Today, our understanding of the “Smart Factory” is unequivocally linked with deep learning and AI. This is very different to our understanding of the concept fifteen years ago, when the first visions of the Smart Factory of the future emerged. What became of these early visions? And where are we today? Here, Mark Clemens, Connectivity Architect and Security Strategist at COPA-DATA, explains the shifting vision of a smart factory.

Today, our understanding of the “Smart Factory” is unequivocally linked with deep learning and AI. This is very different to our understanding of the concept fifteen years ago, when the first visions of the Smart Factory of the future emerged. What became of these early visions? And where are we today? Here, Mark Clemens, Connectivity Architect and Security Strategist at COPA-DATA, explains the shifting vision of a smart factory.

We lack a globally accepted definition of “Smart Factory”. Further, what we label as “the factory of the future” today is likely to be different to the concept 10 years from now. And this shifting definition is but one complication. The term also implies an end state which, once reached, provides no further room for improvement. Surely the Smart Factory built 10 years ago has become smarter since? Likely, it’s seen improvements due to further investment and by making better use of available information. I, therefore, prefer the term “Smarter Factory”.

The goal of a Smarter Factory is achievable in small steps, with the chance to learn while doing. A Smarter Factory approach can also be applied to existing factories – whether there is already technology, automation, and data collection in place or not. While one can debate the argument, I think that making an existing factory smarter is much more easily achievable than building a new Smart(er) Factory from the ground up.

But where to begin?

It definitely makes sense to define a Smarter Factory strategy from which small achievable goals can be derived. This allows for an iterative, agile approach. Many topics can be worked on in parallel, rather than starting one big project for which the benefits may be hidden from the business for a long time. It is key to get people involved from different domains from the very beginning, especially when improvements could make some job roles superfluous. The involvement and outlook of different roles in an agile process provides future perspective and reduces the risk of efforts being sabotaged.

Let’s take one example where there are quick wins to be had: a company thinking about net zero and how to move from fossil fuels to electrification. One challenge is the grid connection which cannot quickly be upgraded to the necessary capacity by the electricity provider. Not doing anything is not an option. Local generation, in combination with storage, could be a viable option if you know what your energy consumption looks like and where peaks can be shaved. Such an effort fits into a Smarter Factory strategy and it starts with information that may not be readily available from everywhere.

Make smarter use of existing information

Rather than installing energy meters at every piece of equipment, interrupting production processes, the energy consumption of a piece of equipment may, for example, be derived from an existing sensor that is used for some other purpose in its PLC program. Other equipment energy consumption may be measured once so that subsequent consumption can be extrapolated from the operating hours of the equipment as provided by daily manual recordings.

Experienced shop floor workers probably know the conditions when equipment is running but could be idle. When existing intelligence is used smartly a lot can be gained. Nevertheless, at some point, it will be necessary to implement automated data collection. Maintenance staff and system integrators with networking experience are perhaps best equipped to help define where the installation of new measuring devices would be most efficient and most easily achieved. IT can provide the necessary data repositories and backups while ensuring cyber security.

Get the data structured and harmonized

While I have tried to avoid using buzzwords so far, I would like to introduce a paradigm that some may consider a buzzword: edge computing. Data can be collected from many energy meters and other devices as fast as 100 milliseconds, generating large amounts of data.

While I can agree that data is the new gold, this idea does need to be put into perspective. It’s gold when you have the right kind of data to answer a pressing question. Of course, the price of gold fluctuates with the trends in the worldwide economy, interest rates, and the nervousness of investors. Similarly, the value of data also fluctuates. Energy consumption data has less value when energy prices are low. It’s worth more during an energy crisis. And having huge amounts of consumption data without context related to other sensory and production information, may even prove to be as valuable as fool’s gold.

Deriving real value

Many energy meters provide their information through the Modbus protocol. It has no mechanism for conveying timestamp information or quality information. Challenges around data consistency must also be considered. When an energy meter needs to be replaced, a sudden change in the energy consumption reading can throw off downstream logic, algorithms and reporting. While standards are emerging for unifying information over Modbus – such as Sunspec – not all meters support this. Other data used as virtual energy consumption data needs some transformation and harmonization in order to be useful.

Ideally, data should be reduced to only what is needed downstream for visualization, reporting, and decision making. All these tasks can be performed or computed locally, close to production, i.e. at “the edge”. With COPA-DATA’s software platform, zenon as your edge computing engine, it’s easy to provide qualified, timestamped, harmonized, aggregated, consistent, and context-related data. With zenon version 12 available on Linux for selected communication protocols and functionality, it’s even easier.

The future’s smarter factories

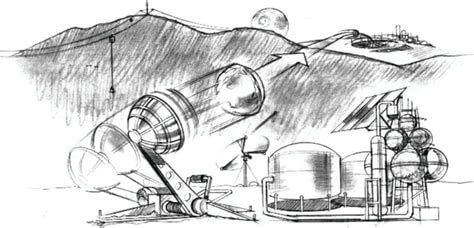

A fully autonomous, self-optimizing, self-maintaining, self-healing, perpetual process factory may today be science fiction. But, in future, we will be needing factories that are smarter still. Think of facilities operating on the ocean floor in the deep sea or on the moon to produce oxygen or hydrogen. These Smart Factories of the future will be an even bigger challenge!