~ Why measuring power quality on the grid’s edge is critical ~

According to electric vehicle (EV) charging specialist Zapmap, at the end of November 2023 there were around 950,000 fully electric cars on UK roads, with 15.6% of all new car registrations being electric. As with other electrical devices, more EVs creates more strain on our national grid. Here, John Mitchell, global sales & marketing director at CP Automation, explains why active monitoring will be essential if we are to understand the effects of EVs on power quality — and this includes going back to the grid’s edge.

The electricity market has seen an exponential change in recent years. Technological advancements, evolving customer preferences and changes in legislation are all causing a surge in the adoption of solar power, battery storage systems, microgrids, EVs and other devices. The number of these distributed energy resources (DERs) is growing — and they all have different switching frequencies.

As our nation’s power supply moves away from centralised generation at large-scale facilities in favour of smaller, distributed, generation units, the effects of a busy network are felt most by end users near the grid’s edge.

The problem with power

According to the energy consultancy Wood Mackenzie, the grid’s edge “covers all the distributed hardware, software and business innovations that exist in proximity to the end user, rather than at the centre of a traditional generation network.”

The country’s shift towards decentralised energy will only put further pressure on the grid. Aside from the growing number of EVs and charge points, the rise of other electric energy sources like heating and wind turbines are negatively impacting power security. Harmonics are also a growing issue if they aren’t identified fast.

Over the years, industrial facilities have tried to improve power quality using new drives and other technologies, but these initiatives have brought fresh challenges. For example, because motors are inductive devices, they generally have a poor power factor (PF), so operators would traditionally fit a capacitor to bring the inductive part of the load back into unity, with a PF of 1.0. This meant the motor would consume 100% of the power it draws.

Today, variable speed drives (VSDs) are a common sight in many industrial facilities; they sit in front of motors and provide good power factor correction (PFC). However, VSDs can also create harmonics that can impact transformers and other equipment. Therefore, while capacitors are no longer a necessity, harmonic filters may be.

The value of metering

While many industrial businesses are investing in mitigating harmonics and other issues, measurement may not always first come to mind. Understandably, the focus is on resolving issues before they snowball. Nevertheless, failing to monitor the supply regularly could leave operators in the dark. Even the most experienced operators can’t know what they don’t know.

A simple way to measure power quality is to compare voltage readings between accurate voltmeters, using an electromechanical movement meter and a more high-quality digital meter. However, this will only provide a very limited picture, mainly of harmonic content. Instead, using a more advanced metering system that covers various parameters is recommended.

Making the right choice

There are three types of meters. The first is a very basic product that only tracks power and energy consumption. Next is a more advanced version that will measure a wide range of parameters, including harmonics and transients. Finally, high-end power analysers, such as Janitza’s UMG 96-PQ-L, go the extra mile by covering a wide range of scenarios, including supraharmonics.

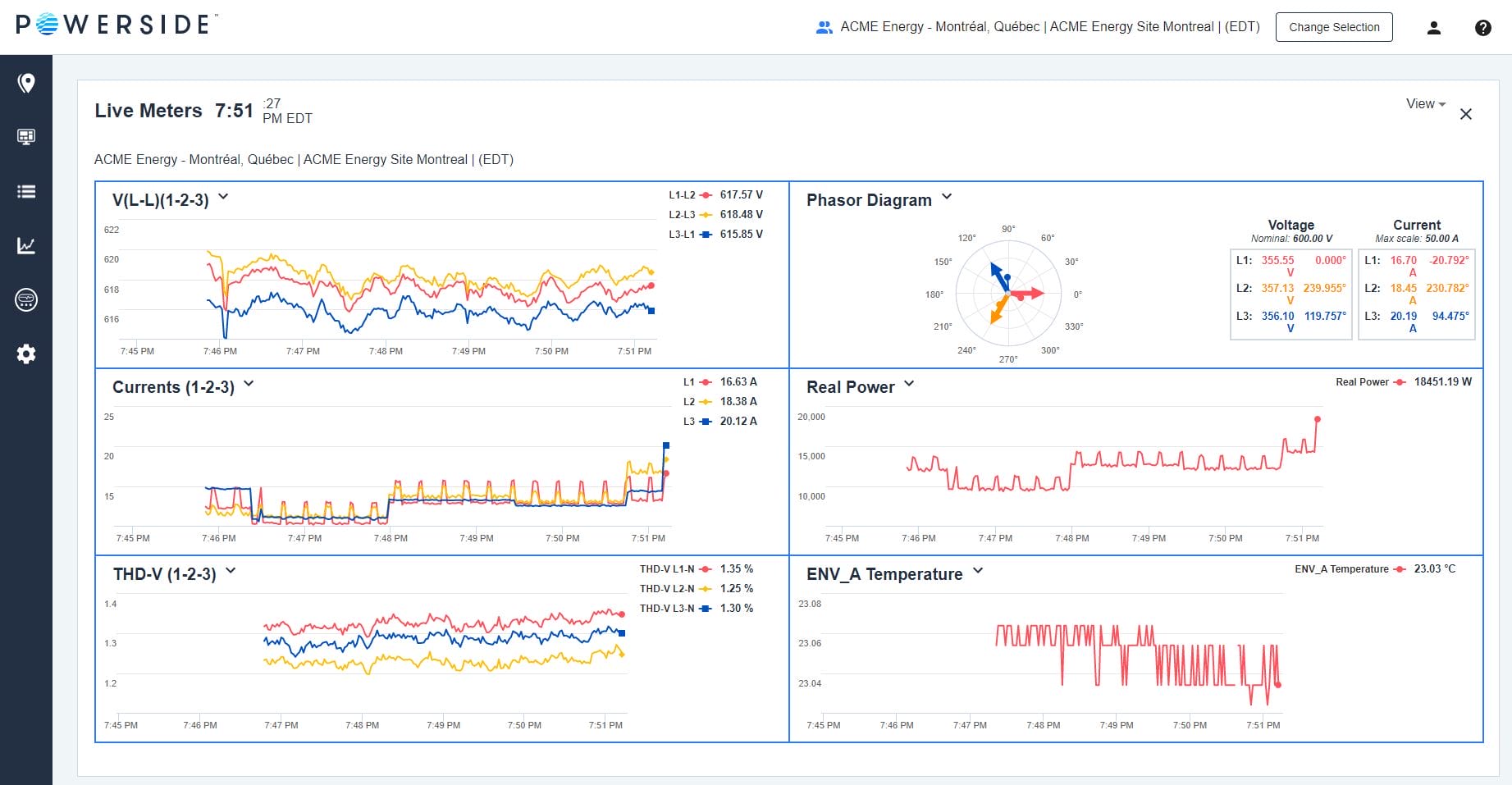

Remember, a basic metering system will only offer very limited insights. Being able to capture data on far-reaching parameters like voltage spikes, voltage drops and harmonics is invaluable. To this end, operators can go further by integrating additional analysis software and tools. For example, Powerside’s QubeScan, a cloud-based platform, identifies undetected issues like harmonics, voltage fluctuations and flickers. This data allows operators to anticipate power failures at the grid edge and respond proactively to problems.

The number of EVs and other DERs may be on the rise, yet the proliferation of these alternative energy sources should not damage site uptime. By investing in technologies that measure power quality, and by selecting a metering system that covers a wide range of parameters, operators can be proactive and prevent downtime.

To find out more about CP Automation’s range of power quality metering technology, visit its website.