~ Exploring how remote monitoring systems improve safety, efficiency and compliance in multi-point lifting operations across industries ~

Since the dawn of industry, multipoint lifting operations have been used to lift large, heavy loads in challenging environments. From hoisting construction materials to loading containers, these complex, hazardous operations demand innovative solutions. Here, Steve Hosgood, senior sales executive at real-time data monitoring expert Mantracourt, explores how remote monitoring systems are addressing challenges in multi-point lifting operations and enabling safer, more productive workflows.

Multi-point lifting operations face unique challenges across industries. In offshore wind farm construction, underhook monitoring ensures that heavy components are lifted safely and accurately, reducing the risk of accidents. Similarly, in mining operations, load monitoring systems protect workers by preventing overloads and ensuring balanced lifts.

The construction industry exemplifies the safety concerns inherent in multi-point lifting operations. According to Health and Safety Executive (HSE), in the 2023/24 reporting year, there were 51 fatal injuries to construction workers in Great Britain, the highest among all industry sectors.

This marks a staggering 70 per cent increase since 2018/2019, underscoring the sector’s ongoing safety challenges. Risks such as load imbalances, equipment overloads, and hazardous environments must be addressed to reduce these statistics.

One way to monitor and assess the risks during lifting operations is through sensors. Sensors like load cells are used to provide insights into the total load and weight distribution of objects being lifted. Uneven loads, in particular, can introduce unpredictability and stress points, increasing the risk of accidents if not managed effectively.

Operators can connect to the sensors either through a wired connection or by using wireless transmitters connected to a network and monitored on multiple devices remotely. Through delivering real-time data, these sensor setups enable operators to monitor and adjust lifting operations dynamically, helping them assess risks before they develop into incidents.

Wired vs. wireless monitoring

While both wired and wireless telemetry systems can allow for real-time monitoring to detect issues like overloads or underloads, wireless systems offer significant advantages. Unlike wired setups, which require extensive cabling and fixed installations, wireless systems are more flexible and easier to deploy, particularly in complex or large-scale environments. They reduce installation time, minimise tripping hazards associated with cables, and offer greater mobility for operators who need to monitor data from multiple locations.

Wireless systems may also enable cloud-based remote monitoring, giving operators access to live and historical data from any location.

And it’s not just about efficiency and ease of use. There is a significant safety benefit to using a wireless system over a wired setup. Wireless systems reduce the need for workers to approach hazardous equipment, enhancing safety during installation, readings or calibrations.

Imagine a construction site where a crane is lifting heavy building materials for a high-rise project. As the load is hoisted, sensors detect a slight imbalance, and an alert is instantly sent to the operator in the crane via a handheld device.

Simultaneously, the site supervisor receives the same alert on their device, while the project manager monitoring remotely is notified via a cloud-based platform. This coordinated flow of real-time information ensures that adjustments can be made immediately, preventing potential accidents and ensuring the operation runs smoothly.

The importance of regulatory compliance

Adherence to safety standards is vital in hazardous industries like construction and offshore energy. HSE continues to monitor workplace fatalities, underscoring the need for stringent compliance with safety regulations. Real-time data systems play a critical role in achieving compliance by providing accurate monitoring and immediate alerts, ensuring safety and efficiency in lifting operations as well as reducing the need to put workers in harm’s way.

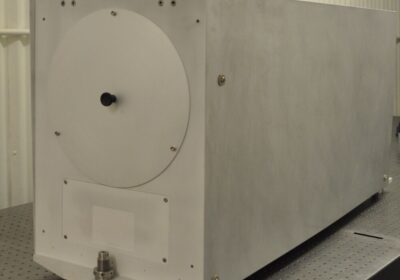

Mantracourt’s T24 range of wireless telemetry for remote monitoring exemplifies advancements in lifting technology. The T24 transmitter provides up to 800 metres of wireless transmission, enabling data to be accessed through tools like the T24 toolkit or SensorSpace platform for cloud-based monitoring.

For operators requiring portability, the T24-HK-S handheld device offers a practical solution, allowing real-time data from multiple transmitters to be monitored on-site. Its ability to deliver overload warnings and alerts through audio or vibration enhances safety, while its durable design ensures reliability in challenging environments. These modular platforms allow operators to tailor their setups to meet specific operational demands, optimising safety and productivity.

The challenges of multi-point lifting operations demand innovative solutions, and the future of the industry lies in embracing these technologies to create safer, more efficient and adaptive workflows. Real-time data systems, supported by wireless connectivity, are helping to achieve this.

To learn more about how Mantracourt’s solutions can enhance your lifting operations, visit www.mantracourt.com.