In its center of competence, the SKZ research team for plastic materials in Würzburg concentrates on research and training in the field of 3D printing. A large portion of the work concerns post processing. To better deal with this subject SKZ recently purchased an S1 shot blast system from AM Solutions – 3D post processing technology. Among other things SKZ analyzes the effects of different blast media on the surface finish as well as their efficiency and the consistency of the shot blasting results.

As one of the largest research institutes in its field the SKZ center for plastic materials studies not only different materials but also the underlying manufacturing processes. In this respect the 3D printing technology, which in recent years has undergone phenomenal growth, plays a significant role. For this reason, SKZ maintains a separate center of competence, the center for additive manufacturing, in Würzburg. This organization handles not only numerous research projects but also develops training programs to familiarize interested companies with the 3D printing technology, be it for prototyping but also for volume production. Especially, when it comes to producing large work piece volumes, the post processing of the printed components is a key manufacturing stage. To be able to study post processing in more detail, SKZ invested in a S1 shot blast system AM Solutions – 3D post processing technology.

Kevin Popp, senior scientist for additive manufacturing at SKZ explains: „In our research with new materials for powder bed based additive manufacturing the post processing stage is an extremely important subject“. Mr. Popp continues: „For example, right now we study the effect of different blast media on the surface finish of different plastic materials. For this purpose, SKZ is utilizing the S1 system. We are particularly impressed by how adaptable this system is for our post processing activities, for example, how simple it is to exchange the blast media.“ With its easy, uncomplicated blast media exchange the S1 allows us to create quick and direct comparisons between different media such as glass, ceramic or poly beads.

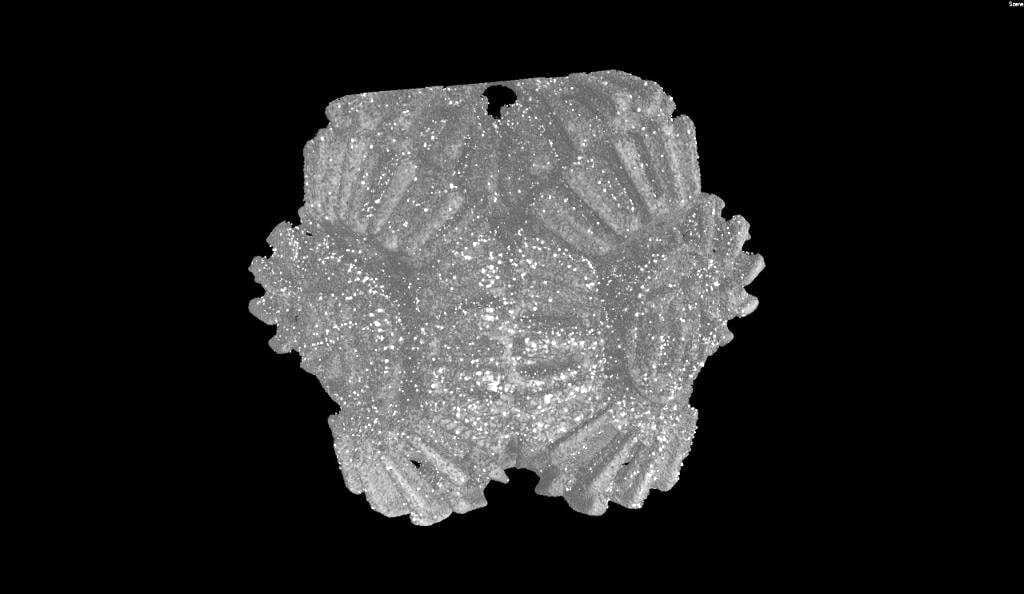

With a CT scan the effects of different blast media on the surface finish can be precisely analyzed. For example, in the case of orthotic or prosthetic implants micro fine glass debris, created by the impact of glass beads on the work pieces, must be prevented at all costs. For such applications other blast media like poly-beads are much more suitable. SKZ also analyzes and documents the surface qualities produced by different processing parameters, for example, the settings of the blast nozzles. All these empirical findings are extremely valuable for companies who want to establish 3D printing in their manufacturing operations.

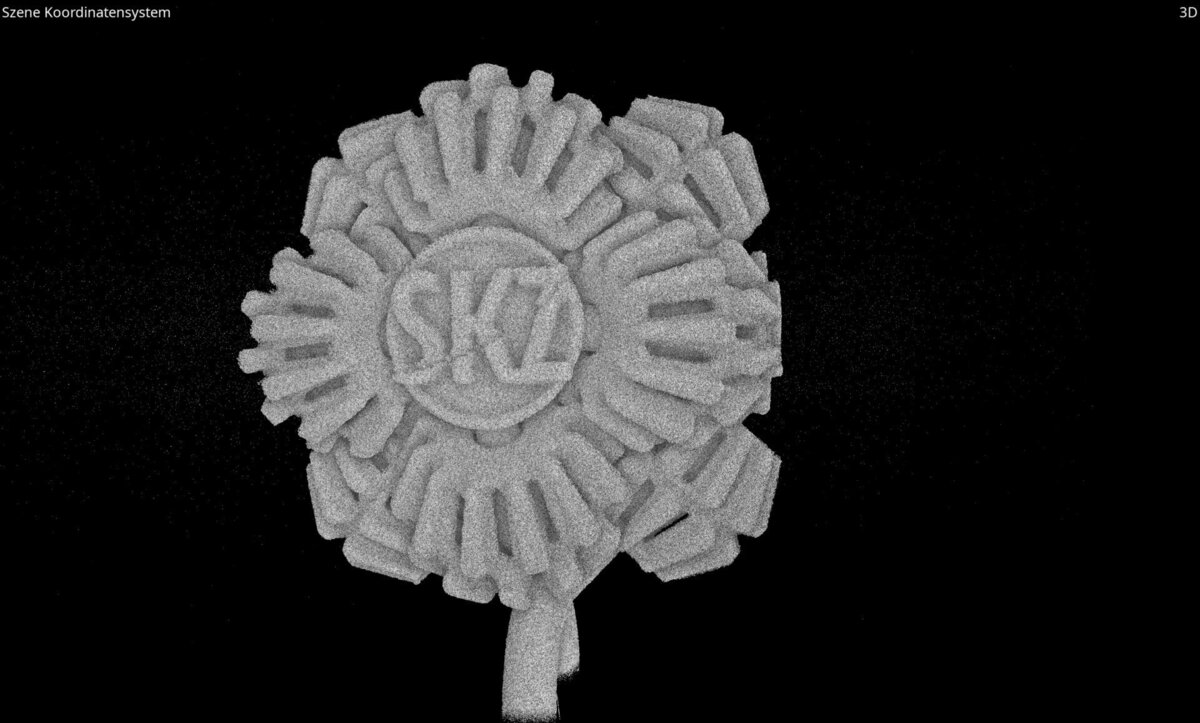

SKZ use the S1 to study the effects of different blasting media on surface quality. The brain gear on the left is blasted with glass beads, clearly showing injection and uneven surfaces. In the picture on the right side, the brain gear is blasted with polybeads, resulting in a significantly much more homogeneous surface.

Processing of 300 components in in only 15 minutes

„For volume production the repeatability of the results and time are essential parameters, which we study carefully“, explains Popp. „With our manual shot blasting operations the surface finishes were all over the board. The S1 produces consistent surface finishes on large work piece volumes, even on extremely complex components like brain gears with their delicate gear tooth geometries. In the past it took us a whole day to blast 300 pieces. And the results were highly inconsistent. Today we just need 15 minutes for the same work piece volume, with excellent, consistent surface finishes.“ Of course, such information is very important for the creation of suitably efficient process chains. „We consider ourselves as pathfinder for additive manufacturing and want to guide the people to this technology in a sensible manner”, comments Popp.

Excellent cooperation

For a research institute like SKZ good cooperation with its partners is essential. Popp concludes: „With AM Solutions we have found a partner with decades of experience in post processing, with whom we can openly discuss our issues and jointly develop suitable solutions. Such a wealth of knowhow is a big help to us, and the short geographical distance between our two organizations allowed us to test the machine and the blast media beforehand in Untermerzbach.” This represents no doubt the basis for a long and productive partnership.

Kevin Popp is delighted with the new system: “The S1 produces consistent surface finishes on large work piece volumes, even on extremely complex components like brain gears with their delicate gear tooth geometries. In the past it took us a whole day to blast 300 pieces. And the results were highly inconsistent. Today we just need 15 minutes for the same work piece volume, with excellent, consistent surface finishes.“

You will find further information under: www.solutions-for-am.com

For over 80 years, the privately owned Rösler Oberflächentechnik GmbH has been actively engaged in the field of surface preparation and surface finishing. As global market leader, we offer a comprehensive portfolio of equipment, consumables and services around the mass finishing and shot blasting technologies for a wide spectrum of different industries. Our range of about 15,000 consumables, developed in our Customer Experience Centers and laboratories located all over the world, specifically serves our customers for resolving their individual finishing needs. Under the brand name AM Solutions, we offer numerous equipment solutions and services in the area of additive manufacturing/3D printing. Last-but-not-least, as our central training center the Rösler Academy offers practical, hands-on seminars to the subjects mass finishing, shot blasting and additive manufacturing. The Rösler group has a global network of 15 locations and approx. 150 sales agents.

For more information, please go to: www.rosler.com