Global engineering technologies company, Renishaw, attended the Additive Manufacturers Users Group (AMUG) conference 2024, from March 10th to 14th in Chicago, USA. During the event, Renishaw showcased the benefits of its latest AM technology, as well as a talk hosted by Additive Manufacturing Applications Engineering Manager, Kevin Brigden.

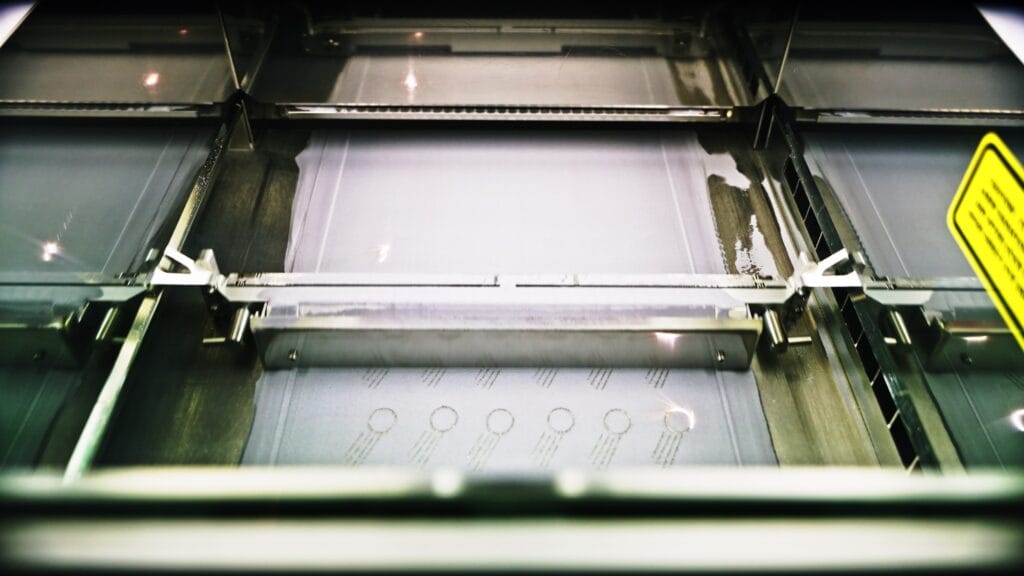

An AM build in progress on a RenAM 500 fitted with TEMPU Technology

Brigden hosted a platinum speaker session on Monday, March 11th to share the productivity improvements being seen from the development of Renishaw’s TEMPUS™ technology, an upgrade now available for the company’s RenAM 500 series of metal additive manufacturing (AM) systems. Productivity is a known hurdle to the mass adoption of AM technologies, including metal laser powder bed fusion. However, by allowing the system lasers to fire at the same time as the recoater is moving, TEMPUS technology can save up to 50% of build time (depending on build geometry). What’s more, this additional process speed requires no compromise in part quality.

At the AMUG conference, attendees saw demonstrations of a Renishaw RenAM 500Q system with TEMPUS technology, as well as a display of parts printed on the system to showcase its capabilities. For example, by using TEMPUS technology, Spanish metal AM specialists MADIT were able to reduce build time on a tubular automotive component from 13 hours, 43 minutes to under seven hours. Visitors also saw other parts produced on the new system, including advanced material parameter sets enabling low overhang prints, and craniomaxillofacial (CMF) implants from KLS Martin. Certified FAA Class 1 components in titanium from Tronosjet Maintenance were also on display to demonstrate the breadth of capabilities of Renishaw’s AM offering.

“AMUG is a great opportunity to network and share advancements with other AM users across various industries,” said Kevin Brigden. “We had the opportunity to share the technological fundamentals of the RenAM 500 system processes and highlight our initial findings from the introduction of TEMPUS technology, as well as discover what others in the industry are developing.”

The RenAM 500 series of metal AM systems is configurable with one (500S) or four (500Q) high-power 500W lasers, and automatic or flexible (Flex) powder and waste handling. Launched at Formnext 2023, the RenAM 500 Ultra is the latest addition to Renishaw’s RenAM 500 series of metal AM systems. The RenAM 500 Ultra builds on the successful RenAM 500 series and offers new TEMPUS technology and advanced process monitoring.

AMUG aims to bring together people in the AM industry to share expertise, best practices, challenges, and application developments in additive manufacturing.

For further information on the RenAM 500 series, visit https://www.renishaw.com/en/renam-500-metal-additive-manufacturing-3d-printing-systems

AM Parts produced by Spanish customer Madit using TEMPUS technology