A precision component specialist has posted a 10% increase in sales after making the most of a ‘reshoring boom’,

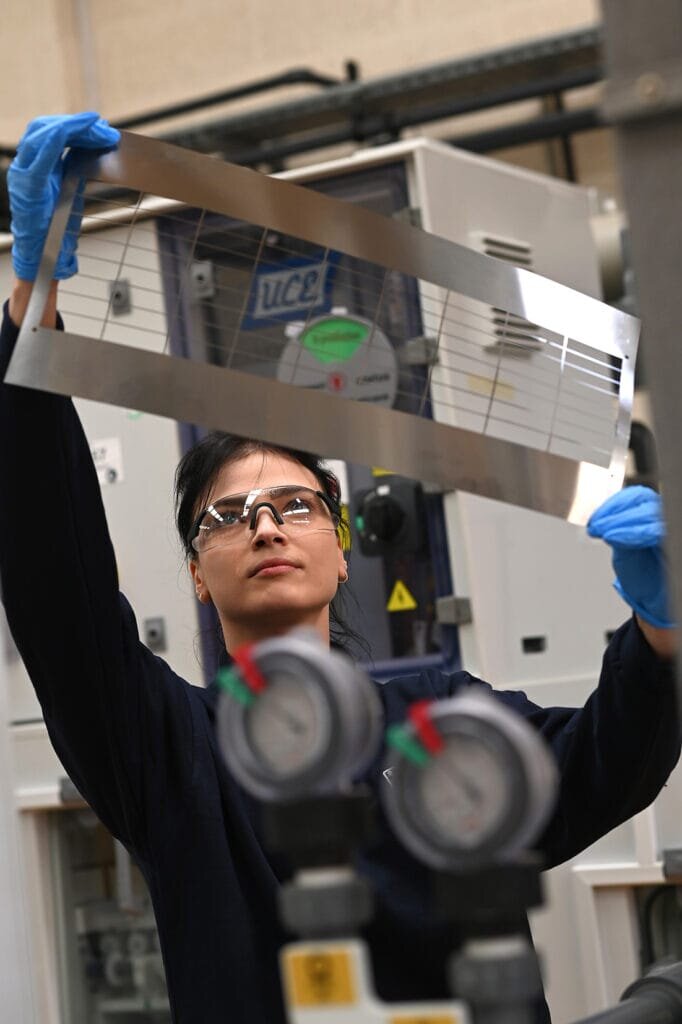

Advanced Chemical Etching (ACE), which supplies parts to customers in aerospace, automotive, electronics, general engineering, medical and telecoms, has secured £800,000 of new orders from companies looking to tap into exacting quality and new product development expertise.

The Telford-based company has seen a significant rise in fuel cell projects and several new projects increasing in volume by 25%, all setting the scene for an anticipated drive to achieve £10m sales this year.

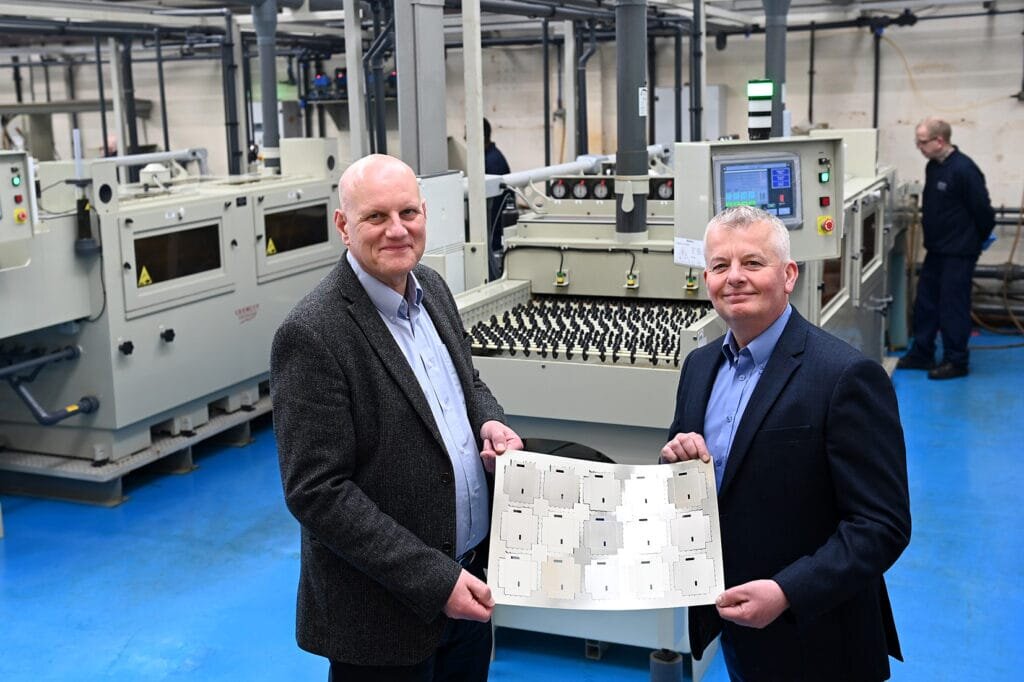

This push will be boosted by the ramping up of two ‘Chemcut’ etching machines at its Hortonwood 33 facility, giving it a major boost in capacity and faster turnaround times.

Ian Whateley, Managing Director, commented: “There is so much manufacturing innovation in the UK and we are finally seeing other countries switch back on to what we offer here.

ACE Telford

Copyright 2023 © Sam Bagnall

“In addition to sales, there has also been a 10% increase in the number of new projects we are involved in and, all of these, are looking for a strategic partner that can work with them from design through to early-stage prototyping and low and medium volume supply.”

He continued: “Export now accounts for nearly 30% of our annual turnover and we’re seeing really strong demand from Austria, Germany, Switzerland and our traditionally strong markets of Belgium and the Netherlands.

ACE Telford

Copyright 2023 © Sam Bagnall

“There are also new opportunities coming in from the Far East and the US and this, alongside strong demand from our domestic customer base, is something we want to explore further with our two ‘Chemcut’ machines nearly up and running.”

The scope of ACE’s activities is far and wide and can include anything from safety critical components for aircraft and F1 cars, to meshes and electronic connectors, battery interconnectors, fuel cell bi-polar plates, cooling plates and heat exchangers.

ACE Telford

Copyright 2023 © Sam Bagnall

All parts are developed and manufactured at its main site in Telford and at the company’s dedicated sister business, ACE Forming Limited, in Kingswinford.

This means the business is in a rare position of being able to etch or form parts to meet the customer’s cost point and, importantly, the desired performance of the end application.

Chris Ball, Executive Director of Advanced Chemical Etching, went on to add: “We’ve seen volumes surpass where they were before the pandemic, with aerospace gathering pace as airport traffic surges.

“The opportunities are out there, and we have taken the decision to not only invest in the latest etching technology, but also increase our workforce with eight new people recruited in the last twelve months alone.”

ACE Telford

Copyright 2023 © Sam Bagnall

He concluded: “£10m sales threshold is definitely in our sights for 2024, as we continue to put Shropshire on the global manufacturing map.”

Advanced Chemical Etching has just kicked-off accreditation to the aerospace AS9100 process, with the initial audit taking place in February and approval due to be completed by May this year.

For further information, please visit www.ace-uk.net or follow ACE on social media.