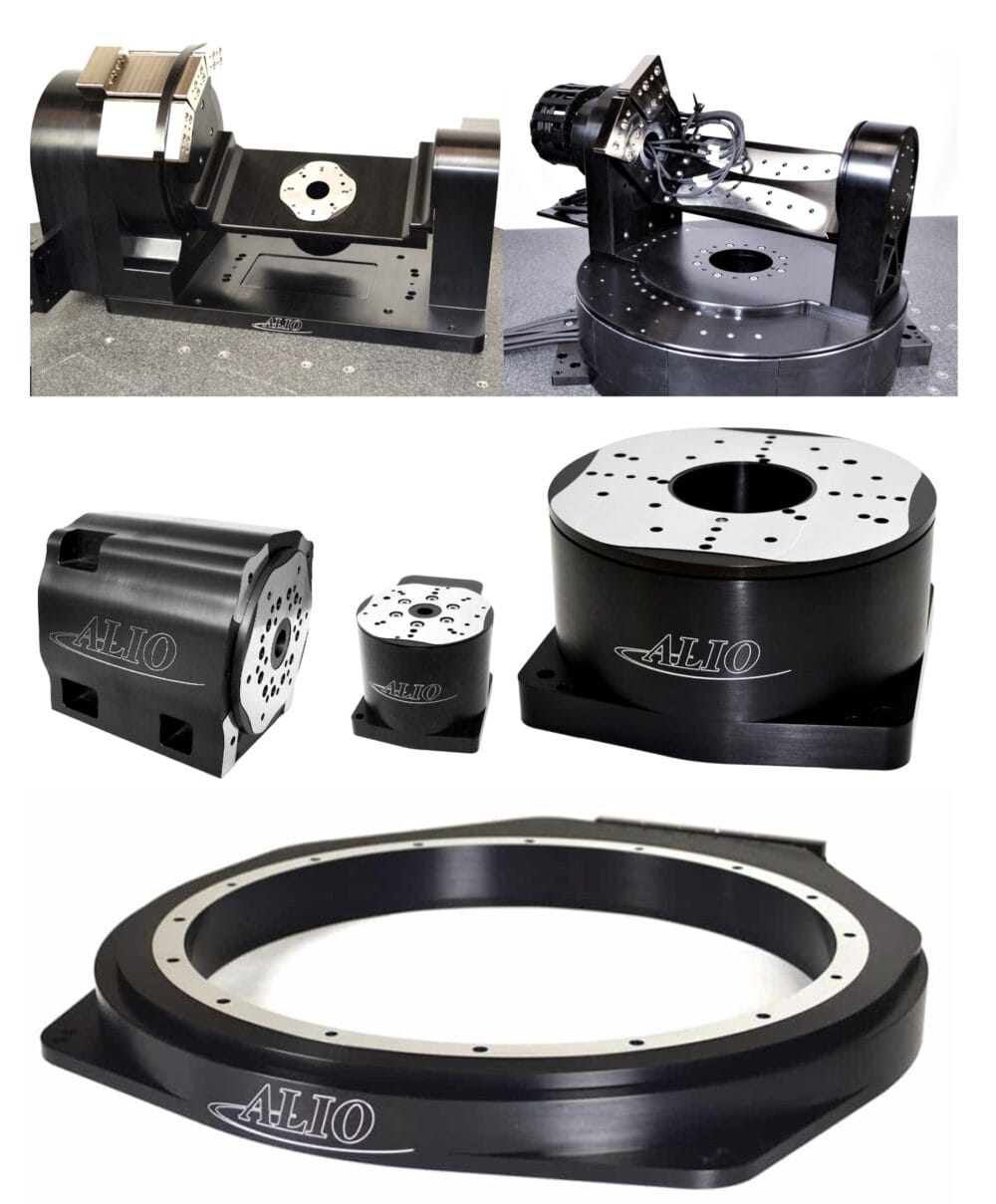

With over 20 years working in the area of nanometer-level motion control, ALIO Industries continues to develop TRUE NANO® precision rotary stages to meet and exceed today’s demand for high precision rotary motion.

ALIO’s mechanical bearing rotary stages are designed with crossed roller bearings for improved stiffness for offset loads and rotational precision. Integrated with servo torque frameless motors, these stages can handle applications where the mass and acceleration needs are extreme, while still maintaining nanometer-level precision performance.

Bill Hennessey, President of ALIO Industries says, “ALIO’s focus on materials and machining is absolute in the manufacture of our rotary product line, just as it is with its linear products, ensuring the bearings and metal are located in ultra-machined parallel surfaces as shown by the machined lands on all stages. Standard ALIO rotary stages have 0.2 arc-second repeatability with options for more precision. Through the use of different bearing selections from air to mechanical balls or rollers we can meet or exceed all demanding rotational precision needs, with continuous radial runouts standard at 10 to 20 microns and many below 5 microns depending on application needs. I would advise customers to beware of specifications on rotational stages that only move back and forth +/-170 degrees, as this does not paint an accurate picture of the stage’s precision for full rotation.”

ALIO’s mechanical bearing rotary stage family has multiple motor sizes to meet different duty cycles as well as mass and acceleration needs from 80 mm to 300 mm in diameter. Vacuum rotary union options are available on the inner diameter for mounting a vacuum chuck.

ALIO has also designed mechanical bearing rotary stages with angular contact bearings representing the most compact design on the market. Integrated with servo ironless motors, these stages best fit metrology applications where small angular adjustment is needed with nanometer-level precision performance.

When ultra-tight run-out precision motion is needed, manufacturers can choose from ALIO’s continually growing line of air bearing rotary stages. Whether it is exceptional stiffness or cost-effective motion that is the priority, ALIO Industries can offer a variety of options to meet the needs of today’s nano-precision applications.

Hennessey continues, “Incorporating ALIO’s industry-leading torque ratings, our two-axis gimbal rotary systems are capable of high rotational speeds while maintaining the stand-out precision levels expected from ALIO’s systems. Metrology, laser processing, additive manufacturing, and many other industry sectors have benefited from these ALIO products, and air purge is incorporated for contaminant protection and longer life. Internal cable and air line routing provide an extremely clean finished product. We recommend that you contact ALIO to discuss how we are working tirelessly to meet your demand for ultra-precise rotary motor control systems,”