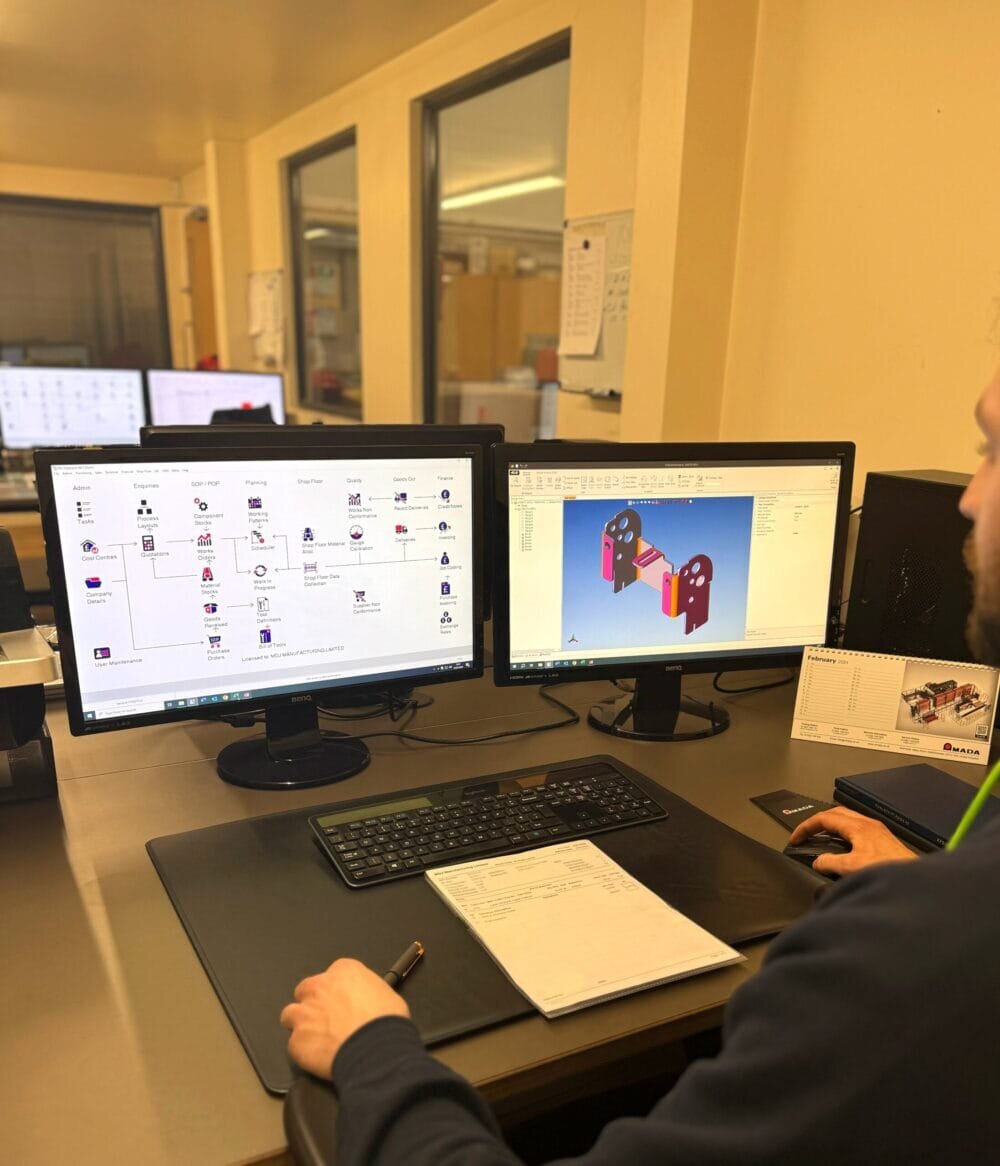

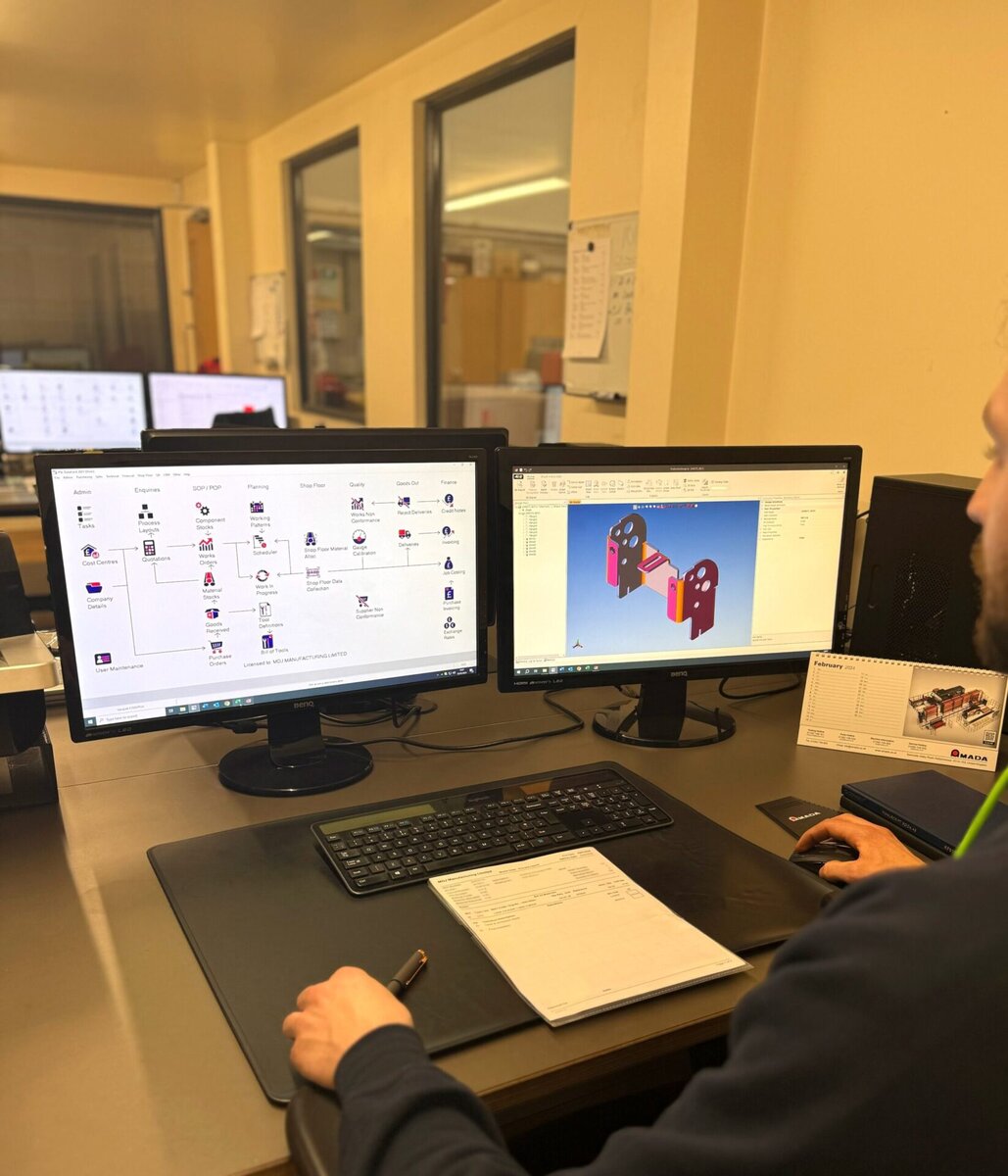

Success in the dynamic industry of subcontract precision engineering lies not only in cutting-edge technology but also in efficient management systems. For Derbyshire-based MDJ Manufacturing Limited, the journey towards operational excellence took a significant leap with the adoption of PSL Datatrack production control software.

Prior to implementation of the modular system, staff at all levels were spending far too much time manually processing paperwork and checking component and material stock levels. “PSL Datatrack has totally improved our efficiency within the manufacturing process, enabling us to spend more time on customer communication and quality monitoring,” comments Dave Trow, owner of MDJ.

Established in 1995, MDJ specialises in the production of high-quality metal fabrications catering to various industries. Its commitment to collaborative partnerships, understanding unique needs and delivering tailored solutions, has positioned the business as leaders in its field. The company’s impressive facility houses state-of-the-art fabrication technology with laser cutting, punching, press braking, welding, tube bending, section rolling and finishing services all offered.

MDJ prides itself on establishing long-term partnerships with both customers and suppliers and its investment in PSL Datatrack reflects its dedication to staying ahead of the curve. Strong ties with suppliers ensure a seamless supply chain which allows MDJ to thrive on production/repeat work and absorb high-demand scenarios effectively.

The decision to invest in PSL Datatrack came after a recommendation from an existing MDJ customer. After a thorough visit and product demonstration, MDJ recognised PSL Datatrack as the ideal solution to meet its production control requirements. “The modularity of the system, allowing users to start at a basic level and expand as needed, aligned perfectly with our commitment to adapt to evolving customer demands,” Dave says.

MDJ utilises various PSL Datatrack modules covering administration, sales, purchasing and finance to monitor real-time progress. Detailed reports included as part of the standard PSL Datatrack package enable the business to meet customer cost, delivery and quality expectations with greater success. “Accurate and professional invoicing is much quicker than our previous method and ties in seamlessly with our accounting software,” continues Dave.

As an ISO 9001:2015 accredited business, traceability is essential for MDJ. Dave remarks that PSL Datatrack has enabled the company to monitor material and component movements throughout the factory with greater precision. Receipt of purchased goods and works order progression is also monitored in more detail than was previously practical.

Investment in PSL Datatrack has also meant that all documentation and paperwork is now presented in a clear and consistent format across the board. “This, coupled with constant investment in machinery and technology, help us to maintain a competitive edge with improved efficiency, accurate costs and precise lead times,” Dave comments. The result is a company that consistently delivers world-class products which exceed industry standards.

Expressing his satisfaction, Dave confirms: “We would be happy to recommend PSL Datatrack to any similar business seeking to improve business efficiency and manufacturing quality with production control software.” As an organisation that aims to never stand still, MDJ plans to utilise additional PSL Datatrack modules in future to further streamline its entire production process.

The modular structure of PSL Datatrack stands out as a great benefit. The ease of use and remote training provided were praised by MDJ’s office staff, with many users requiring only basic understanding to get started with the system. The exemplary support provided by PSL Datatrack’s UK-based team ensures that any queries are resolved quickly and efficiently by email, phone or screen sharing.

MDJ Manufacturing Limited therefore exemplifies how implementation of PSL Datatrack can result in substantial improvements to operational efficiency, traceability and overall customer satisfaction. For subcontract precision engineering companies seeking a competitive edge, this success story serves as a compelling testament to the transformative power of modern production control software.

For more information, visit www.psldatatrack.com or contact PSL Datatrack, Lily Hill House, Lily Hill Road, Bracknell, Berkshire, RG12 2SJ, Tel: +44 (0) 1344 827312, Email: [email protected]