~ Radar technologies for quarry level management give competitive edge ~

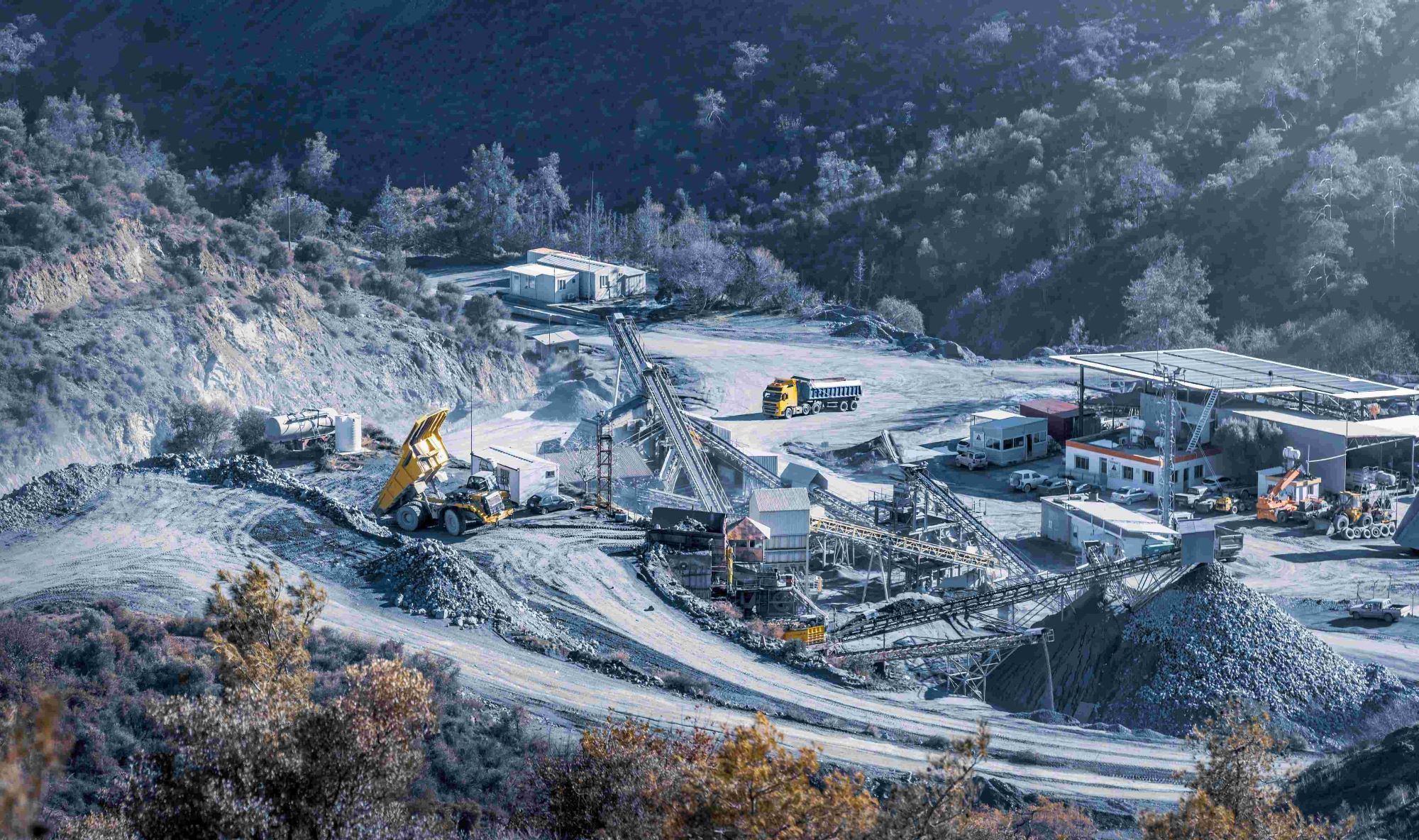

There’s an “imperative for the Top 40 mining companies to focus on productivity,” reports PwC and accurate level measurement is particularly essential in efficient operations. However, the harsh environment of quarries — filled with dust, moisture and noise — poses significant challenges to traditional measurement technologies. Here, David Strain from Technidrive, an expert in integrated automation systems, explains how, despite these obstacles, recent advancements in radar technology have opened new doors for more reliable and accurate level measurement. The results? Enhanced productivity and operational efficiency in quarries.

PwC’s Mine 2024 report cites several reasons why quarries must be more productive “in today’s increasingly complex mining landscape.” Those factors include “expanding commitments to sustainability, rising production costs, declining ore grades, more dispersed reserves and a shortage of technology-savvy talent.”

As a solution, PwC recommends the largest mining companies turn to technological advancements. Specifically, advanced sorting and measurement technologies that can enhance the efficiency of material handling and processing.

Among these technologies, level measurement plays a critical role in efficient quarry operations. Level measurement is essential for managing the flow of materials through various stages of production, from extraction to processing. What’s more, these processes must be accurate to ensure that crushers, screens and conveyors are fed with the right amount of material at the right time to prevent the overloading or underfeeding of equipment. This not only optimises production, but also extends the lifespan of machinery by reducing unnecessary strain.

What is level measurement?

In quarries, level measurement is used to monitor the volume of materials such as aggregates, sand and gravel in storage bins, hoppers and silos. Knowing the exact levels in these containers is vital for inventory management, ensuring there is always enough material available to meet production demands without causing delays. Additionally, maintaining optimal levels helps prevent blockages and spillage, which can lead to costly downtime and safety hazards.

Another crucial aspect of level measurement is its role in process control. By continuously monitoring material levels, quarries can automate their processes to adjust the flow of materials in real time. For instance, if the level in a hopper drops below a certain point, the system can automatically increase the feed rate to maintain consistent output. This level of automation reduces the need for manual intervention, improves efficiency and minimises the risk of human error.

Traditional methods

Quarry operations present a unique set of challenges when it comes to level measurement. Traditional methods, such as ultrasonic sensors, have long been the industry standard, relying on sound echoes to determine the level of materials. However, these sensors are highly susceptible to interference from dust, noise and moisture, all of which are abundant in a quarry environment.

Moreover, objects protruding from structures can cause false readings, leading to inaccurate measurements that disrupt the entire operation. These limitations not only hinder efficiency but also increase the need for manual intervention, further complicating the process.

To address these challenges, the industry has explored various solutions, but many have proven inadequate or too costly to implement on a large scale. Ultrasonic technology, despite its limitations, remained dominant due to its affordability. However, as quarries strive for greater efficiency and automation, the demand for more reliable and robust solutions has grown.

This has led to the exploration of radar technology, which offers a more accurate alternative to ultrasonic sensors. Yet, for many years, radar was considered too expensive and complex to be widely adopted in the quarrying industry.

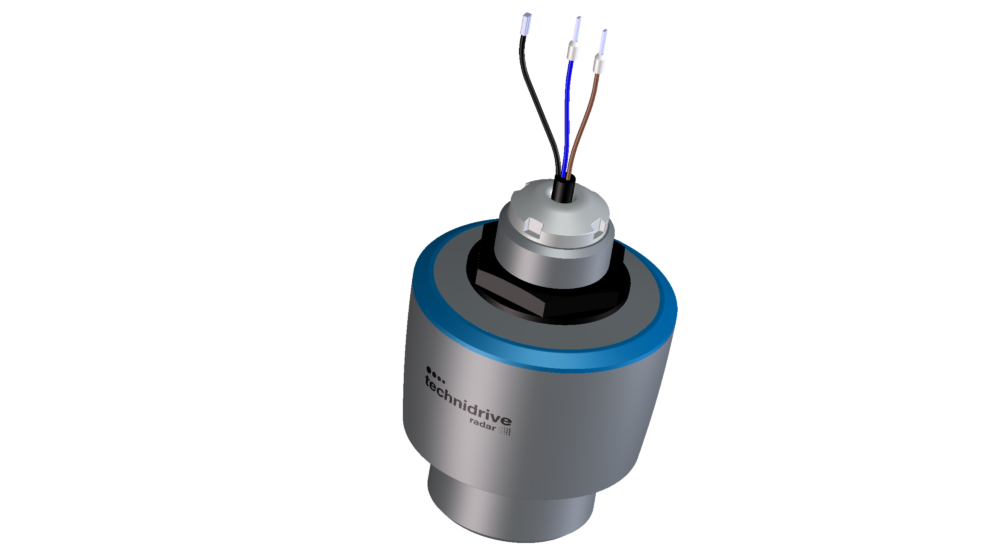

TCH142

Radar technology

Technidrive recognises the potential of radar technology to revolutionise quarry level measurement. With the introduction of 80 GHz radar sensors, it is now possible to provide clients with a solution that overcomes the limitations of ultrasonic sensors. Unlike sound waves, radar waves are unaffected by dust, moisture and noise, making them ideal for the challenging quarry environment. These sensors offer unparalleled accuracy and reliability, allowing for more precise level measurement.

A holistic approach is needed when integrating radar technology with other advanced systems. Radar sensors can be combined with Smart PID control, an advanced version of traditional Proportional-Integral-Derivative (PID) control systems that are widely used in automation to maintain a desired output by adjusting inputs based on feedback.

The sensors can also be combined with WEG’s Pump Genius programmable software that, put simply, enables standard variable speed dives (VSDs) to become dedicated for pumping systems. With easy-to-use programming, the software ensures accurate control to minimise downtime and maximise energy savings. Automatic adjustments can be made in real time based on the data received from the sensors.

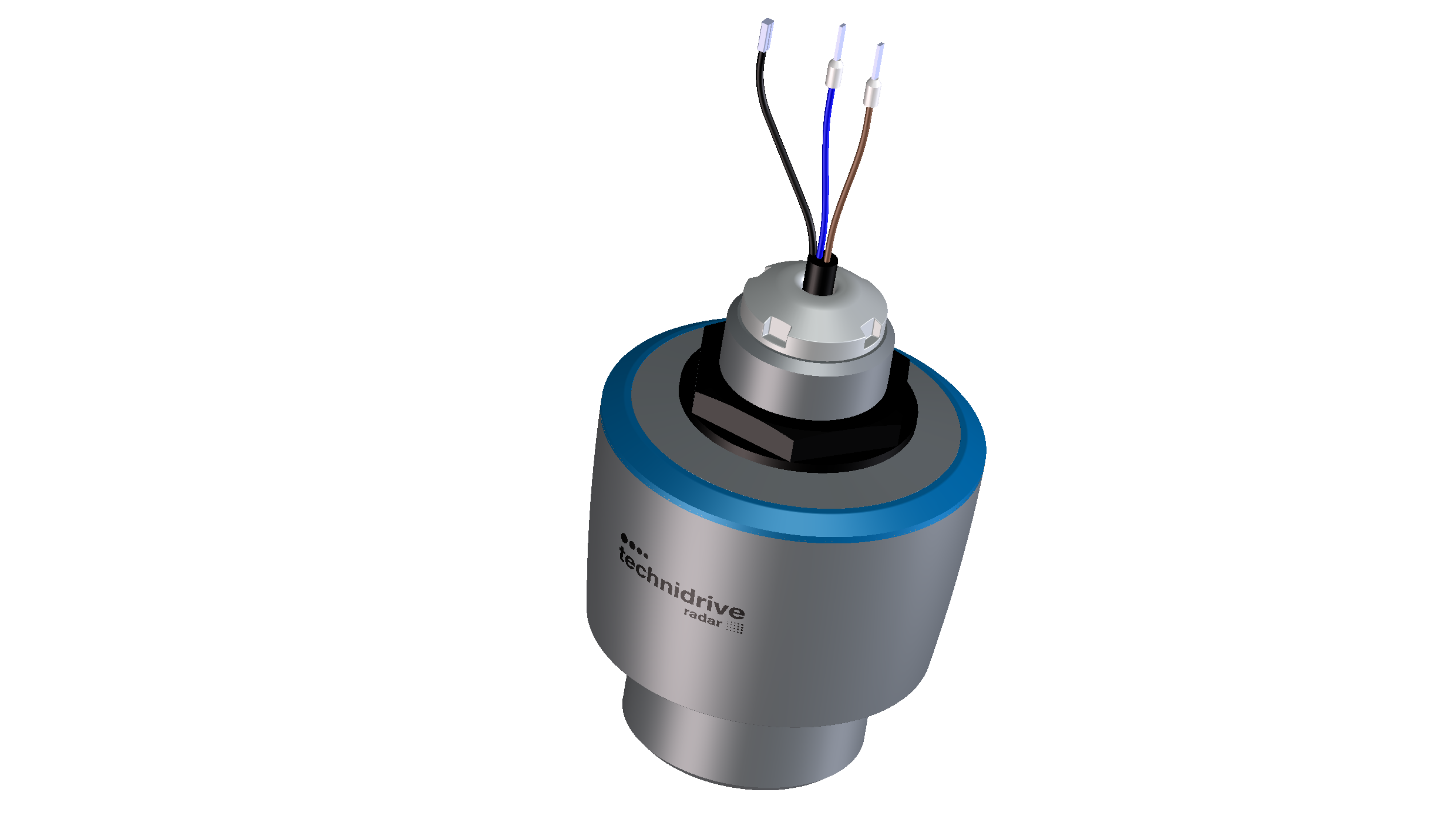

TCH143

For example, in a wash plant, if the demand on a screen increases, the pump will automatically adjust the flow to meet that demand without the need for manual intervention. This level of automation enhances efficiency and reduces downtime and maintenance costs.

In addition to improving on-site operations, Technidrive has implemented wireless communication systems that allow for remote monitoring of material levels across the quarry. This data is transmitted via a networking or communication system to a central dashboard, providing managers and stakeholders with real-time insights into their operations. By leveraging this data, quarries can optimise their processes, ensuring that all equipment operates at its optimum level.

Advancements in radar technology offer a promising solution to the obstacles of the hazardous quarrying industry — in line with the recommendation in PwC’s Mine 2024 report that “technological advancements and increased investments are major drivers of progress.” As the industry continues to evolve, embracing these cutting-edge technologies will be crucial for improving efficiency and maintaining a competitive edge.

For more information on how advanced automation and VEGA radar technologies support quarrying applications, visit Technidrive’s website.