Combining SEM and XPS for chemical and structural understanding

Eindhoven, The Netherlands (December 2024) — In the development and analysis of advanced materials, the interplay between surface chemistry and structural properties is essential for understanding material behaviour. However, since several different methods — such as scanning electron microscopy (SEM) and X-ray photoelectron spectroscopy (XPS) — may need to be used, ensuring that data is obtained from the same regions of interest is vital. Here, Christopher Deeks, Channel Manager XPS at Thermo Fisher Scientific, explores how implementing a Correlative Imaging and Surface Analysis (CISA) workflow offers materials scientists an efficient and comprehensive method of tackling this challenge.

Nanostructured materials are designed with complex properties that stem from both their chemical composition and their structural design, making their behaviour vastly different to other materials. Depending on the application, these properties might include mechanical strength, corrosion resistance, conductivity, biocompatibility or thermal stability. For instance, a nanoengineered material used for a battery electrode may exhibit a greater surface area to improve its energy storage capacity and enhanced electrical conductivity to limit energy loss.

These complexities are exacerbated when you consider how materials perform under operational conditions, where both chemical reactivity and structural integrity must be assessed since minor changes at the nanoscale can influence performance. To truly understand how material properties perform, it’s essential to integrate both structural and chemical information.

The standard approaches of SEM and XPS each offer unique insights into material behaviour but are limited when used independently. SEM provides high-resolution images of surface and structural features but cannot probe the crucial chemical differences in the topmost atomic layers. XPS, with its surface sensitivity, excels in analysing these ultrathin films (0–10 nm), identifying elemental composition, chemical states and bonding potential. This capability is vital since surface atoms are not surrounded by other atoms on all sides, meaning they often exhibit higher reactivity than the bulk material, which influences the material properties.

Solving challenges with CISA

The CISA workflow by Thermo Fisher Scientific addresses these gaps by enabling the combination of SEM and XPS data in a seamless and synchronised way. With this integrated workflow, material scientists can achieve a comprehensive understanding of both the structural and chemical aspects of materials, which provides insights critical for development, quality control and regulatory approvals.

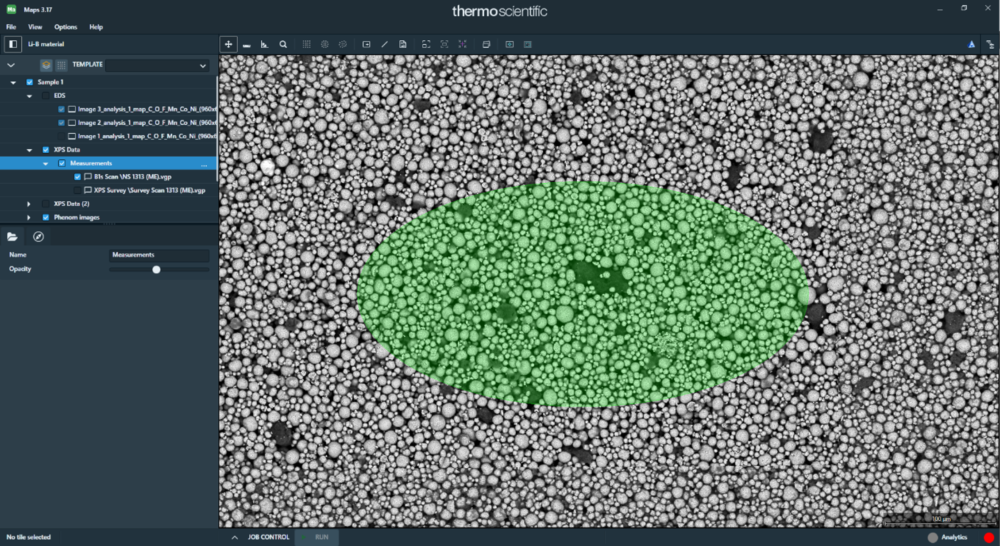

The process begins with mounting the sample on a specialised holder with fiducial marks that preserves the alignment of the sample during transfer between SEM and XPS systems. By facilitating region of interest (ROI) sampling, the workflow ensures that both chemical and structural data are from the same area, allowing for accurate correlation between the two.

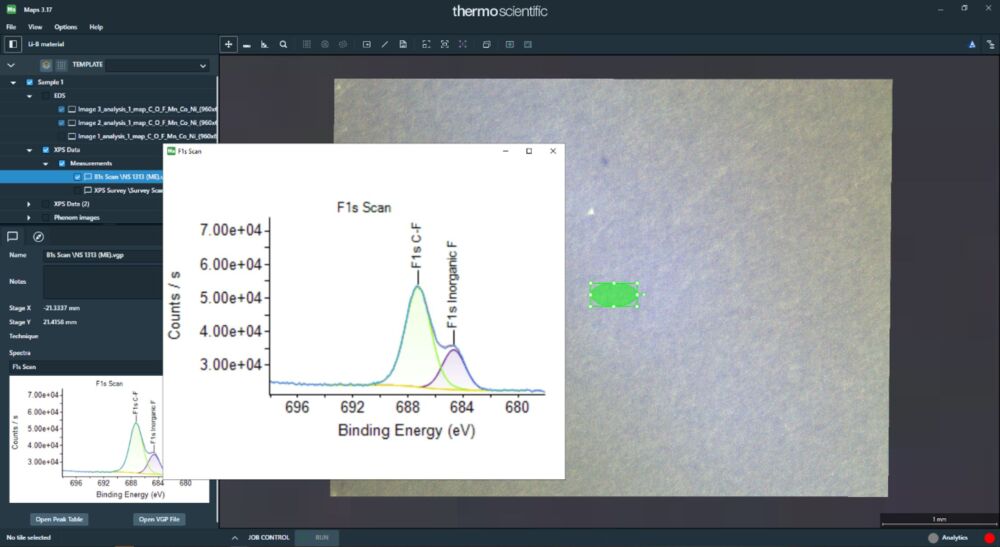

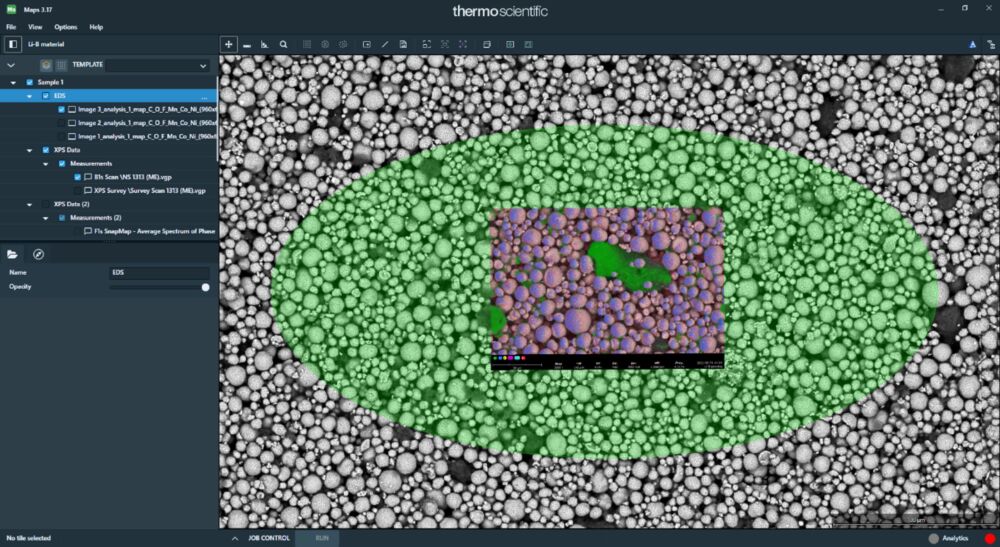

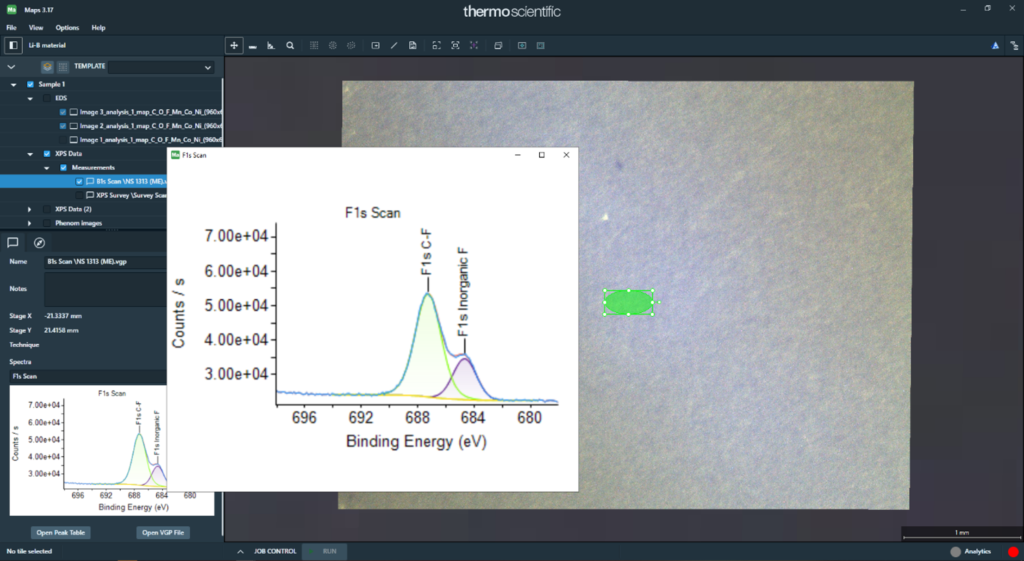

Typically, the XPS analysis is carried out first, with users benefiting from the Thermo Scientific Avantage software, which integrates instrument control, data acquisition, data processing and reporting for improved precision and accuracy. When the SEM analysis is carried out, Thermo Scientific ChemiSEM technology enables high-throughput chemical analysis with energy-dispersive X-ray spectroscopy (EDS) mapping. This provides materials scientists with a thorough overview of the composition of hundreds of inclusions in a matter of hours.

Thermo Scientific Maps Software further enhances the process by correlating SEM and XPS data in an automated and user-friendly platform.

This workflow facilitates more reliable analysis with the ability to visualise surface morphology while simultaneously examining the chemical state of surface elements, even at the atomic level. By doing so, it overcomes the limitations of using SEM or XPS in isolation and allows researchers to create a more complete picture of a material’s behaviour.

Use cases in focus

CISA can help researchers understand how the properties of materials used for applications such as coatings, lithium-ion batteries and antimicrobial fabrics may perform under real-world conditions.

For example, a growing area of research in healthcare materials looks at improving the characteristics of medical textiles, including stain resistance, water repellence, reduced flammability and antimicrobial properties. These fabrics are used in everything from personal protective equipment (PPE) to implantable applications such as surgical sutures and artificial joints. When it comes to increasing textiles’ antimicrobial properties, both integrating nanoparticles and applying coatings are common.

By using the CISA workflow, researchers can effectively examine the uniformity of nanoparticle distribution of the ROI through SEM and analyse the chemical state of the nanoparticles using XPS. This integrated approach enables precise correlation between structural features and surface chemistry, facilitating improvements in nanoparticle attachment, surface functionalisation and overall material performance. This ensures the textiles are safe, effective and suitable for critical medical applications.

Another use case is in the battery industry, where researchers often need to examine how electrode materials change over time, but struggle to ensure that similar areas are being analysed. Using XPS allows researchers to track chemical states during cycling, but the grain structure and compound locations are not visible until the sample is transferred to the SEM. Therefore, the CISA workflow means researchers can gain a comprehensive understanding of material degradation, which helps in developing more durable and efficient battery components.

When analysing complex materials at the nanoscale, ensuring that the same area of the sample is assessed during SEM and XPS analysis often poses a challenge. However, the advent of the CISA workflow enables material scientists to gain a complete, accurate understanding of material properties, helping improve performance and boost innovation in applications such as medical devices, coatings and energy storage.

To find out more about how a CISA workflow could support your materials application, get in touch with our expert team.