~ SITA illustrates contaminant and cleanliness inspection capabilities ~

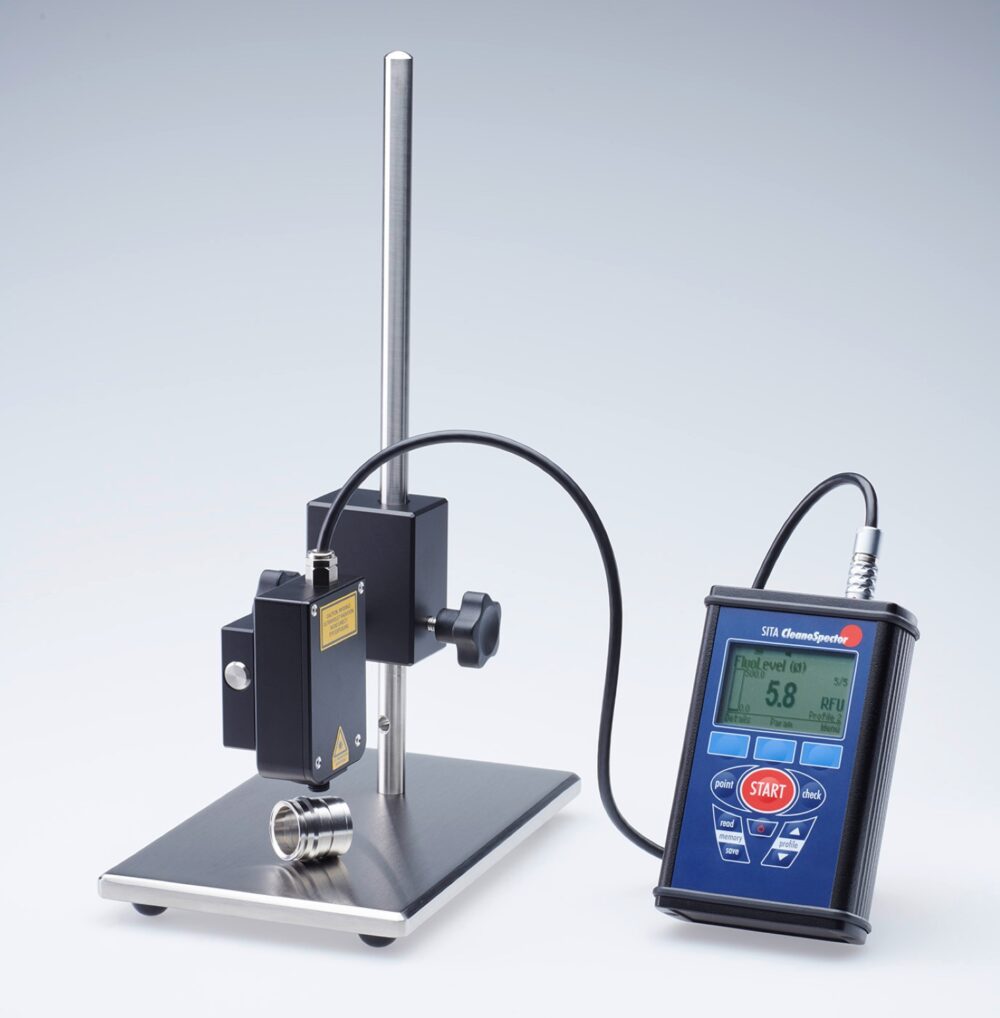

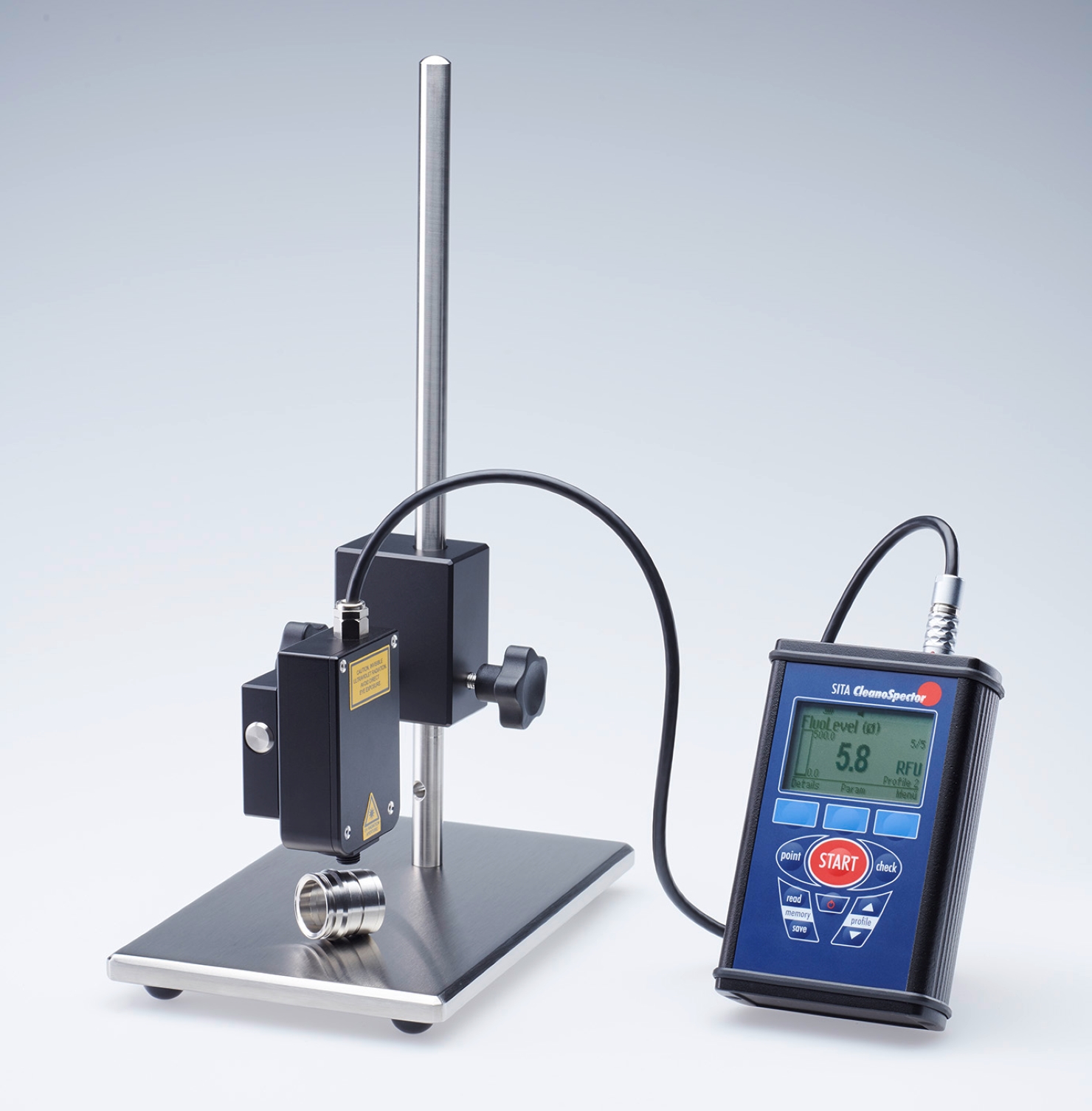

To illustrate how equipment such as the CleanoSpector conducts contaminant and cleanliness inspection within the production process, Dyne Testing, an Intertronics brand, has released a new white paper, Detection of Organic Contamination on Surfaces by Fluorescence Measurement. Based on the expertise provided by André Lohse and Tilo Zachmann from SITA Messtechnik, the article explores the capabilities of fluorescence measurement for surface contamination and cleanliness, and can be read in full on the Dyne Testing website.

The use of fluorescence measurement to determine contamination is a proven non-contact, non-destructive method with high sensitivity and fast response. The white explains how this method can accurately detect and quantify the presence of organic contaminants and allows functional surfaces to be selectively inspected. This is useful ahead of industrial production processes such as adhesive bonding, coating or electron-beam welding.

The article explores the materials and surfaces that can benefit from fluorescence measurement including paper, textiles and plastics, with examples from several industries including bonding, sealing, automotive, electronics, and medical technology.

“Fluorescence measurement devices are an excellent tool to provide contamination analysis throughout in a production and engineering environment, so cleaning processes are evaluated prior to any joining or coating stage,” explained Alison Fox, Brand Manager of Dyne Testing. “Today, instruments such as the CleanoSpector are handheld and can be used to measure for contamination simply and quickly.”

SITA has over 15 years’ experience developing and producing integrated inspection systems for industrial manufacturing, with its range distributed in the UK by Dyne Testing.

The SITA CleanoSpector can be used to measure oil, grease, coolants, release agents, and cleaning fluid on metal surfaces.

Dyne Testing’s surface energy, surface tension, cleanliness, adhesion, coating and substrate thickness, and other inspection products are used in industrial applications to provide quality assurance, process optimisation, and performance enhancement.

To learn more about which equipment can help measure contaminants and cleanliness, and help ensure highest surface quality, download the whitepaper from the Dyne Testing website now, and find out how tools like the SITA CleanoSpector can develop your quality assurance processes.