Designed specifically to meet the needs of the liquid

hydrocarbon and gas measurement markets worldwide

Measurements conforming to AGA, ISO, API standards

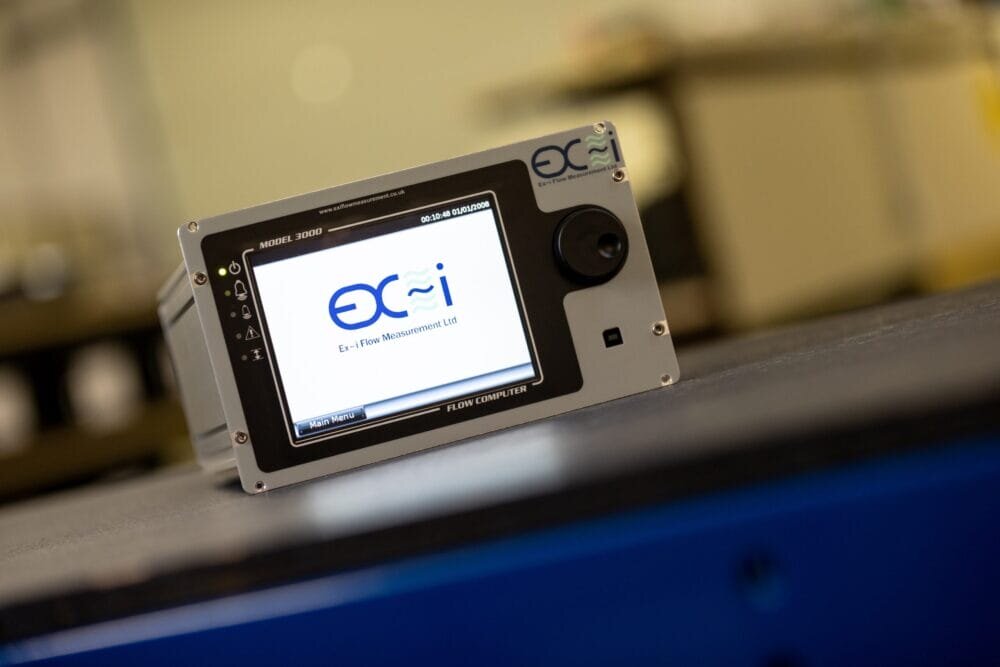

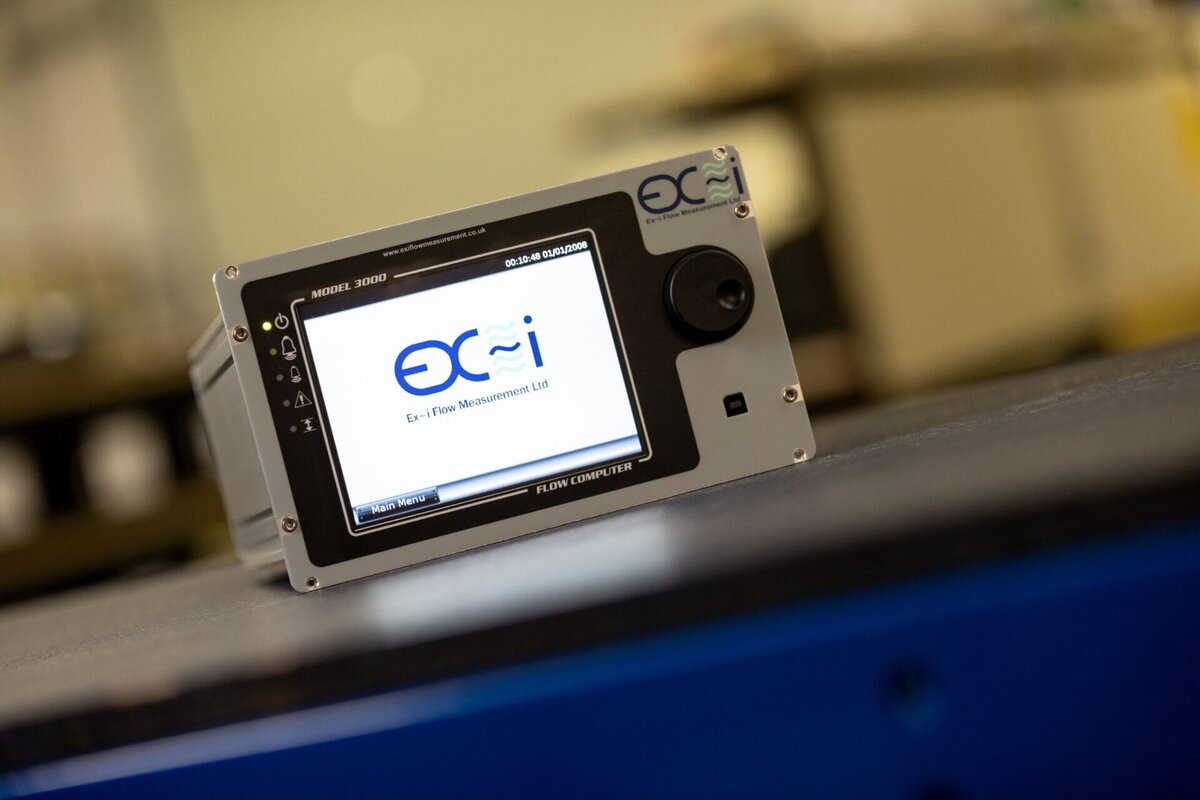

The SFC3000 flow computer from Sussex based Ex-i Flow Measurement Ltd,. is a highly versatile liquid hydrocarbon and gas flow measuring device capable of operating in a stand-alone single stream flow measurement system or as part of a highly complex multi-stream system.

The SFC3000 is far more than just a dedicated flow computer. It can operate on a number of levels from a supervisory machine to a standalone flow computer or as a system component. With its touch screen VGA display and extensive processing capabilities, combined with simple to use controls and unique operating software, it can function as a complete station supervisor integrated into a flow computer housing.

Designed specifically to meet the needs of the worldwide liquid hydrocarbon and gas measurement markets, the SFC3000 is intended to positively contribute to both management and conservation of the world’s dwindling energy resources by providing both versatile and accurate measurement and incorporating state of the art designs and components.

The SFC3000 flow computer should be considered the “brains” of a flow measurement system and requires a number of peripheral components to take measurements. In its simplest form, a flow measurement system will consist of:

- An SFC3000 flow computer with 1 I/O option board

- A flow meter (turbine, ultrasonic, differential pressure or Coriolis)

- A pressure sensor (HART or 4-20mA)

- A temperature sensor (Hart, 4-20mA or PT100 Platinum Resistance Thermometer).

Note: pressure and temperature sensors are not needed with a Coriolis flow meter, and additional pressure sensors are required for a differential pressure meter.

Turbine, ultrasonic and Coriolis flow meters can be connected using a pulse input, either as a single or dual pulse train. Alternatively, ultrasonic and Coriolis flow meters can be connected via the RS232/485 serial port available on each of the IO option boards.

Additional functionality can be added to a basic system including optional I/O boards. With the addition of a communication board data can be obtained from a gas chromatograph or other sources via the serial or ethernet ports. Flow measurement data can also be passed to other systems, such printers or DCS, via the communication board ports. Logged data can be stored internally or in an optional SD card. A density measurement cell can be connected to a pulse or 4-20mA input.

The attached photograph shows the EX-i SFC3000 flow computer

SFC3000 flow computer key features:

- Measurement conforming to AGA, ISO, API standards of: dry and wet natural gas, hydrocarbon liquids, other gases e.g. nitrogen, other liquids e.g. water.

- NMi Certificates to: WELMEC 7.2 and 8.8, OIML R117, MID 2014/32/EU

- Standard Features: standalone flow computing function, flow computing combined with supervisory function, up to 2 G-byte additional memory for Alarm, Audit and Data Logging, optional SD card required.

- Meter types: pulse generating flow meters, most common ultrasonic flow meters, dp transmitters with orifice or venturi measurements

- Configurable Display: system diagrams, Trending and graphical displays, Language options, Interfaces to most types of metering equipment and all popular GC’s, Easy Installation and interfacing

- Supervisory Features, Alarm/Event/Data Logging and Recording, Printer Report Generation, System Diagram Display, Network Communication, Station Controller Functions, Valve Control and Remote Operation.

- Maintenance Functions: stream summation, pid/sampler functions, flow computer specification.

The SFC3000 is packaged in an industry Standard Half Width 3U High 19” rack construction suitable for panel or chassis mount. It can accommodate up to 6 user plug-in cards and up to five measurement streams in the same chassis. Operating temperature ranges; PRT Inputs, -10°C to 55°C (15°F to 130°F), Hart® and 4-20mA Inputs -25°C to 55°C (-15°F to 130°F). Operating humidity to 90% non-condensing and meets environmental classes M2/E2.

The future of gas and liquid measurement and flow control innovates through a continuous process of evolution. As leading flow computer manufacturers, Ex-i Flow Measurement specialises in researching, developing and manufacturing products for the gas and liquid measurement industry, with a focus on continuous project development and enhancement. EX-i offer customers market leading performance, quality, reliability, cost and response.

For more information call +44 (0)1243 554920, email [email protected] or visit https://exiflowmeasurement.com/