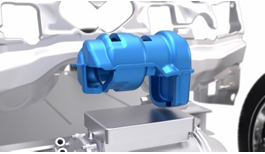

To address the acoustic challenges of electric vehicles, Hutchinson has developed an NVH (noise vibration, harshness) encapsulation solution with acoustic and thermal properties to reduce the noise of cooling compressors and e-motors.

Environmentally friendly and lightweight, it has been designed to equip several thousands of electric and hybrid vehicles around the world for major international OEMs.

With the rise of electric vehicles (EVs) like BEVs and PHEVs, new challenges related to acoustics and comfort are emerging. Cabin noises can arise from multiple sources and occur while the vehicle is on the move, stopped, or parked, especially during the fast charge. Noises from powertrains and electric compressors were previously masked by combustion engines, but they are becoming increasingly obvious.

This leads OEMs and equipment suppliers to search for new ways to address noise pollution challenges while respecting new insulation regulations.

Expert in sealing and insulation technologies, specialized in the production of high-quality hush panels and acoustic solutions, Hutchinson has designed an innovative multi-layer cover with advanced acoustic properties for electric & hybrid vehicles. This encapsulation solution offers an excellent combination of vibration attenuation and absorption, especially at high frequencies (>1000 Hz), attenuating the noises of e-compressors and e-motors.

Incredibly lightweight and 100% recyclable, this solution demonstrates Hutchinson’s commitment to sustainability objectives.

High-end material expertise enables Hutchinson to improve the e-compressor performance and the active cooling systems for e-motors with optimal thermal insulation properties. Combined with NVH brackets, it offers the best damping solution for e-compressors and e-motors.

Hutchinson’s acoustic cover has been validated and selected by major international OEMs to equip over 600,000 vehicles a year in Europe and China.

To ensure compliance with customer specifications and design the optimal cover, our engineering teams carried out a series of tests and validations with the support of the Group’s Research & Innovation Center: acoustic tests such as sound absorption, transmission, insertion loss measurement, corrosion, resistance to automotive fluids and vibration. These tests have been performed on the cover, lid, and its components, as well as numerical modeling for thermal efficiency.

With their deep technical knowledge, Hutchinson adapts the design to the space available in the vehicle and to the required technical constraints. “The challenge was to find the best balance between comfort, noise reduction, mass minimization, industrial feasibility, and durability to ensure that the solutions meet the highest standards of performance and reliability. Through this system, we provide an effective response to environmental challenges and customer expectations,” explained Luis Lafuente, technical leader in Vittoria, Spain.

Hutchinson is leading the way in enhanced acoustic comfort and contributing to overcoming the challenges of acoustic insulation for BEV’s, HEV’s drivers and passengers, today and in the future. This innovative encapsulation solution received the President’s Prize at the Hutchinson Awards in the category electrification in June 2024.