Global composites manufacturer Exel Composites has secured an extension to a design patent in Finland for its antenna radomes. The move broadens the company’s intellectual property to include a new, discontinuous technique that incorporates a range of functional zones in the radomes. This design is optimized for all frequency bands used in mmWave telecommunications. As well as enhancing the performance of existing 5G technology, the layered manufacturing technique also provides superior structural possibilities for other industries such as transportation, construction, and more.

Exel-Composites-small-cell-mmWave-composites

The previous iteration of Exel Composites’ patent covered radomes that feature signal windows, which allow uninterrupted transmission. The technological leader in pultruded glass fiber radomes recently developed and patented its revolutionary technology that adds discrete material elements to form ‘functional zones’ inside the material.

These functional zones can be reinforced structural parts, insulating sections, and radio frequency (RF) transparent areas among others. Exel achieves these zones by sandwiching different materials such as RF transparent foam in a fiberglass skin. This method optimizes the skin’s thickness and distance from the foam core to minimize signal loss and reflection.

Previously, when the profiles were cut from the continuous output, their edges were exposed to humidity. This technique provides additional reinforcement applied to the areas to be cut. The foam inside is protected from moisture as well as impact damage.

These discrete additions further optimize the properties that composite materials are known for. Glass fiber profiles are very lightweight and have great longitudinal stiffness. Bonding transverse directional stiffeners on top of the profile would make the end product heavier but this new ability to add additional internal strengthening material negates that problem.

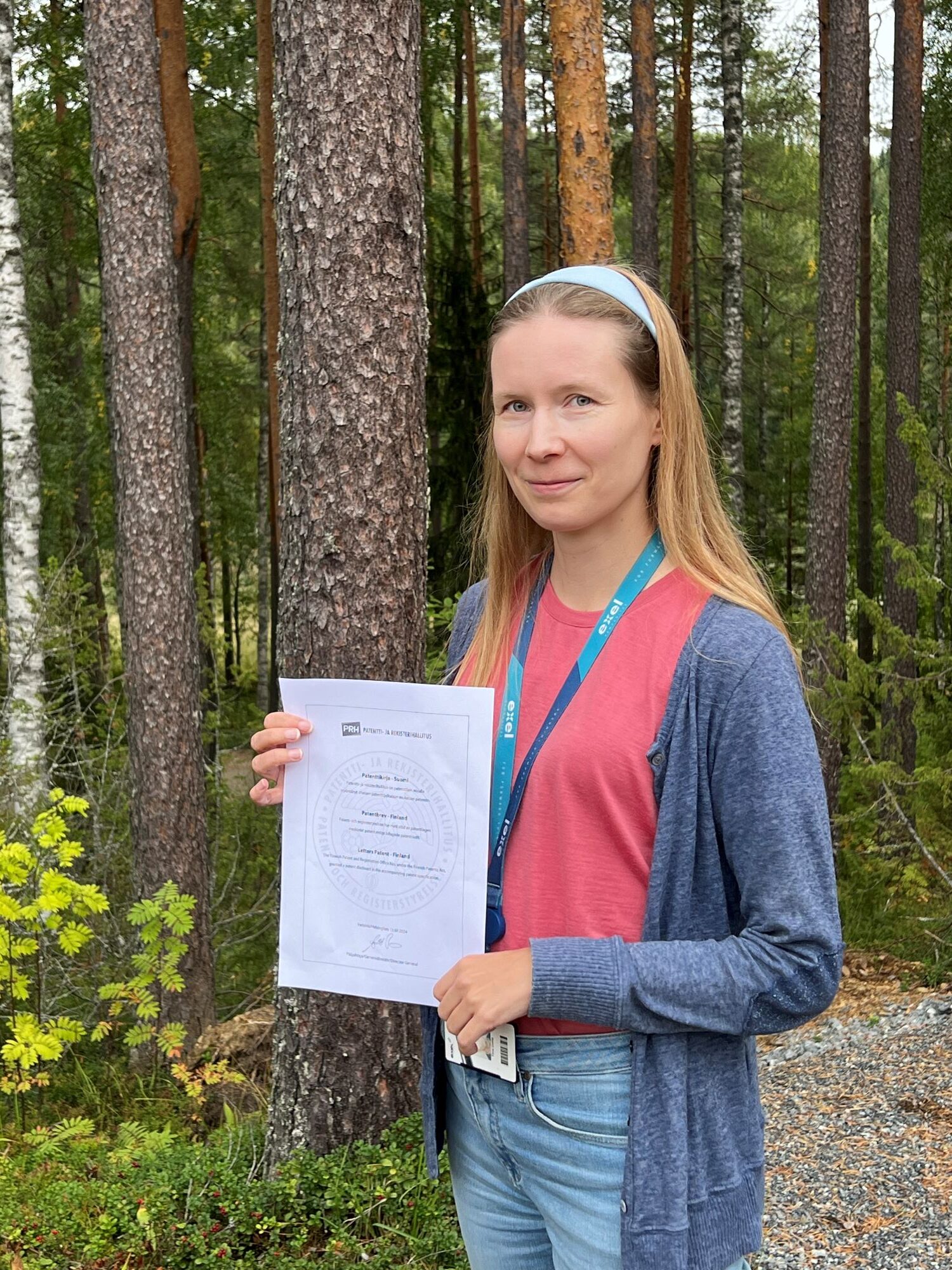

“Pultrusion, a continuous manufacturing technique, is ideal for large and/or wide profiles. It has always been flexible, capable of producing different 2D shapes,” explained Tiina Uotila, technical sales manager at Exel Composites and the inventor of this type of pultrusion for radomes. “Now, this development shows progress in pultrusion’s use for multi-layered designs.

“The signal windows can be tailored to any frequency and, with our new technique, we can balance transmission demands with structural reinforcement and thermal and electrical insulation,” concluded Uotila. “This capacity to add discrete elements to composite profiles, of different shapes, textures, and sizes, opens up countless new manufacturing options. I encourage our customers to approach us to test ideas in their own industries.”

Exel Composites will register this patent worldwide in active markets. Beyond telecommunications, the company intends to market this sandwich technology in other industries. This complex profile type can give RF transparency to lightweight, rigid bus panels and insulating building materials in new developments, in addition to applications that have not been discovered yet.

Tiina Uotila

To learn more about Exel Composites’ innovative offerings for the telecommunications sector, go to https://exelcomposites.com/composite-solutions/composites-for-telecommunications/