Brett Saddoris, Technical Marketing Manager, Accumold

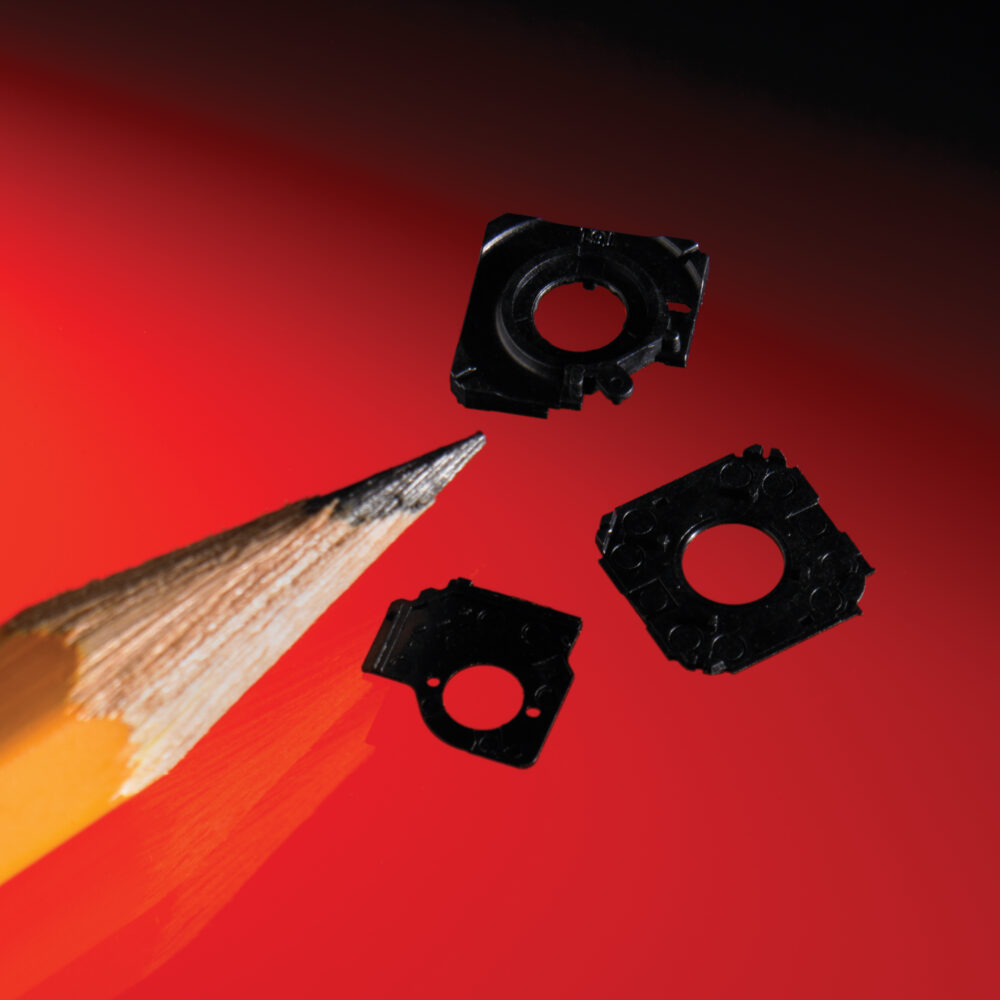

As industries continue to innovate and develop smaller, more complex products, micro molding has become a vital technology for delivering high-precision components. From medical devices and telecommunications to consumer electronics and automotive applications, the demand for micro-molded parts is accelerating. Yet, as this demand grows, so does the complexity of supply chain management. For companies that depend on micro molding, one of the most critical decisions they face is choosing the right manufacturing partner, a decision that can profoundly impact not just current projects but also the long-term viability of their operations.

Partnering with a micro molding supplier is more than a short-term arrangement to meet immediate production needs, it’s a strategic investment in the future of your business. By selecting a partner with the right combination of capabilities, scalability, and sustainability, companies can effectively future-proof their supply chain, avoiding the risks and inefficiencies that come with supplier transitions. For leading micro molding specialist Accumold, this approach forms the cornerstone of its value proposition, ensuring that customers have the confidence and flexibility to navigate evolving market demands with a trusted partner at their side.

THE LONG-TERM IMPLICATIONS OF PARTNERING DECISIONS

The decision to work with a micro molding partner extends far beyond the technical ability to produce small, precise parts. While many suppliers can meet the baseline requirements of micro molding, only a select few can deliver the combination of capabilities, operational scale, and financial stability required to grow alongside their customers. For businesses operating in industries with dynamic and fast-changing needs, this distinction is crucial.

If a supplier lacks the capacity to accommodate scaling production demands, customers may face significant disruptions, delays, and additional costs. Changing suppliers midstream — particularly when dealing with complex micro-molded components — is fraught with challenges. Tooling may need to be redeveloped, processes revalidated, and designs re-optimized to meet the standards of a new supplier. This not only introduces risks to the continuity of supply, but can also compromise quality and delay product timelines. The hidden costs of such a transition can far outweigh any perceived savings from initially choosing a less robust partner.

By contrast, choosing a partner that combines capability, scalability, and sustainability ensures that businesses can remain with a single supplier for the life of their products, enjoying seamless support and consistent performance. This future-proofing of supply chains offers significant strategic advantages, from reducing risk to streamlining operations and accelerating innovation.

THE ADVANTAGES OF A LONG-TERM PARTNERSHIP

The benefits of selecting the right micro molding partner extend far beyond cost savings. A long-term partnership with a supplier like Accumold delivers unique advantages that enhance operational efficiency, minimize risk, and ensure success even as requirements evolve.

Continuity of Supply. One of the most significant risks in micro molding is the potential for supply chain disruption. A partner with robust scalability and a proven track record of reliability can ensure continuity of supply even as production volumes grow or market demands shift. Accumold’s vertically integrated operations and extensive infrastructure provide customers with the confidence that their needs will be met, regardless of scale. Whether producing tens of thousands or millions of parts, Accumold’s capacity to scale ensures that customers are never left searching for alternative solutions.

Quality Consistency. When working with micro-molded components, maintaining quality and precision across production volumes is non-negotiable. Shifting to a new supplier often introduces variability as tooling, processes, and validation procedures must be adjusted. In contrast, a long-term partner like Accumold ensures consistency by maintaining a deep understanding of each customer’s requirements and investing in robust quality control systems. By keeping all critical processes in-house — from tooling to metrology — Accumold can guarantee precision and reliability, even as production volumes increase.

Faster Time to Market. In dynamic industries, speed is often a critical competitive advantage. Transitioning between suppliers can cause significant delays due to the need for retooling, revalidation, and process optimization. A long-term partnership eliminates these delays, allowing customers to move quickly from prototyping to full-scale production. Accumold’s vertically integrated operations and expertise in design for micro molding (DfMM) further accelerate time to market, ensuring that customers can respond rapidly to emerging opportunities.

Streamlined Operations. Managing multiple suppliers can be both time-consuming and costly. Each supplier relationship requires coordination, communication, and oversight, increasing the complexity of supply chain management. By partnering with a single supplier that can accommodate both current and future needs, customers can streamline operations and reduce administrative overhead. Accumold’s ability to handle everything from initial design consultation to high-volume production simplifies the entire process, enabling customers to focus on their core business.

Access to Innovation. Innovation is at the heart of industries that rely on micro molding, and a long-term partnership with the right supplier ensures access to the latest technologies and capabilities. Accumold’s commitment to continuous improvement and investment in emerging technologies, such as micro additive manufacturing (micro AM), means that customers can take advantage of new opportunities as they arise. By staying at the cutting edge of the industry, Accumold helps its customers remain competitive in rapidly evolving markets.

DAVID W. HOFFA

THE RISKS OF CHANGING SUPPLIERS

While the advantages of a long-term partnership are clear, the risks of switching suppliers mid-project — or mid-product lifecycle — underscore the importance of making the right decision from the outset. Changing suppliers introduces numerous challenges, including technical, logistical, and financial obstacles that can disrupt operations and compromise product quality.

One of the most immediate challenges is the need to transfer tooling and revalidate processes. Tooling developed by one supplier may not be compatible with another’s equipment or methods, requiring costly modifications or complete redevelopment. Additionally, revalidating processes to ensure compliance with quality standards and regulatory requirements can be time-consuming and expensive.

Another risk is the loss of institutional knowledge. Over time, a trusted supplier develops a deep understanding of a customer’s unique needs, preferences, and specifications. This knowledge allows them to provide proactive support, anticipate potential issues, and deliver tailored solutions. A new supplier must start from scratch, often leading to a steep learning curve and a higher likelihood of errors or miscommunications.

Finally, changing suppliers can strain internal resources. Managing the transition requires significant time and effort from engineering, procurement, and quality teams, diverting attention from other critical priorities. For companies operating in fast-paced industries, these distractions can hinder their ability to respond to market demands and innovate effectively.

FUTURE-PROOFING THROUGH PARTNERSHIP

In the rapidly evolving world of micro molding, the ability to adapt and grow is essential. For companies that depend on precision components, choosing the right partner is not just about meeting today’s requirements, it’s about securing their ability to meet tomorrow’s challenges. By selecting a partner like Accumold, with the capability, scalability, and sustainability to support long-term success, businesses can future-proof their supply chains, avoid costly disruptions, and position themselves for sustained growth.

The decision to partner with a micro molding expert is a pivotal one. With Accumold, companies gain more than just a supplier, they gain a partner that is committed to their success, capable of meeting their needs today, and ready to support their ambitions for the future.