~ Multi-voltage supply and monitoring device can solve remote challenges ~

Power supplies are often limited in field environments as most of the telemetry industry uses 24V or 12V systems, which can be a challenge when designing battery backup systems. When instrumentation and radio communication devices run on different voltage supplies, having technology that can adapt to the different voltage requirements is convenient and cost-effective. Here, Ian Loudon, International Marketing and Sales Manager at remote monitoring specialist Omniflex, outlines the advantages of dual voltage power supply.

Providing both 24V and 12V in battery standby systems can be expensive and inconvenient. Telemetry equipment is often used in the field to relay information back to control systems, but one of the big challenges is there can often be disparity between radio and instrumentation equipment power supply voltages.

Radio equipment is often powered on 12V DC supply – the most readily available batteries. However, analytical equipment, control relays and others often require 24V DC. Traditionally, companies would use two power supplies to address this issue.

This brings about complexity with more wiring and more maintenance time as this may involve twice the amount of time checking on any signals and twice the cost in cabling.

Traditionally this would require two power supply chargers and batteries for remote monitoring, therefore adding more components to the system. In addition, the draw on the 12V DC system is different to the 24V DC system, which drains the batteries at different rates and makes maintaining them a challenge.

Many teams would carry back up batteries with them, but the most common back up battery is the sealed lead acid because it’s relatively cheap and readily available. In high ambient temperature conditions, however, a charger will even at trickle charge damage the batteries and shorten their lifespan. All sealed lead acid battery manufacturers specify a maximum charging current for the correct life and safe operation of sealed lead acid batteries.

The PTL120C-D takes battery protection to a new level by providing a temperature sensor input – where the sensor is attached to the battery – which allows the charge controller to compensate charging rate according to temperature of the battery extending the battery life significantly. This maximum charging current for a battery is based upon the Ampere-hour capacity of the battery.

Many conventional switch mode power supplies do not control their maximum delivered current and can cause batteries to be charged from flat with current levels that exceed the manufacturer’s recommendation.

In addition, during prolonged power outages, back-up batteries will eventually discharge. If the load remains connected, the batteries can enter their “deep” discharge phase, which can cause irreparable damage to the batteries, and reduce their capacity and life expectancy.

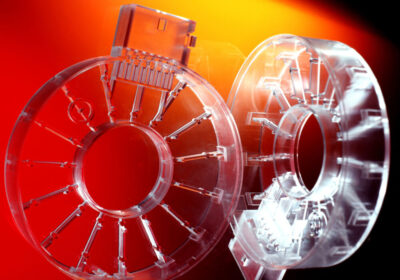

To simplify the challenges of remote monitoring Omniflex has developed a single product solution by developing a power supply with the PTL120C-D dual voltage charger – with both 12V and 24V DC output. It provides true split rail battery charging for balanced charging to both batteries even when 12V loads are tapped from the battery set.

This protects the batteries from any deep discharge events, containing mains output that is connected as an alarm to indicate loss of primary power – notifying a supervisory system. The battery level is monitored through the charger and the load can be put to prevent damage, alerting a specialist to fix the problem.

With a simplified design through a compact single unit solution, this makes maintenance easier and flexible by avoiding the necessity for certified wiremen to change power supply through a mains safe IEC connector.

To find out how you can simplify maintenance and save costs by protecting your battery investment with the PTL120C-D dual voltage charger, get in touch with Omniflex today.