~ WEG developed and implemented a customised solution to replace an outdated drive system ~

Implementing fully integrated, energy-efficient solutions in industrial plants can reduce energy consumption by up to 30 percent compared to older systems. Leveraging advances in automation and modern technologies like permanent magnet synchronous motors and variable frequency drives (VFDs), companies can achieve significant improvements in efficiency. In this case, WEG in partnership with its distributor SEBA, located in western France, developed and implemented a customised solution to replace an old drive system to meet the needs of a global player in the metallurgical sector. This project aimed not only to modernise the facility but also to align with the customer’s energy efficiency objectives and adapt to evolving energy standards.

Modernisation for energy savings and sustainability

WEG’s integrated solutions are designed to help energy-intensive sectors like the metallurgical industry transition towards greater sustainability by modernising industrial facilities to deliver significant energy savings.

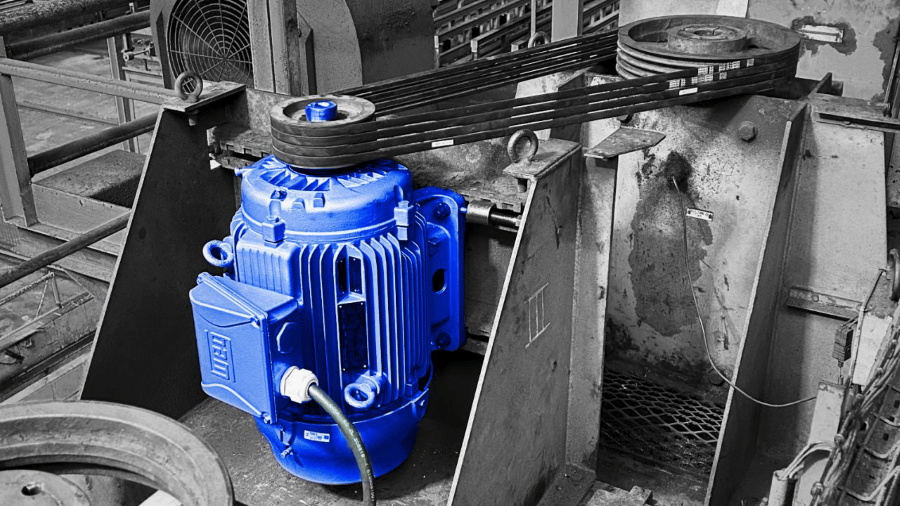

WEG was tasked by SEBA with delivering a turnkey solution to replace a decades-old drive system at the customer’s metallurgical plant. The original installation featured W40 IP23 dual-speed motors, which had been selected for their compact design. However, new energy standards presented technical challenges, particularly in ensuring that the new system would fit within the existing spatial constraints while enhancing performance.

Project scope and customer requirements

The customer’s objectives extended beyond energy savings. The company sought increased operational flexibility and improved process automation. WEG responded by designing a system that integrated VFDs into cabinets, manufactured according to the customer’s precise specifications, including specific equipment references for the cabinet and meeting a tight deadline. WEG had to complete the installation during the end-of-year holiday shutdown.

Technical solution overview

WEG and SEBA’s solution brought a range of critical improvements to the project. By upgrading the system, energy efficiency was significantly enhanced, rising from 83 to over 95 per cent. The use of compact synchronous motors allowed for an interchangeable solution that minimised the need for mechanical modifications to the existing chassis, making the installation smoother. Both factory and field testing were streamlined, ensuring the system operated seamlessly after installation.

The integrated automation solution was housed in a custom-designed cabinet that met the customer’s exact specifications, enhancing process control and efficiency. Additionally, WEG mobilised its teams for a quick turnaround, ensuring that the new system was up and running in time for the customer’s plant restart, with support from WEG France technicians. Throughout the project, close collaboration with SEBA Motorisation ensured that all aspects of the solution were expertly tailored to the customer’s requirements.

Collaboration with SEBA Motorisation

SEBA Motorisation, a long-standing WEG partner, played a crucial role in the project. Based in western France, SEBA is renowned for its expertise in electric motor technology. The company’s team of winders, sales representatives and workshop managers worked alongside WEG to assess the customer’s needs and design an energy-efficient solution tailored to their specifications.

SEBA’s knowledge of both mechanical and electrical systems allowed them to conduct a thorough analysis of the existing installation. Their collaboration with WEG ensured that the final solution would meet the customer’s technical and environmental requirements. SEBA also managed the removal of the old equipment, including replacing outdated cabling with shielded symmetrical multi-conductor cables that comply with WEG standards.

WEG1080 – IMAGE

WEG’s customised motor and drive solution

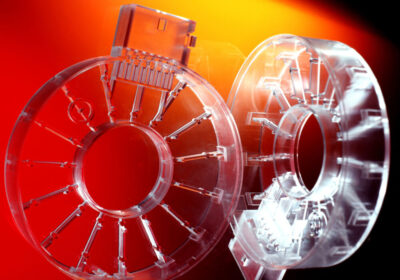

For this project, WEG supplied W22 Magnet motors, renowned for their energy-saving properties and compact design. Four 37 kW, 1500 rpm permanent magnet synchronous motors were installed. These motors were selected based on previous test results, demonstrating their capability to meet the customer’s performance requirements while saving energy.

Additionally, WEG supplied four CFW500 VFDs, which are designed to accurately control motor speed. These drives enable optimal performance by allowing for precise adjustments in motor rotation, which is critical for energy efficiency and operational flexibility.

The project also included the design of a fully customised cabinet by WEG Autrial, a subsidiary of WEG Group based in Valencia, Spain. This cabinet was engineered to meet the customer’s exact specifications for automation and electrical power distribution. The system is flexible and deliver energy savings, while also allowing easy adjustment of parameters through the drive interface. The drives are connected to the main industrial communication bus networks, ensuring seamless integration with the customer’s existing infrastructure.

Commitment to energy efficiency

For decades, WEG has been committed to prioritising energy efficiency in its product development, particularly in synchronous motors and VFDs. WEG produces over 70,000 motors daily, with many achieving the IE5 efficiency classification, the highest energy efficiency standard for electric motors. This level of production enables WEG to quickly meet the demands of large-scale industrial projects.

This project reaffirms WEG’s expertise in delivering energy-efficient, customised solutions to industrial leaders across various sectors, contributing to the customer’s sustainability goals while enhancing operational flexibility and process automation.

To learn more about WEG’s energy saving technology, visit its website.