~ The testing and management of application specific integrated circuits (ASICs) ~

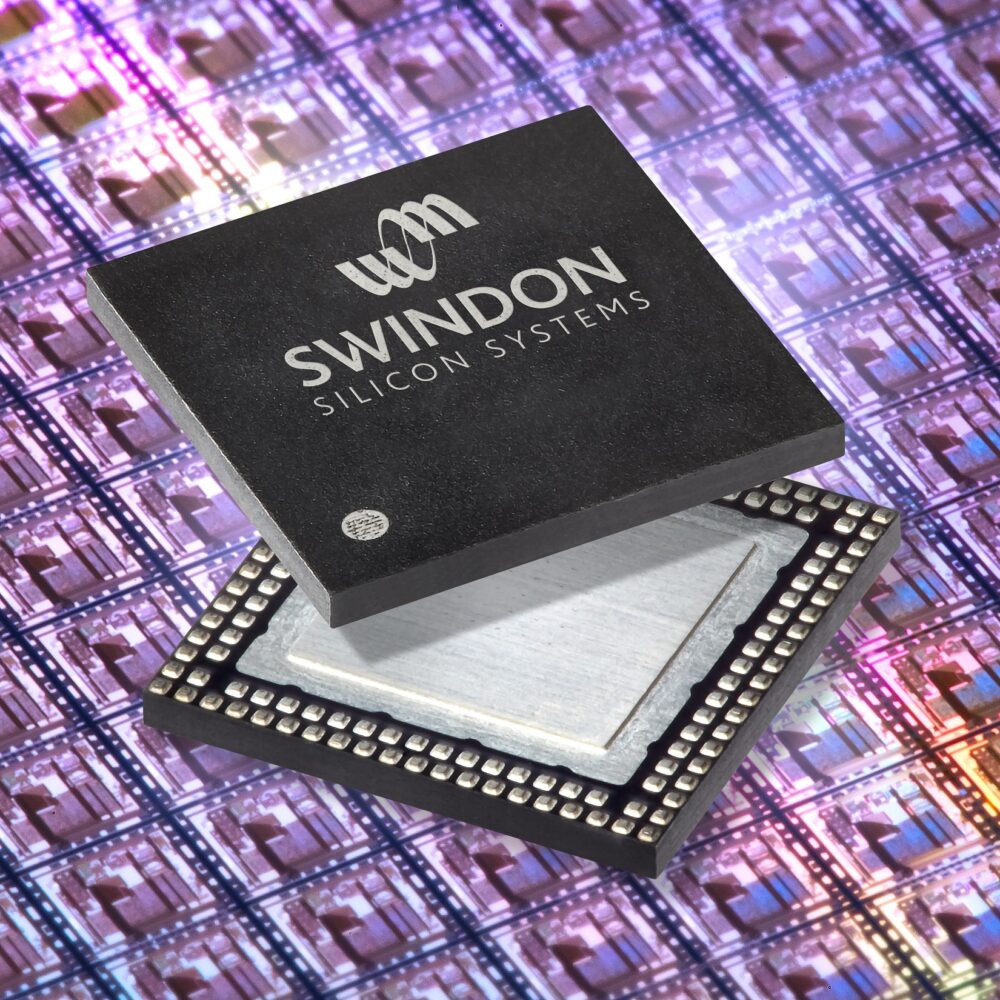

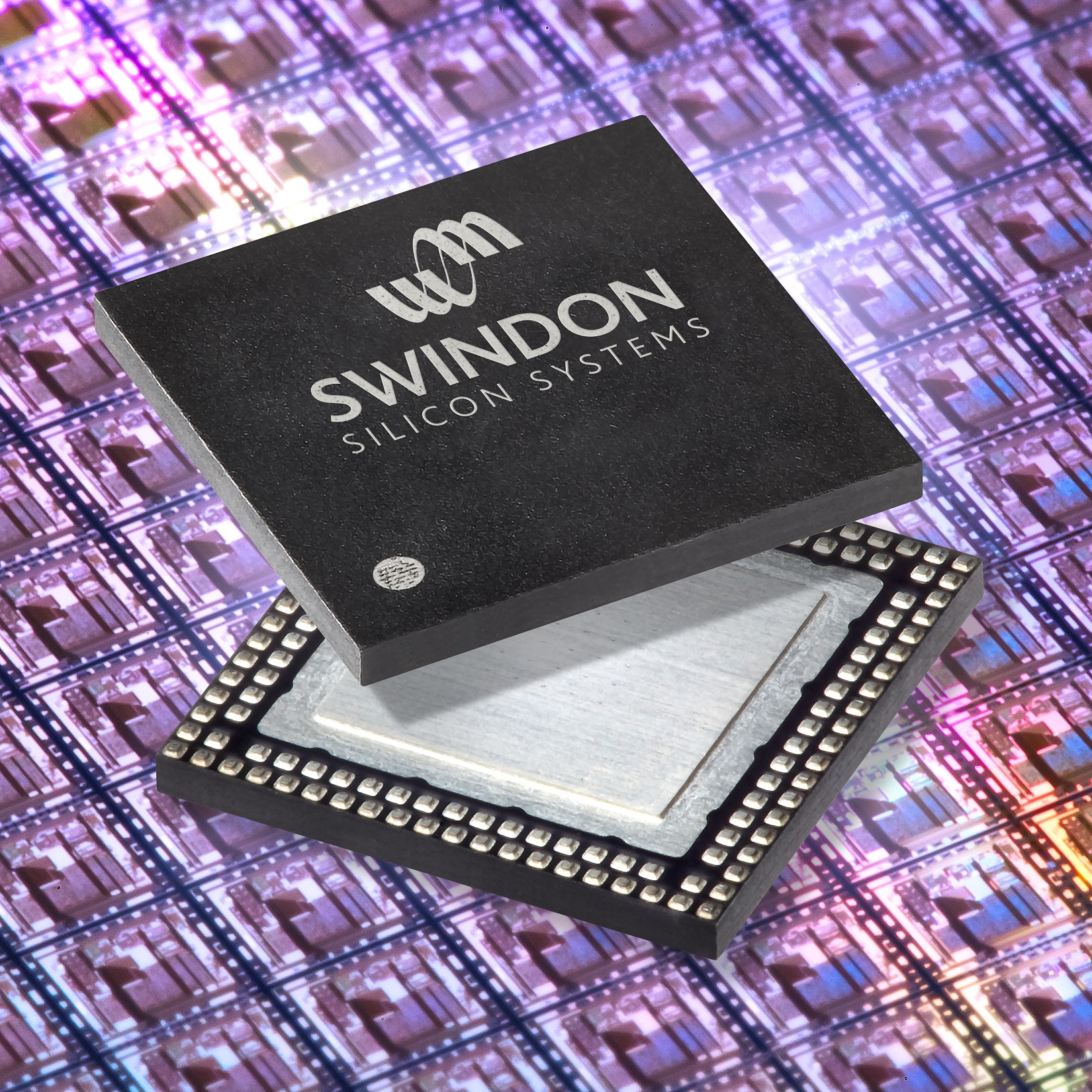

Application specific integrated circuits (ASICs) are the elite choice when it comes to ICs — being designed to meet the unique requirements of an application, they are optimised for a specific function within an electronic system. But with such a bespoke product comes a bespoke production, management and testing system. Here, Ross Turnbull, Director of Business Development and Product Engineering at ASIC design and supply specialist, Swindon Silicon Systems, explains the testing and management mechanisms within ASIC production.

The journey of an ASIC from concept to finished product is complex and involves several stages. The process starts from the customer concept and progresses to the ASIC specification, then onto an early design and simulation, through to layout, prototype verification and production test engineering. At this final stage, we see the results of the customer’s ASIC take shape, which is critical to ensuring the chip performs as intended.

Opting for an ASIC brings many benefits because it ensures bespoke and optimised performance to the customer, but it also delivers a production test procedure specific to their requirements. This test procedure may use wafer probe, automatic test equipment (ATE) or both, and may have different temperature insertions and with calibration over an extended measurement range.

ATE and wafer probe

ATE systems are designed to minimise the amount of test time needed to verify that a particular device works, or to quickly find its faults prior to the part being used in an end product. Expertise in the test of ASICs at this phase, where the identification of parts that do not meet specification, is crucial to the end customer. Delivering parts that are likely to fail in the field or in production will add cost to the customer. The alleviation of this potential is fundamental to the Swindon test department and to the design team.

Wafer probe is another element of the production test, which involves testing the functionality and performance of individual ICs on a wafer before they are separated into individual die and packaged. During the wafer probe process, the entire wafer, containing multiple copies of the ASIC design, is tested using specialised automated test equipment. The wafer is typically placed on a prober, which allows electrical connections to be made between the test equipment and the individual ICs on the wafer to identify defects and ensure only functional, reliable packaged ASICs are delivered to customers.

Swindon uses state-of-the-art ATE to perform high-speed and high-accuracy testing. ATE systems automate the testing process, providing consistent results and detailed data for each chip. These tests ensure the ASIC design team can make any changes to the chip smoothly and quickly and identify and fix any anomalies to ensure a high-yield, on-time delivery of the final ASIC product.

Long-term ASIC management

As with any IC, there are always concerns around obsolescence. The two main components of a custom IC that can go obsolete are the silicon process and the packaging. However, ASICs are designed with non-obsolescence in mind. If a product is designed to last 15 years in production, then the ASIC supplier will choose a suitable silicon process with the required maturity and longevity.

If the silicon process becomes obsolete, the ASIC supplier will normally receive around two years’ notice, providing ample time for a suitable solution to be implemented. The optimum solution depends upon when in the product lifetime obsolescence occurs. If the product is in its last year of life, the customer may prefer to purchase a last time buy (LTB) of fully packaged chips.

For obsolescence that occurs earlier in the product lifespan, an LTB of packaged parts is usually unviable. The next approach is to look at an LTB supply of wafers. This is a much smaller commercial fee, and wafers can be stored in dry nitrogen cupboards for up to 30 years. This effectively acts as a die bank allowing the ASIC supplier to fulfil orders as and when required.

Alternatively, the ASIC supplier could port the design onto a new silicon process, either in the same foundry or a different one. When this option is chosen, the customer may prefer an upgrade in performance, which can be gained from a newer silicon process, or to keep the performance of the IC the same.

The production of ASICs involves meticulous design, rigorous testing and robust obsolescence management to deliver high-performance, reliable chips tailored to specific applications. Swindon prides itself on its comprehensive approach to ASIC development, offering full turnkey (FTK) solutions where all elements of the ASIC design and production process, including testing and ongoing management are done under one roof, making them a trusted partner in delivering innovative ASIC solutions.