Tapping into new opportunities in fusion energy, battery technology and specialist R&D projects has helped a Huntingdon-based specialist metals and material supplier boost sales by recording annual double-digit growth since receiving private equity investment.

Goodfellow, which employs more than 100 people at its Ermine Business Park facility, has overcome global issues with supply chain disruption and rising energy prices to post a £4m rise in turnover in the first full two years following its acquisition by Battery Ventures.

This growth has been achieved by the firm’s ongoing investment in stockholding, its expert team of technical scientists and bespoke processing services that continue to be a valuable resource for R&D departments and scientific specialists looking to push the boundaries of innovation that achieve cutting-edge applications.

Simon Kenney

“Our specialist materials are used in some of the world’s most challenging projects, and we often tend to be a critical partner to emerging global sectors and we are seeing this with electrification and high-profile fusion technology,” explained Simon Kenney, Chief Executive Officer of Goodfellow.

“There is no doubt that this track record has been crucial in helping us reverse a general downturn in our sector to continue to grow over the last twelve months and we have to tried to leverage our market position by introducing three new ranges last year, including Custom Alloy Powders, Microfoils and Rare Earth Oxides.”

He continued: “This year we are hoping to introduce Metal-organic Frameworks (MOFs) to our offer and, due to their tunable large surface area and high porosity, can be used for applications including catalysis, carbon capture adsorption processes, gas sensors, energy storage and drug delivery systems.”

2024 will be another big year for Goodfellow, with a new brand and website launch planned for early April that will better reflect the company’s expanding global reputation whilst supporting customers’ needs to buy products online.

There will also be the culmination of a significant investment in a new ERP system that is being installed to support the firm’s complex range of 170,000 catalogue products and the growing success of its bespoke processing services.

Simon, who joined the business in 2016 continued: “The improvements we are making this year are all about improving the customer experience, whether that is shortening already industry-best lead times or making sure technical data is easier to access through our new online platform.

“We offer nearly 98% of our stock range within 48 hours and with no minimum order quantities, which means we can supply small organisations with materials quickly for prototype work, and also large institutions that are challenging the way we create and store energy, power transport and save lives.”

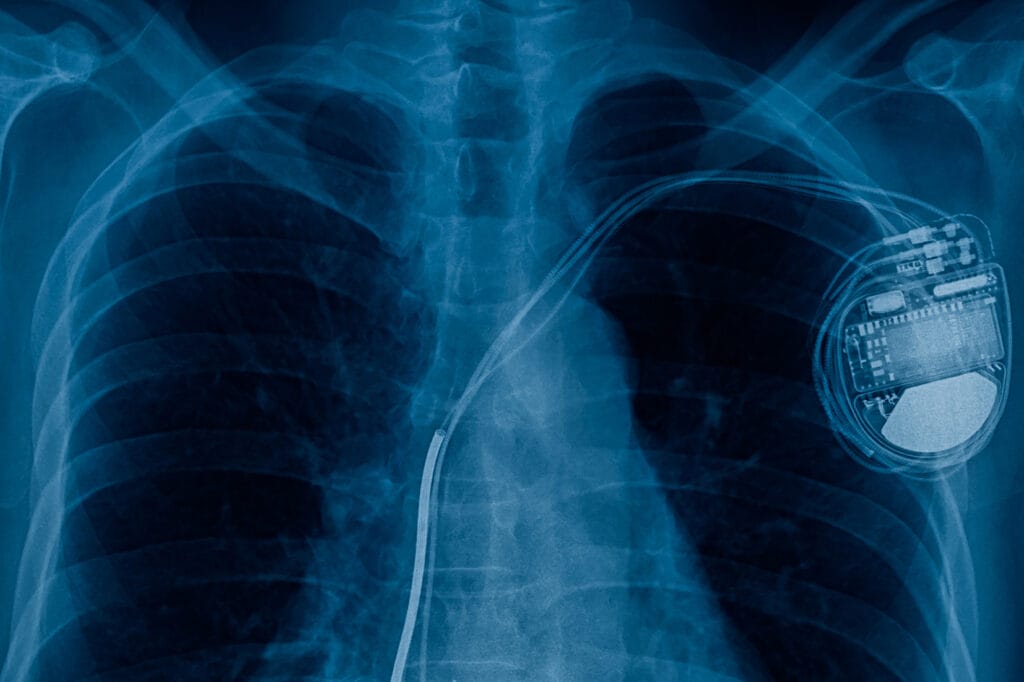

He concluded: “There are massive strides being made in the medical field, which are leveraging the properties of our innovative materials and Goodfellow’s design process that provides samples and technical support to aid development of new solutions. This includes innovation in cochlear implants and pacemakers.”

pacemaker cell x-ray image

Goodfellow is expecting to achieve a similar level of growth this year through organic increases in sales and the possibility of future acquisitions.

For further information, please visit www.goodfellow.com