~ Beckhoff introduces new range of cost-effective automation solutions ~

Industrial automation expert, Beckhoff, has expanded its offering by introducing a range of cost-effective motion control products. For companies operating on a tighter budget and without the need for ultra-high accuracy, Beckhoff’s new economy range of motion control solutions can offer a balance between performance and affordability.

In some motion control situations, customers prioritise speed and acceleration over extreme levels of accuracy. On a mover’s return path, for example, there are no process stations, and the primary concern is getting the mover back as quickly as possible.

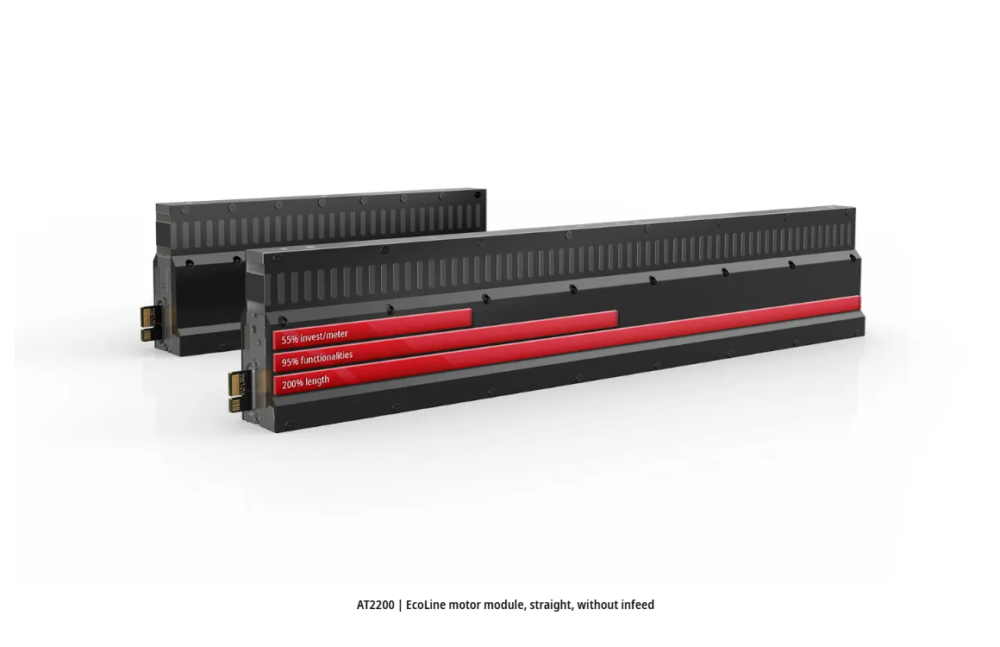

Beckhoff’s eXtended Transport System (XTS) is an advanced linear transport solution that uses magnetically-driven movers travelling along customisable paths formed by integrated motor modules. Controlled via an industrial PC running TwinCAT automation software, each mover operates independently, allowing for tailored motion profiles.

The new XTS EcoLine modules deliver 95 per cent of the technical capabilities of the well-known standard modules at 55 per cent of the cost for the same distance. The new modules support travel speeds up to 4 m/s, accelerations up to 10 g and payloads up to 10 kg, with an absolute accuracy of 0.70 mm and repeatability of 0.075 mm. They are fully compatible with standard motor modules, making them versatile for various applications, especially where ultra-high precision is not critical.

Beckhoff has also optimised the functionality of its drive solutions to produce the AF1000 economy variable frequency drive (VFD) and AX1000 economy servo drive.

“All of the well-known features of the AX5000 or AX8000 are available in the AX1000 and AF1000 units, just not at 100 per cent of their capability,” said Mark Richards, UK sales manager at Beckhoff. “Some customers just don’t need that level of performance, so by reducing it we can offer a highly cost-effective drive, without compromising on quality.”

The AF1000 is a compact, cost-effective solution tailored for fundamental drive applications such as pumps, fans and belt drives. By prioritising essential features and eliminating unnecessary complexity, the AF1000 delivers reliable performance at a competitive price, making it ideal for applications where ultra-high precision is not required.

Designed for ease of integration, the AF1000 connects seamlessly with the TwinCAT system via EtherCAT for straightforward commissioning and diagnostics. It also features optional drive-integrated safety functions such as Safe Torque Off (STO) and Safe Stop 1 (SS1), along with up to six digital I/Os and the ability to connect external ballast resistors.

Another new cost-effective development is the Beckhoff AX1000 economy servo drive. Designed to provide a solution for dynamic positioning tasks while maintaining high technological standards, it is available in either single-phase or three-phase.

“This is an optimised product with fewer external components,” said Richards. “For example, we don’t need a 24 V plug anymore because we produce 24 V with the internal DC link voltage, and we use the internal 24 I to feed the I/Os and the motor brake. That means customers don’t need an external power supply or the space it takes up in the cabinet.”

AX1000 supports various motor types, including AM8000 synchronous servomotors with One Cable Technology (OCT), as well as asynchronous and reluctance motors. The series is also fully integrated into the TwinCAT system via EtherCAT, facilitating straightforward commissioning, operation and diagnostics.

Products like the XTS EcoLine, AX1000 servo drives and AF1000 variable frequency drives are specifically designed to optimise precision and functionality for cost-sensitive applications. By optimising performance and focussing on fit-for-purpose capabilities, these solutions enable businesses to achieve reliable results, streamline operations and enhance efficiency, while minimising capital investment.

For more information on how Beckhoff’s economy options can provide access to high-quality technology tailored to your company’s budgetary requirements, visit www.Beckhoff.com/Motion.