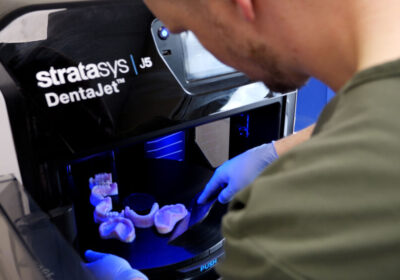

The high-performance OLCT 100-XP-MS range of flammable gas detectors from Teledyne Gas and Flame Detection now incorporates cutting-edge MEMS (Micro-ElectroMechanical Systems) sensor technology. Delivering the market’s most accurate readings for over 14 of the most common combustible gases and gas mixes — including hydrogen, methane, propane and butane — MEMS technology adds to the capabilities provided by conventional sensors. Users also enjoy notable advantages regarding ‘poison’ immunity and operating life, particularly in environments that sometimes prove challenging for catalytic sensors.

Traditionally, industry professionals select a flammable gas detector housing a catalytic sensor calibrated for a specific gas, or an infrared (IR) sensor. Although these conventional solutions are still highly beneficial, they are not always optimal. Catalytic sensors require bump testing, for example, to check they remain free from sensor poisoning, while IR technology is unable to detect hydrogen. The use of Hydrogen is rising as the focus to find a cleaner alternative to natural gas continues across the industry, in turn driving the need for high-capability hydrogen detection solutions.

MEMS technology take gas detection to an even higher level of capability, providing precise readings in % LEL correlated with the specific gas or blended gas/vapour clouds present in the environment. By offering catalytic oxidation, IR and MEMS sensor technologies in a single device, the OLCT100-XP-MS represents a holistic solution that provides a revolution in flammable gas detection, regardless of environmental or operational constraints.

Ideal for use in energy sectors, including petrochemical and oil and gas, the new OLCT100-XP-MS also offers multi-gas protection in applications that include lithium-ion BESS (Battery Energy Storage Systems), industrial manufacturing, wastewater treatment and fire response.

“Our flammable gas detector with thermal conductivity technology supported by MEMS sensor provides accurate, automatic readings without correction factors, along with automatic gas classification,” says Régis Prévost, Product Line Manager, Teledyne Gas and Flame Detection. “Delivering unprecedented reliability and accuracy, the device reduces false alarms thanks to integral compensation for environmental parameters that include temperature, pressure and humidity.”

In some environments, extreme pressure, temperature and humidity can damage or even poison other sensor types, compromising performance and incurring unwanted cost. In contrast, MEMS sensor technology is poison-immune, operating reliably with an integral self-test for failsafe operations and complete peace-of-mind.

“With its robust design and highly engineered construction, our low-maintenance OLCT100-XP-MS comes with a two-year warranty,” says Régis Prévost. “Indeed, such is our confidence in this innovative flammable gas detector that users can expect many years of reliable and accurate operation in the most demanding industry applications.”

For more information, visit www.teledynegasandflamedetection.com or contact gasandflamedetection@teledyne.com