Harnessing always-on, data driven results

A rise in Industry 4.0 technologies emphasises instantaneous data access for better-informed decision-making. While this is most common in manufacturing, many other ‘point four’ paradigms are embracing the need for always-on, data-driven results. Here, Franz Kamutzki, Senior Sales Account Manager at industrial electron microscopy specialist, Thermo Fisher Scientific, explains the concept of Materials 4.0 and how it addresses the complex material characterisation needs of scientists.

Materials 4.0 represents the convergence of advanced digital technologies with traditional materials science. Inspired by Industry 4.0 principles, this approach leverages big data, high-throughput experimentation and integrated computational tools to reimagine material design and use.

While this sounds promising, bringing Materials 4.0 for microscopy to fruition be difficult and expensive. It often requires labs to have additional IT infrastructure that’s capable of extracting value from the data generated by modern electron microscopes. Additionally, staff may require extensive training on new tools, and scaling these technologies across different departments can be challenging.

Therefore, a microscopy system that’s ready for Materials 4.0 must be able to integrate into existing set ups with ease and streamline data management. But what could this look like?

Scanning electron microscopy and Materials 4.0

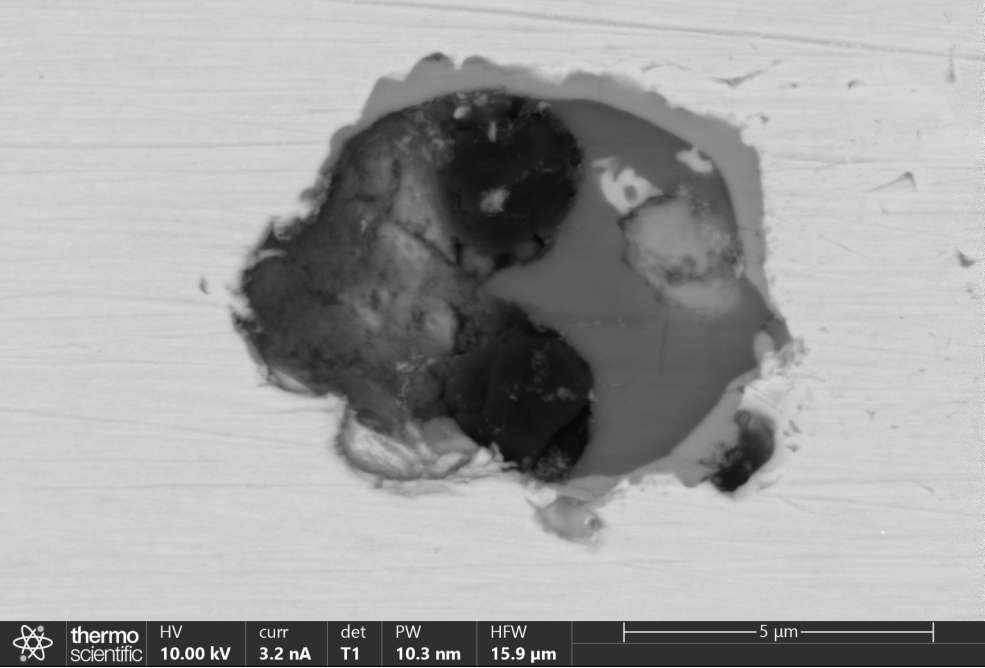

Scanning electron microscopy (SEM) is a vital technology for data-driven material characterisation and analysis. The high-resolution data generated by SEM can be integrated with machine learning algorithms to automate complex microstructural analysis, identify defects and predict material properties. This approach enhances the efficiency of the materials discovery process, allowing for the rapid screening and optimisation of new materials.

Today’s SEMs are a world apart from those used almost 100 years ago. Technologies such as Electron Backscatter Diffraction (EBSD) make it possible to analyse the crystallographic orientation and phase distribution of materials at the microstructural level. By detecting and analysing diffraction patterns from backscattered electrons, EBSD provides detailed maps of grain orientation, phase identification, and strain distribution. This high-resolution, quantitative data is crucial in the context of Materials 4.0.

Consider the study of solid-state batteries. Researchers can monitor the behaviour of the generally crystalline cathode materials using EBSD. This technique allows them to investigate texture, grain size, and boundary distributions, all of which are anticipated to be connected to the electrochemical performance of the cathode material and, consequently, the battery.

A new approach to SEM

Advanced analytics are often thought to require multiple pieces of equipment and software. However, the right SEM can integrate essential features into one platform.

A suitable SEM for Materials 4.0 must offer ultra-high resolution to accurately examine surface features such as grain boundaries and defects. It should also seamlessly integrate with lab automation tools and advanced analytical techniques like Energy Dispersive X-ray Spectroscopy (EDS) and EBSD to simplify data acquisition and reduce reliance on multiple systems. In the example of lithium-ion batteries, combining EDS with SEM could allow researchers to obtain both high-resolution images and chemical composition data simultaneously. This means that, while observing the formation of lithium dendrites in real-time, researchers could also analyse the chemical composition of these dendrites as they form.

An SEM incorporating these technologies directly into its platform allows engineers and materials scientists to acquire comprehensive data — both visual and compositional — in a single setup. It streamlines data acquisition, enhances analysis accuracy and reduces the complexity of managing multiple systems. Consequently, engineers can more efficiently assess material quality and performance, leading to improved reliability and optimised final products.

Thermo Fisher Scientific’s ChemiSEM technology combines traditional SEM imaging with real-time elemental analysis, providing chemical composition directly within the SEM image. This integration enhances productivity and reduces sample analysis complexity.

Now, the company is launching the technology on its Thermo Scientific™ Apreo™ SEM. With a first of its kind integration of SEM, EDS and EBSD analytics, the Apreo ChemiSEM™ removes the barriers of having multiple component and software interfaces. Instead, users can acquire, store, share and analyse material data through a single platform. Where performing EBSD once required a specially trained operator, the Apreo ChemiSEM makes advanced materials analysis possible for all users. Additionally, as analytics are integrated into the SEM, service, support and sales advice all comes from a single point. This means users do not need to juggle multiple service operators and all support can be given from a single Thermo Fisher expert who can help users make the most out of their microscope.

As data-driven decision-making rises across industry, materials analysis faces its own change precipice. While laboratory automation typically required an equipment overhaul and specialised expertise, access to integrable, user-friendly analytics is enabling a sectoral shift. Electron microscopy will remain fundamental in the characterisation and analysis of materials and, when enabled with the latest SEM technology, we’ll see Materials 4.0 truly come to fruition.

To discover how Thermo Fisher’s Apreo ChemiSEM can enable efficiency in your industrial materials process, visit the website.