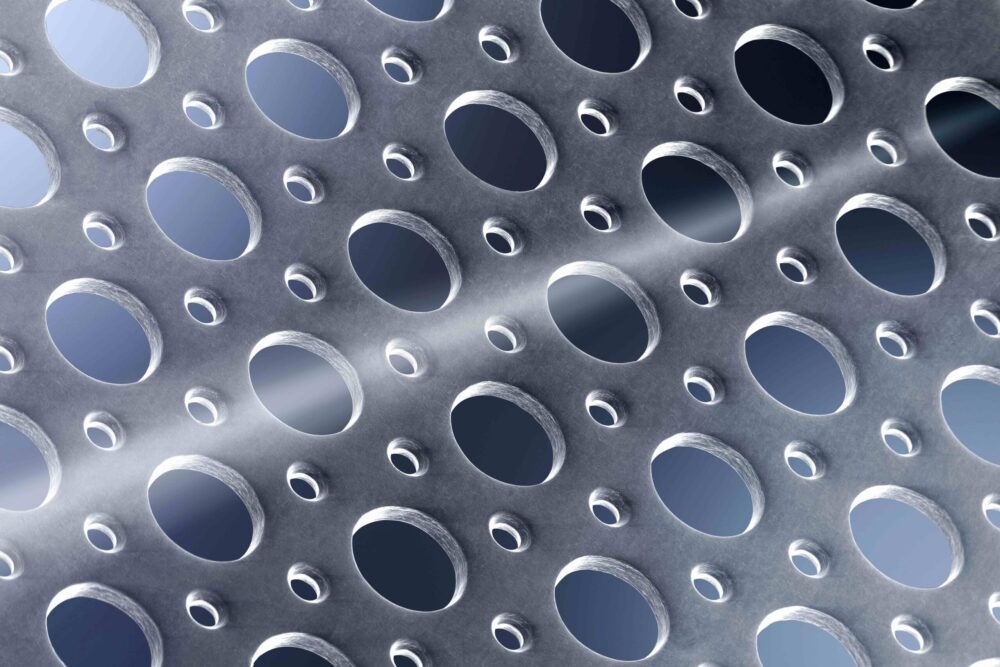

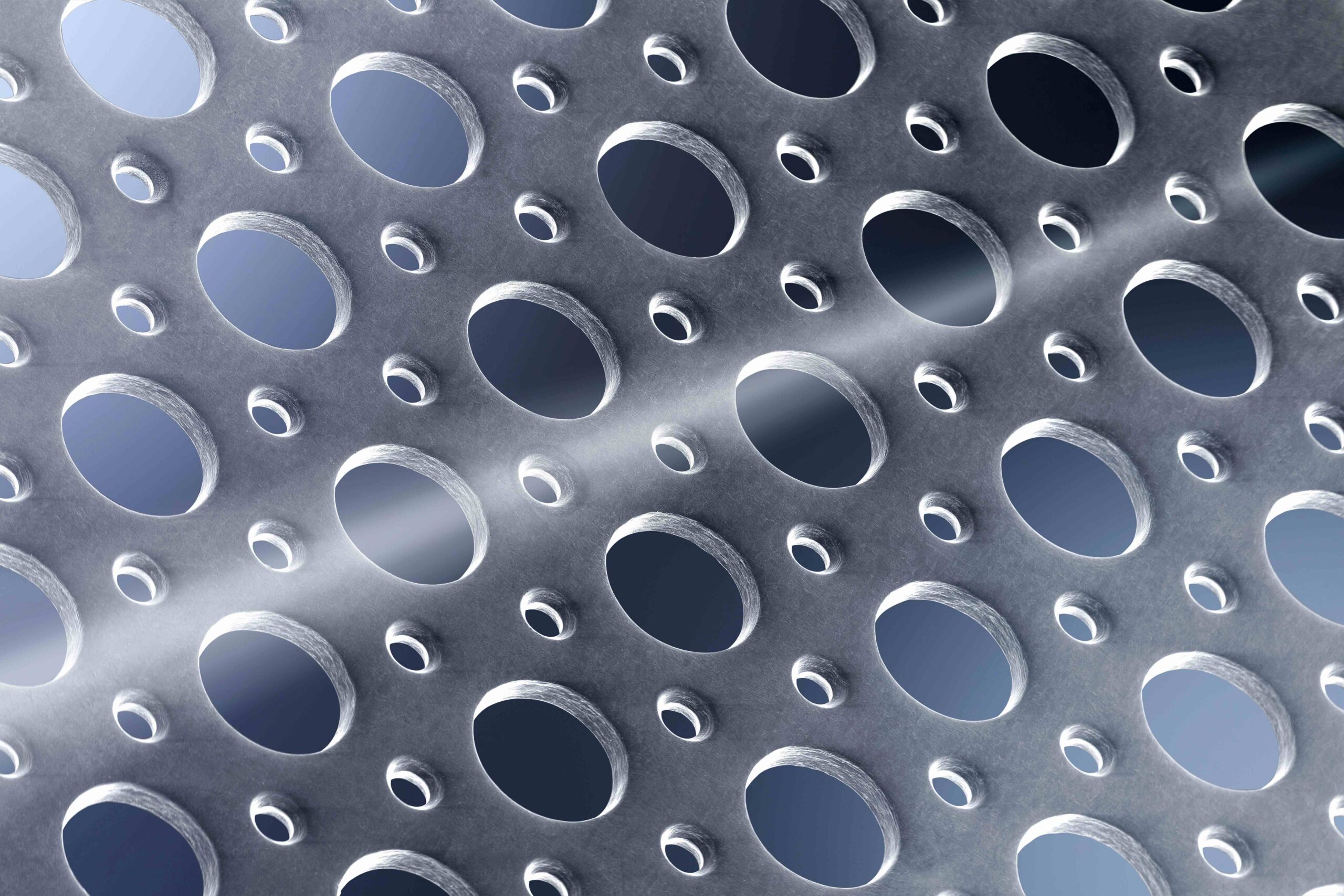

Today, speed, precision, and adaptability define market leaders, and manufacturers can no longer afford rigid production processes. Industries are evolving faster than ever, demanding custom solutions that push the boundaries of design and performance. At micrometal Group, the company understands that every customer has unique requirements — and it has built its photo-chemical etching (PCE) process to be as flexible as the industries it serve.

Manufacturers across medical, automotive, aerospace, and electronics sectors are under pressure to innovate, reduce lead times, and optimise costs. Traditional machining techniques often impose design constraints, increase production costs, and limit scalability. micrometal Group breaks these barriers by offering a production process that is adaptable, scalable, and cost-effective — without compromising on precision.

“Flexibility is no longer a luxury, it’s a necessity,” says Jochen Kern, Head of Sales & Marketing at micrometal Group. “Our customers come to us with highly specific demands — complex geometries, ultra-thin materials, or rapid scale-up requirements. Thanks to our advanced PCE process, we deliver exactly what they need, with unmatched accuracy and consistency.”

Unlike traditional manufacturing, which often requires expensive retooling or time-consuming modifications, micrometal Group’s photo-chemical etching process allows the company to rapidly adjust designs with minimal disruption. This means faster design iterations with no need for complex retooling, allowing the company to make design adjustments quickly and efficiently. Micrometal Group’s scalable production ensures that whether it’s a small prototype run or mass production, its process adapts to customer needs. The company also offers material versatility, working with a variety of metals, including stainless steel, titanium, and copper alloys, giving customers flexibility in material selection. This ability to adapt and scale seamlessly is why micrometal Group has become a trusted partner for precision-driven industries worldwide.

Kern continues, “Industries today are not only focused on precision but also on sustainability, cost-efficiency, and rapid innovation cycles. micrometal Group’s PCE process meets these demands head-on by reducing material waste, eliminating costly tooling, and accelerating time to market. Our approach is simple — give customers the freedom to innovate without restrictions. We are not just a supplier, we are a solutions provider. Our goal is to make our customers’ production process more efficient, flexible, and future-ready.”

Customers don’t just need precision, they need a manufacturing partner that understands their challenges and can provide solutions tailored to their needs. micrometal Group’s expertise, coupled with its flexible production model, makes the company the ideal choice for manufacturers looking to stay ahead of the curve. For companies seeking scalability, customisation, and precision, micrometal Group delivers solutions that make innovation a reality.

Ready to take production to the next level? Contact micrometal Group today and discover how flexible manufacturing can transform your business.