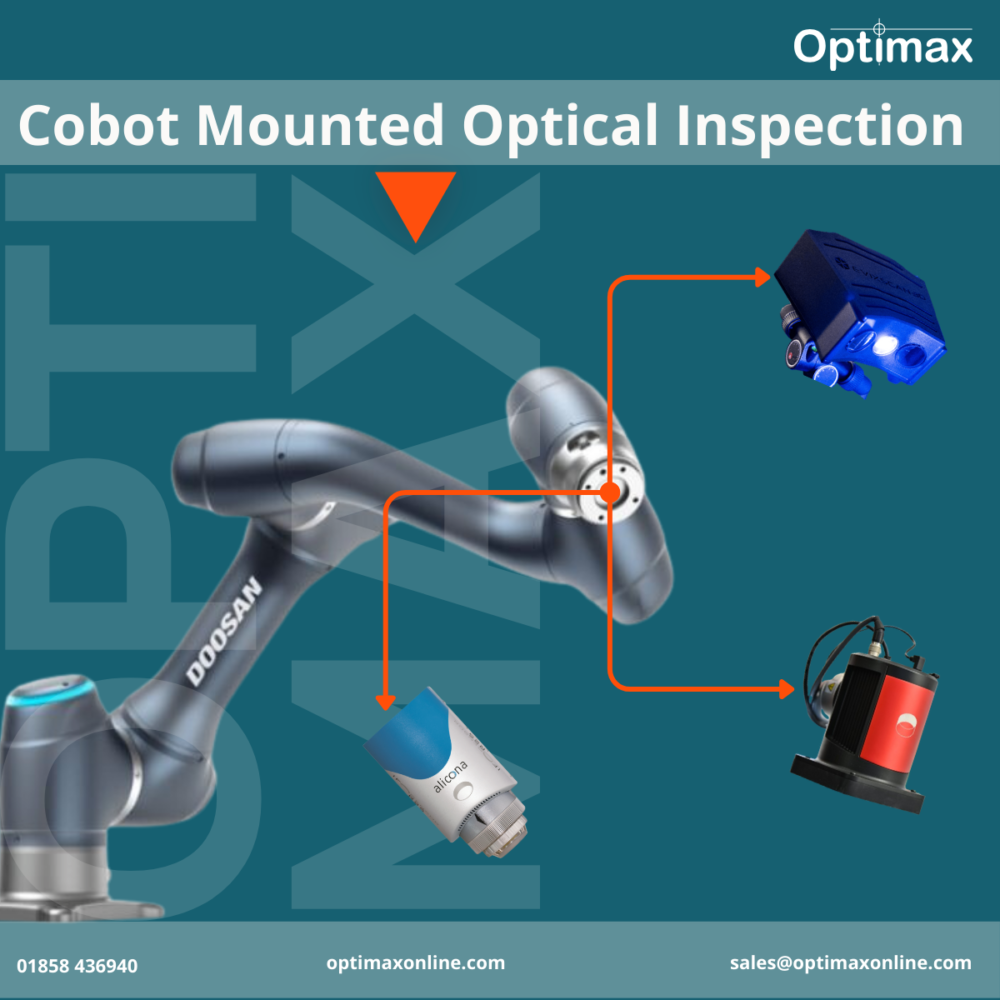

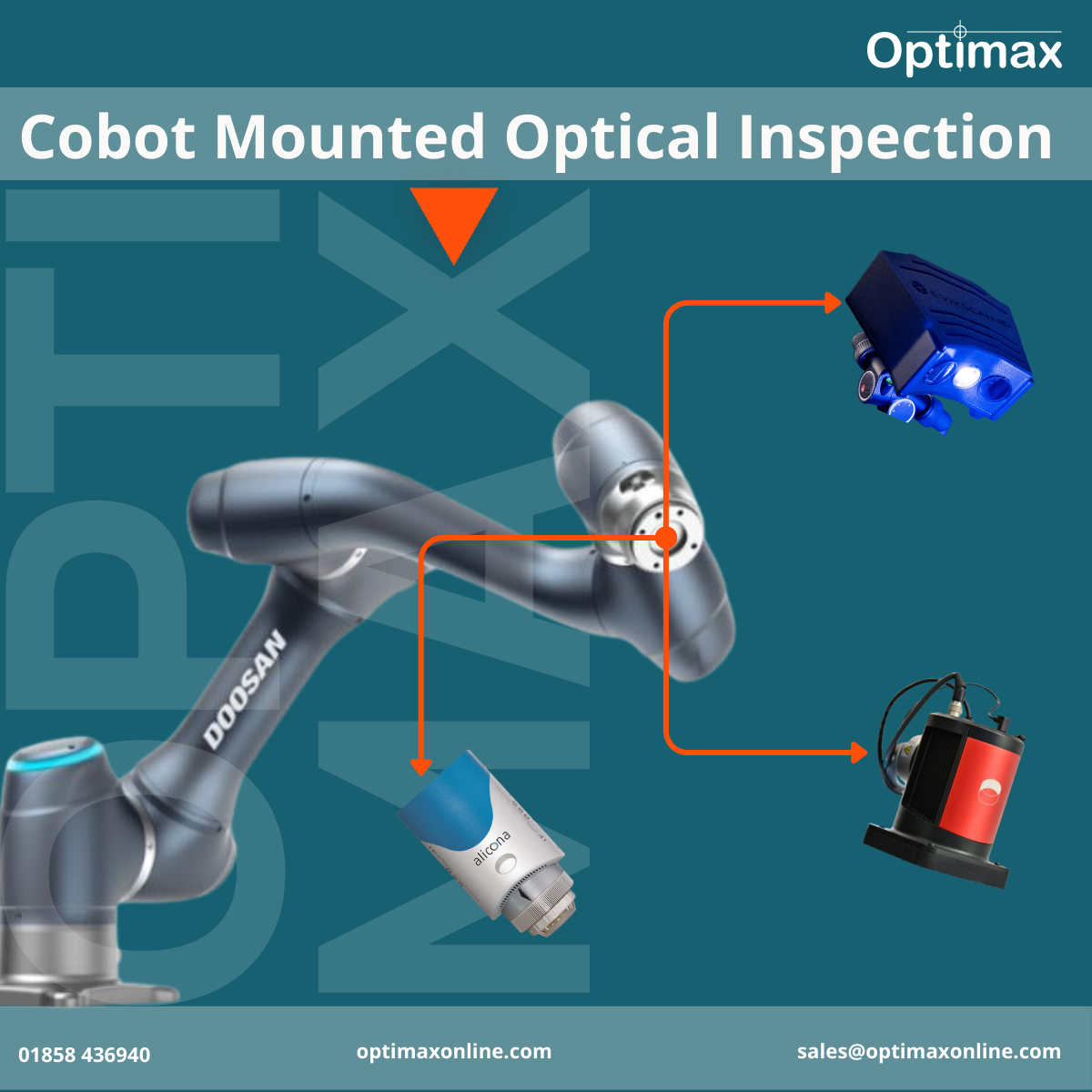

Optimax has announced an exciting new partnership with Doosan Robotics, enabling the seamless integration of Optimax’s advanced measurement and inspection solutions with Doosan’s collaborative robots (cobots).

This partnership introduces a unique capability to the UK market by enabling the integration of a wide range of optical sensors to deliver automated, high-resolution, repeatable, and traceable measurements. Whether the measurement sensor is mounted on the cobot or used to present components to the measurement system, the solutions are designed to perform even in challenging production environments.

Innovative Product Ranges Now Compatible with Doosan Cobots

Optimax’s cutting-edge technologies now integrate seamlessly with Doosan Cobots, including three main product ranges:

Evixscan 3D scanners are known for their precision and versatility, supporting applications such as reverse engineering, quality control, and rapid prototyping. Models like the Optima+ M specialize in scanning medium-sized objects with speed and accuracy, while the Quadro+ scanner offers dual scanning ranges to handle both small and large objects. This dual capability makes it ideal for manufacturing environments requiring flexibility. Using structured light technology, these scanners are tailored for integration into automation systems, such as robotic arms and cobots, aligning perfectly with Industry 4.0 production lines.

Bruker Alicona 3D Metrology Systems have set the benchmark for traceable optical 3D measurement in manufacturing. Among their innovative offerings is the R25 sensor, which integrates effortlessly into production lines and delivers high-resolution, repeatable, and traceable results, especially for measuring micro- or sub-micro-scale surface characteristics. With standardized interfaces like QDAS, the system ensures quick integration and consistent, comparable measurements. Combined with a collaborative 6-axis robot, this system provides unmatched flexibility for quality assurance and the measurement of microstructures on large components.

The Inspekto S70 AI-guided visual inspection system redefines industrial quality control by combining innovative hardware with AI-driven software. It offers human-like flexibility alongside machine-level accuracy, repeatability, and reliability. Whether used as a standalone system or mounted on a cobot for hard-to-access inspections, the S70 delivers outstanding adaptability. Its ability to operate inline or near production makes it an ideal solution for manufacturers seeking efficient and versatile inspection systems.

Comprehensive Customer Support

Optimax works closely with customers to develop tailored, turnkey solutions. Their comprehensive service includes system installation, user training, UKAS-accredited calibration, and ongoing support. Regular calibration ensures that the systems consistently meet stringent industry standards, delivering reliable, high-performing solutions for every application.

The Future of Automated Measurement

The partnership between Optimax and Doosan Robotics brings together the strengths of collaborative robots, advanced 3D scanning, cutting-edge metrology systems, and AI-driven visual inspection technologies. Together, these innovations enable manufacturers across diverse industries to achieve new levels of precision, efficiency, and adaptability in their production processes.

For more information on how this powerful collaboration can transform your production line, contact Optimax today.